Adjustment

14 - 43

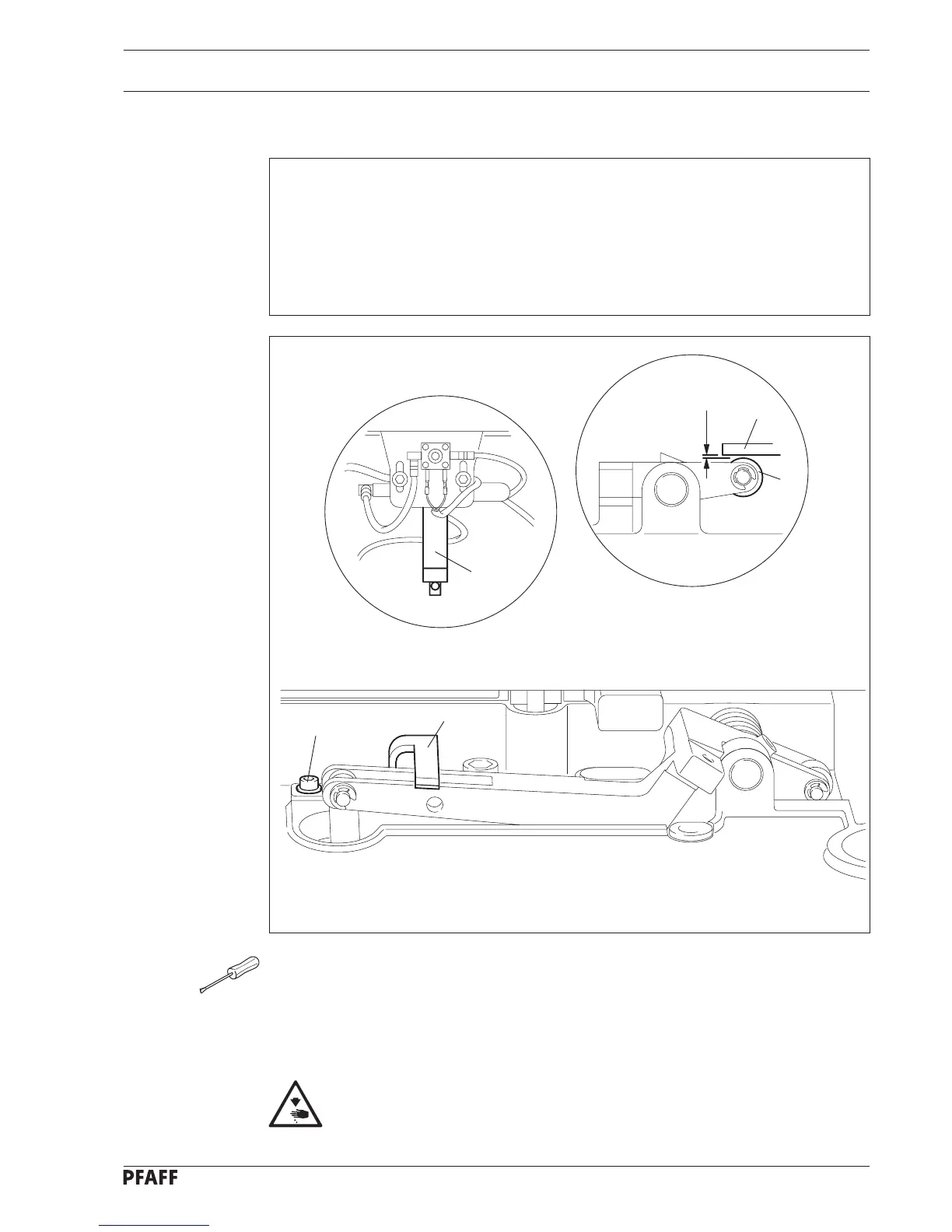

Fig. 14 - 41

0,5 mm

3

1

6

5

4

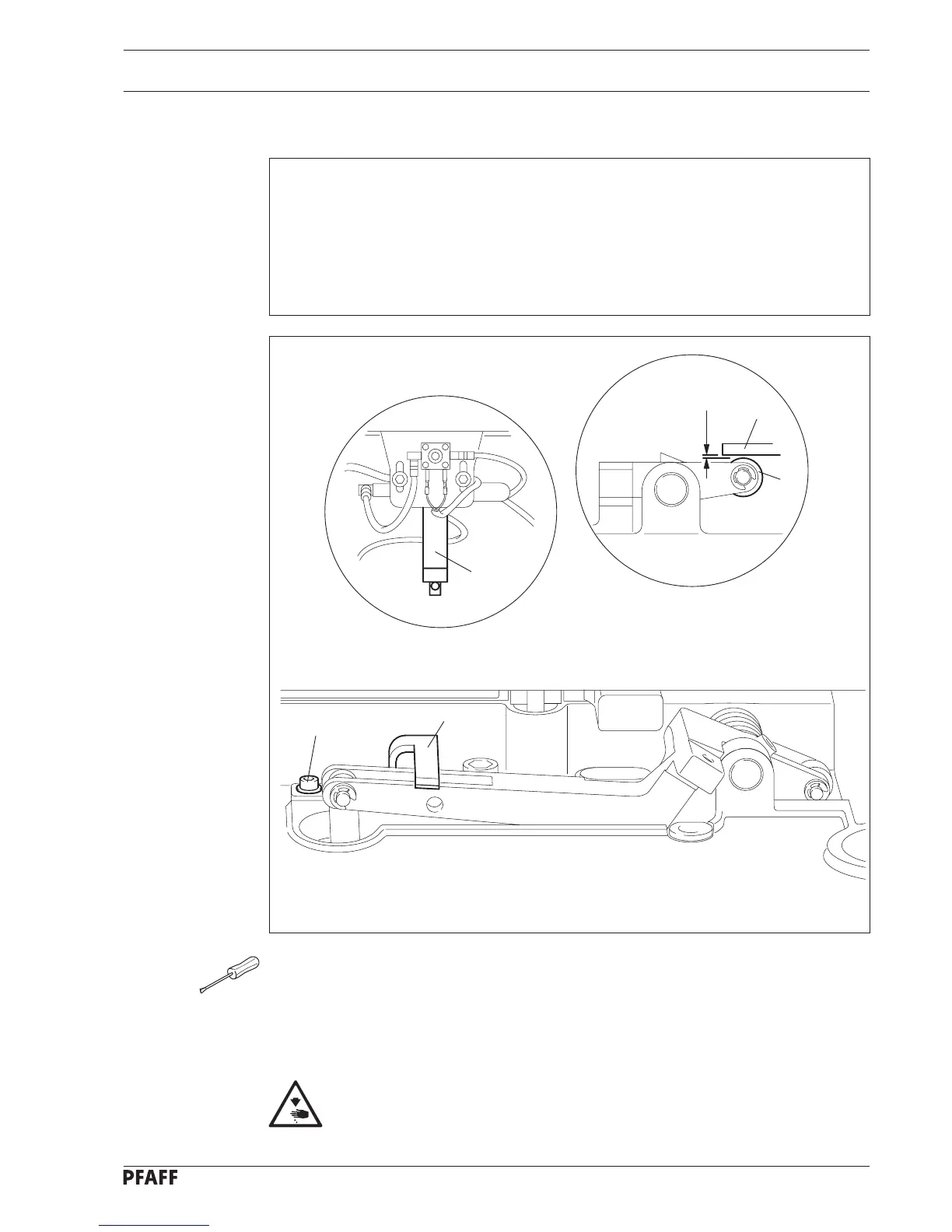

● Lay the machine head on its side.

● With the feed lifting cylinder 1 extended, loosen the screws 3.

● Move the angle bracket 4 in accordance with requirement 1.

● Tighten screws 3.

● Return the machine head to its upright position.

Danger of crushing between machine head and table top!

14.19 Feed lifting cylinder

Requirement

1. With the feed lifting cylinder 1 extended there must be a clearance of 0.5 mm between

the presser roller and the pressing surface of the lever 6.

2. With the feed lifting cylinder 1 retracted ( see fig. 14.42 ), the lever 2 of the work

clamp must be able to be lifted a little more.

3. With the feed lifting cylinder 1 retracted, the work clamp must rise 12.5 mm from the

feeder.

Loading...

Loading...