MAINTENANCE

2.31

G Replace any worn steering

components. Steering should move

freely through entire range of travel

without binding.

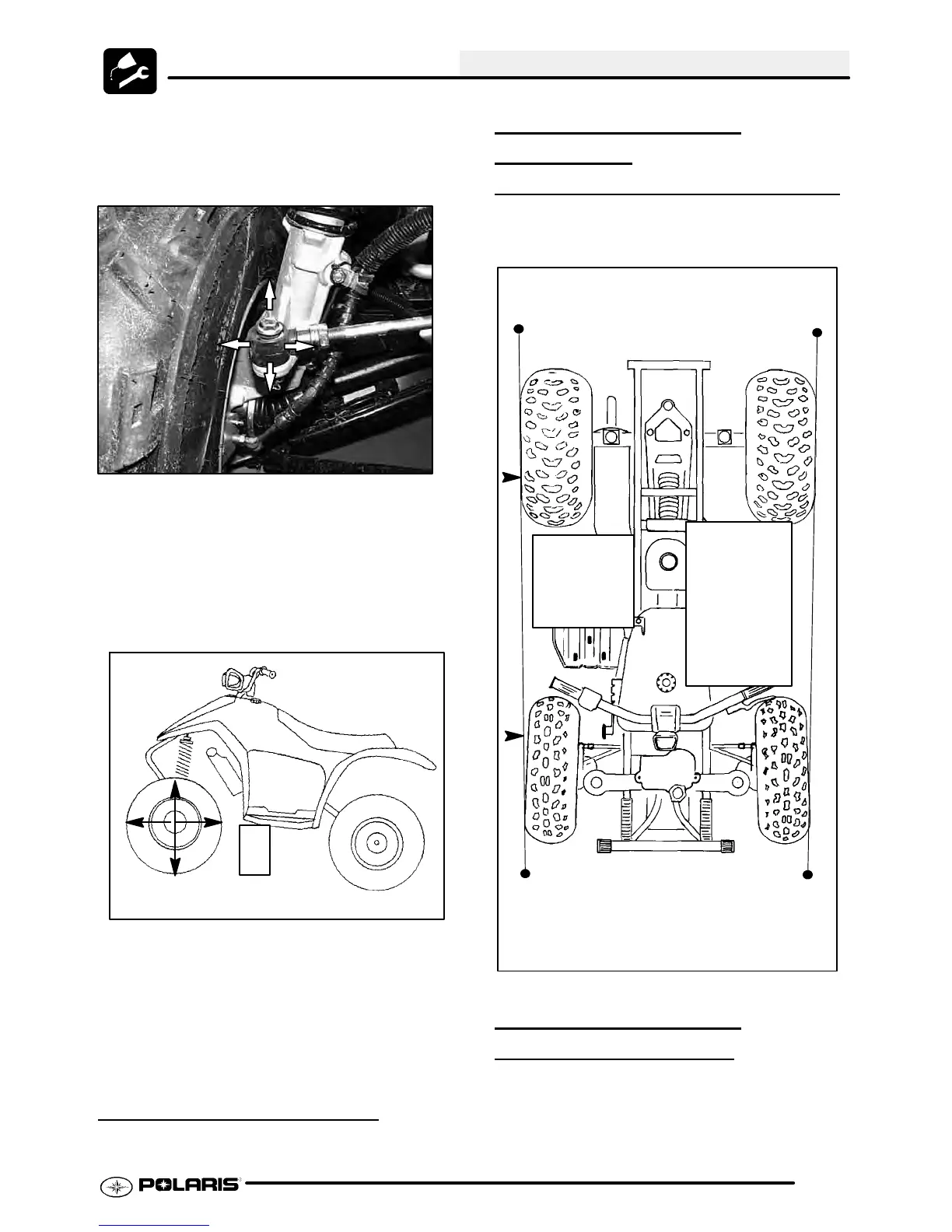

G Elevatefrontend of machine so front

wheels are off theground. Check for

any looseness in front hub / wheel

assembly by grasping the tire firmly

at top and bottom first, and then at

frontandrear. T rytomovethewheel

and hub by pushing inward and

pulling outward.

Check for Loose Wheel or Hub

G If abnormal movement is detected,

inspect the hub and wheel assembly

to determine the cause (loose wheel

nuts, loose front hub nut (4x4).

G Refer to the Body/Steering or Final

Drive chapter for more information.

CAMBER AND CASTER

The camber and caster are non-adjustable.

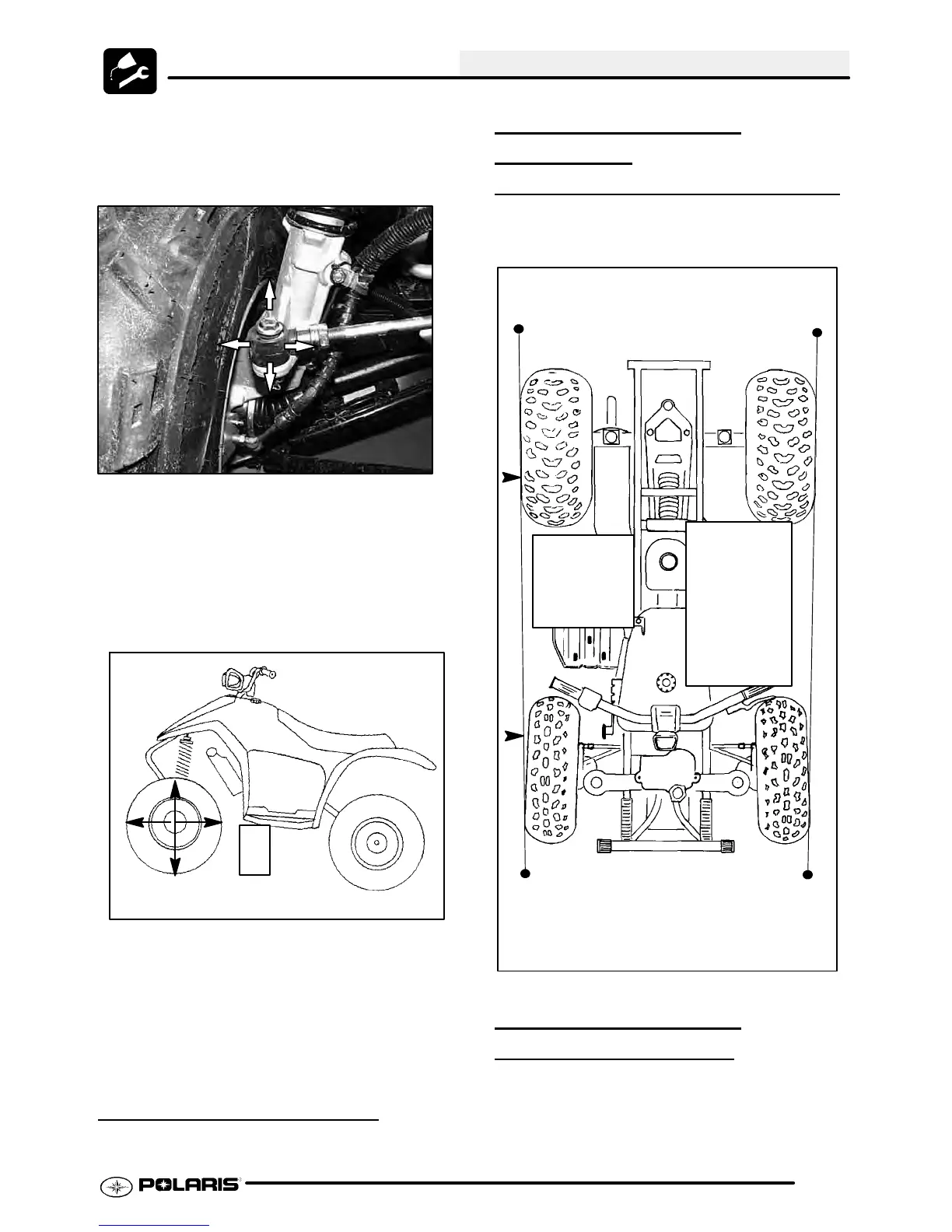

WHEEL ALIGNMENT

METHOD 1:

STRAIGHTEDGE OR STRING

Be sure to keep handlebars centered. See notes

below.

NOTE: String should just touch side sur-

face of rear tire on each side of machine.

NOTE: The steering post arm “frog” can be

used as an indicator of whether the handle-

bars are straight. The frog should always

point straight back from the steering post.

Rear rim

measure-

ment should

be 1/16″ to

1/8″ (.2to.3

cm) more

than front rim

measure-

ment.

Measure

from string

to rim at

front and

rear of rim.

WHEEL ALIGNMENT

METHOD 2:

CHALK

1. Place machine on a smooth level surface.

2. Set handlebars in a straight ahead position and

secure handlebars in this position. NOTE: The

steeringarm “frog” can be used as an indicator of

whether the handlebars are straight. The frog

Loading...

Loading...