ENGINE

3.31

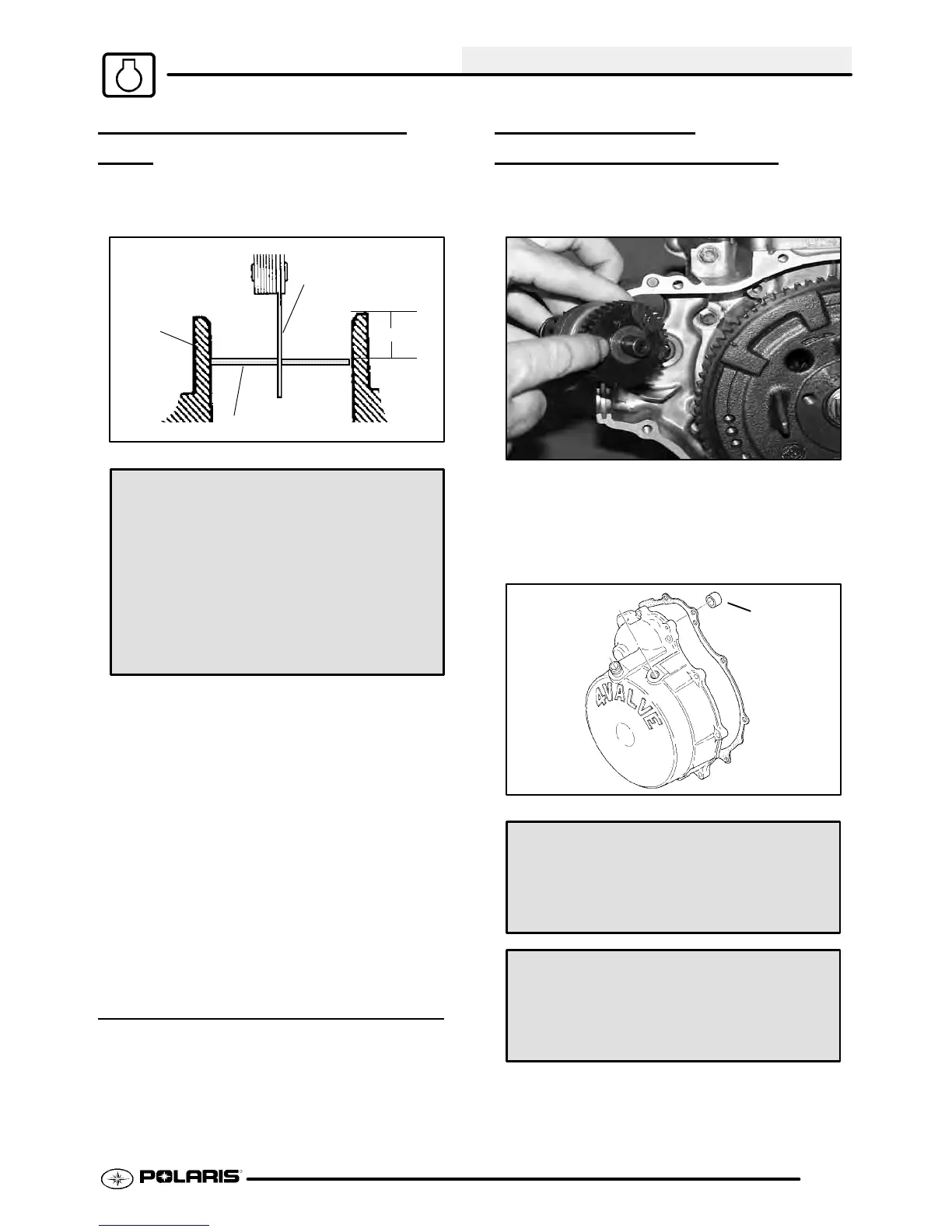

PISTON RING INSTALLED

GAP

1. Placeeach pistonringinsidecylinderusingpiston

to push ringsquarely into place as shown at right.

25-50mm

Cylinder

Piston Ring

Feeler Gauge

Piston Ring Installed Gap

Top Ring

Std: .0079-.0138I (.20- .36 mm)

Limit: .039I (1.0 mm)

Second Ring

Std: .0079-.0138I (.20- .36 mm)

Limit: .039I (1.0 mm)

Oil Ring

Std: .0079-.0276I (.20- .70 mm)

Limit: .059I (1.5 mm)

2. Measure installed gap witha feelergauge at both

the top and bottom of the cylinder. NOTE: A

difference in end gap indicates cylinder taper.

The cylinder should be measured for excessive

taper and out of round.

3. Ifthebottominstalledgapmeasurementexceeds

the service limit, replace the rings. If ring gap is

below specified limit, file ring ends until gap is

within specified range.

NOTE: Always check piston ring installed gap after

re-boring a cylinder or when installing new rings. A

re-bored cylinder should always be scrubbed

thoroughly with hot soapy water, rinsed, and dried

completely. Wipe cylinder bore with an oil rag

immediately to remove residue and prevent rust.

CRANKCASE DISASSEMBLY

NOTE: Therecoilstarter,startermotor, starterdrive,

flywheel, stator , cam chain and sprockets can be

serviced with the engine in the frame.

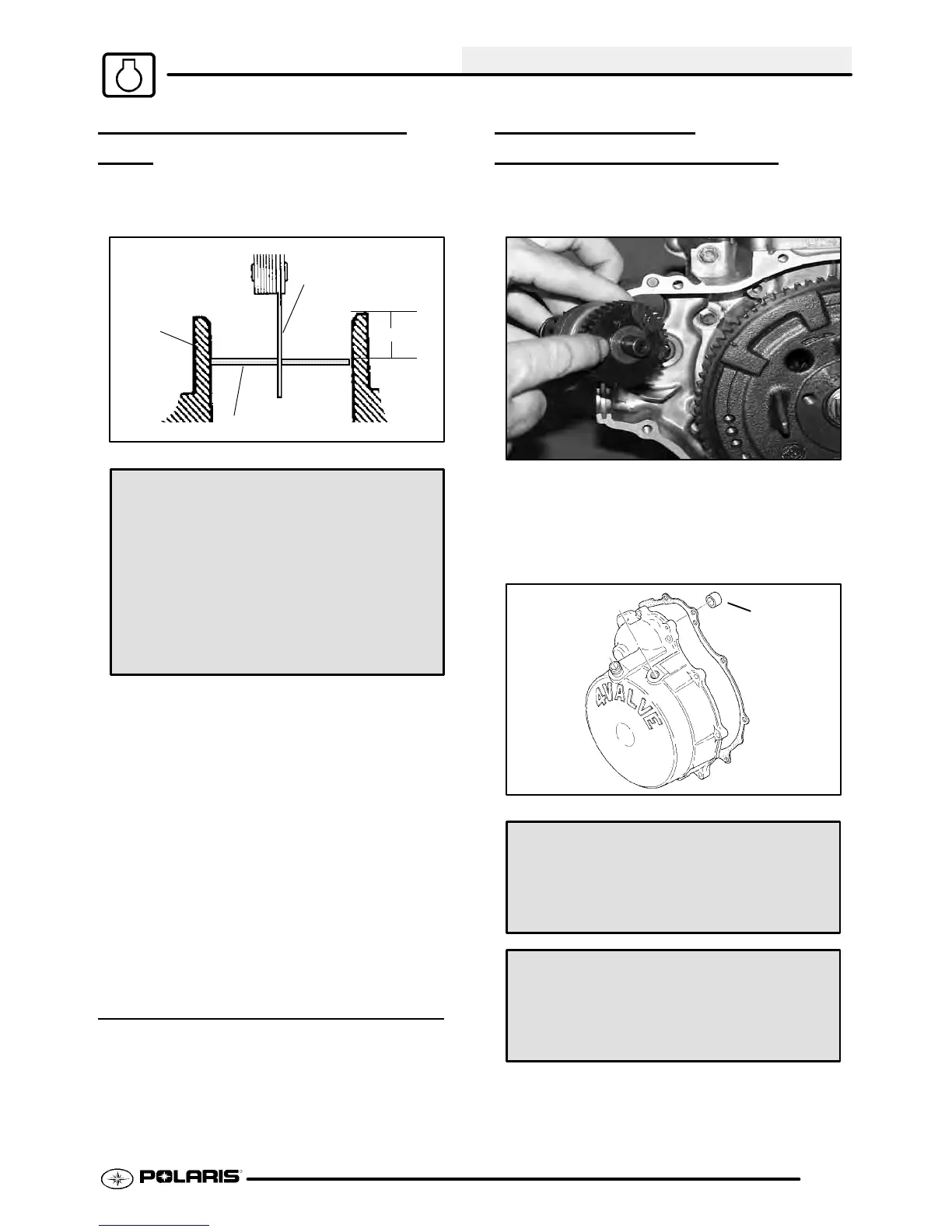

STARTER DRIVE

REMOV

AL/INSPECTION

1. Remove recoil housing bolts and remove

housing.

2. Remove starter drive assembly. Note the thrust

washer located at the rear of the drive

mechanism.

3. Inspect thethrustwasherforwearordamageand

replace if necessary.

A

Std. Bushing ID:

.4735″- .4740″ (11.11-12.04 mm)

Std. Shaft OD:

.470″- .472″ (11.93-11.99 mm)

Starter Drive Bushing Clearance:

Std: .0015″-.004″ (.038-.102 mm)

Service Limit:

.008″ (.203 mm)

4. Measure the ODof thestarter driveshaft on both

ends and record.

Loading...

Loading...