CLUTCHING

6.12

Moveable Sheave Bushin g Inspection

2. Inspect the Teflont coating on the moveable

sheave bushing.

Teflont

Moveable Sheave Bushing Inspection:

Replace the cover bushing if more

brass than Teflont is visible on the

bushing. Refer to bushing replace-

ment in this chapter.

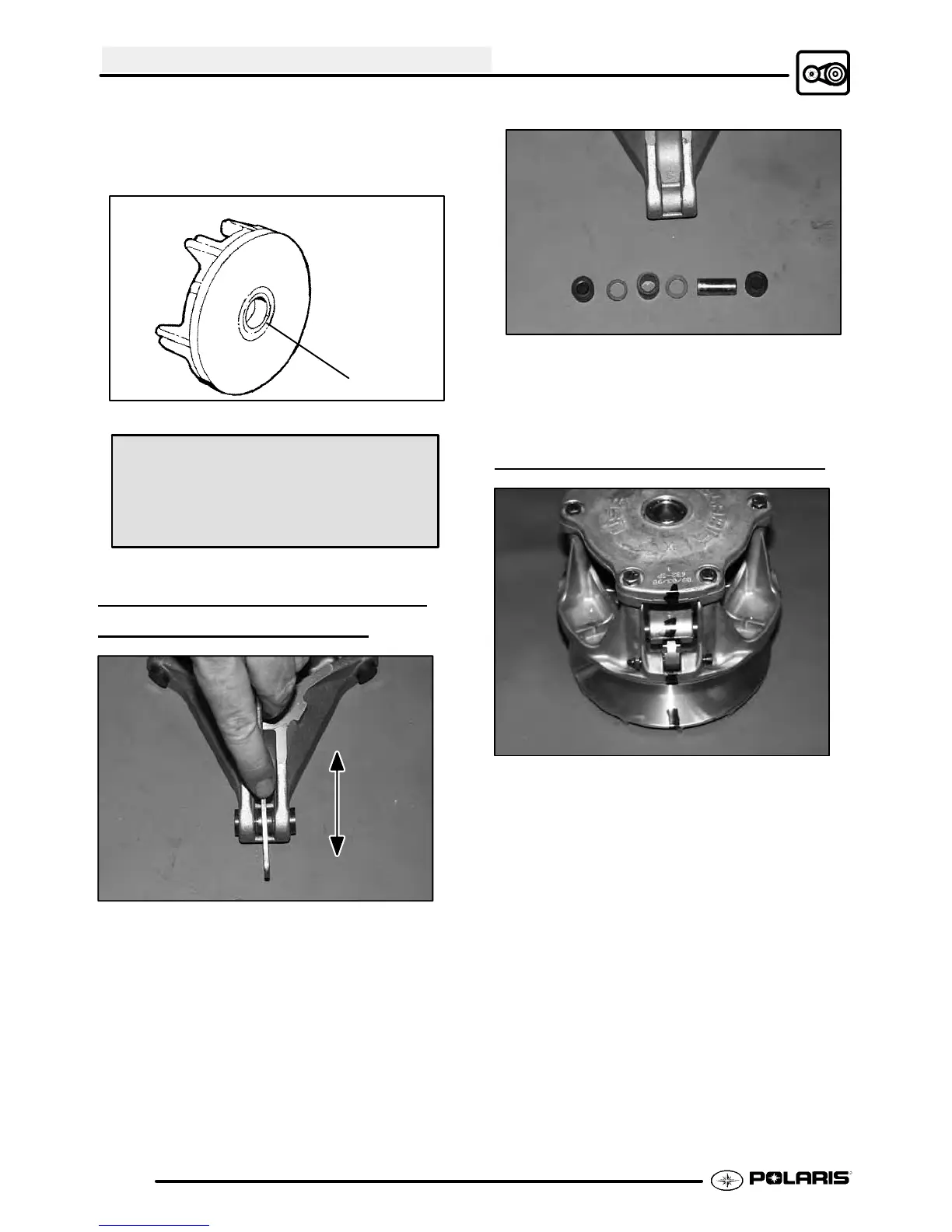

ROLLER, PIN AND THRUST

WASHER

INSPECTION

1. Inspect all rollers, bushings and roller pins by

pullingaflatmetalrodacrosstheroller. Turnroller

with your finger. If you notice resistance, galling,

or flat spots, replace rollers, pins and thrust

washers in sets of three. Also inspect to see if

roller and bushing are separating. Bushing must

fit tightly in roller . Use the Roller Pin Tool (PN

2870910) to replace rollers and pins. Take care

nottodamagerollerbushingorbearing surfaceof

the new pin during installation.

2. Rubber backed buttons can be used in all ATV

clutches if the hollow roller pin is changed to the

solid roller pin. NOTE: The rubber side of the

button is positioned toward the solid roller pin.

DRIVE CLUTCH ASSEMBLY

NOTE: It is important that the same number and

thickness of washers are reinstalled beneath the

spider during assembly. The Teflont bushings are

self-lubricating. Do not apply oil or grease to the

bushings.

1. Reassemble drive clutch in the following

sequence. Besurethe“X”,orthemarksthatwere

made earlier, are aligned during each phase of

assembly)

a)“X”,orthemarksthatweremadeearlier,on

cover

b) spider, making sure spacer washers are

installed underneath spider and

positioned properly in recess

Loading...

Loading...