ENGINE

3.40

COUNTER BALANCER

SHAFT END PLAY ADJUST

.

Step 2

1. Make sure all bearings are firmly seated in the

crankcase.

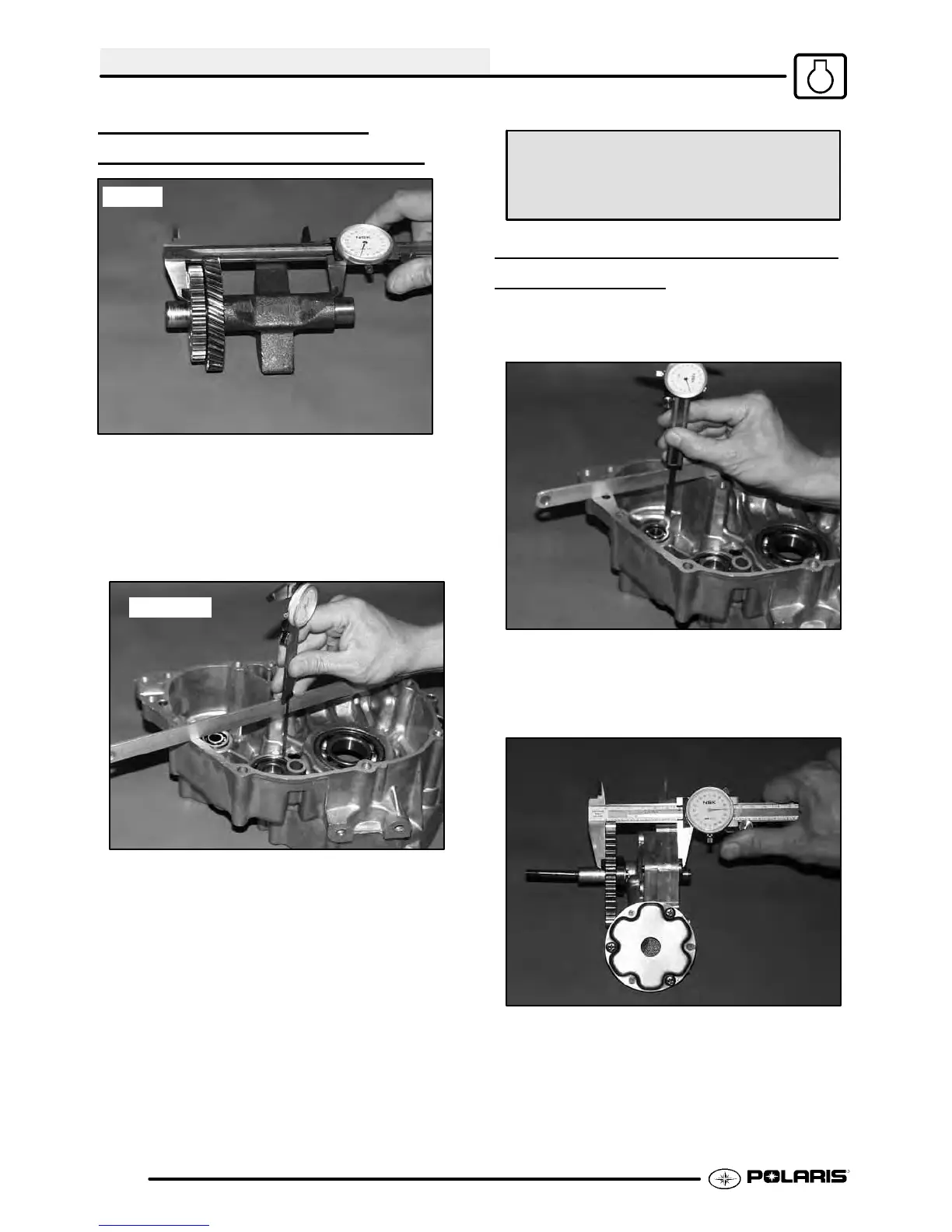

2. Measure the width of the counter balancer shaft

at the bearing seats with a dial caliper or

micrometer, and record reading.

Step3/4

3. Measure the distance from the Mag crankcase

matingsurfacetothebalanceshaft bearingusing

a dial caliper and a straight edge. Subtract the

thickness of the straightedge and record.

4. Measure the distance from the PTO crankcase

mating surface to the bearing using the same

method outlined in Step 1, 2, and-3.

5. Add the readings obtained in Step 3 and Step 4.

6. Subtract the counter balancer shaft width

measured in Step 2 from the figure obtained in Step

5.

7. Subtract the thickness of the existing shim from

theresultofStep6todetermineif a differentshim

isneeded. Theresultmustbewithinthespecified

range listed at below .

Counter Balancer Shaft End Play:

.008″- .016″ (.02-.04 cm)

OIL PUMP SHAFT END PLAY

ADJUSTMENT

1. Makesurethepumpshaftbearingisfirmlyseated

in the Magneto side crankcase.

2. Measure the distance from the magneto

crankcase mating surface to the bearing using a

dial caliper and a straight edge. Subtract the

thickness of the straightedge and record.

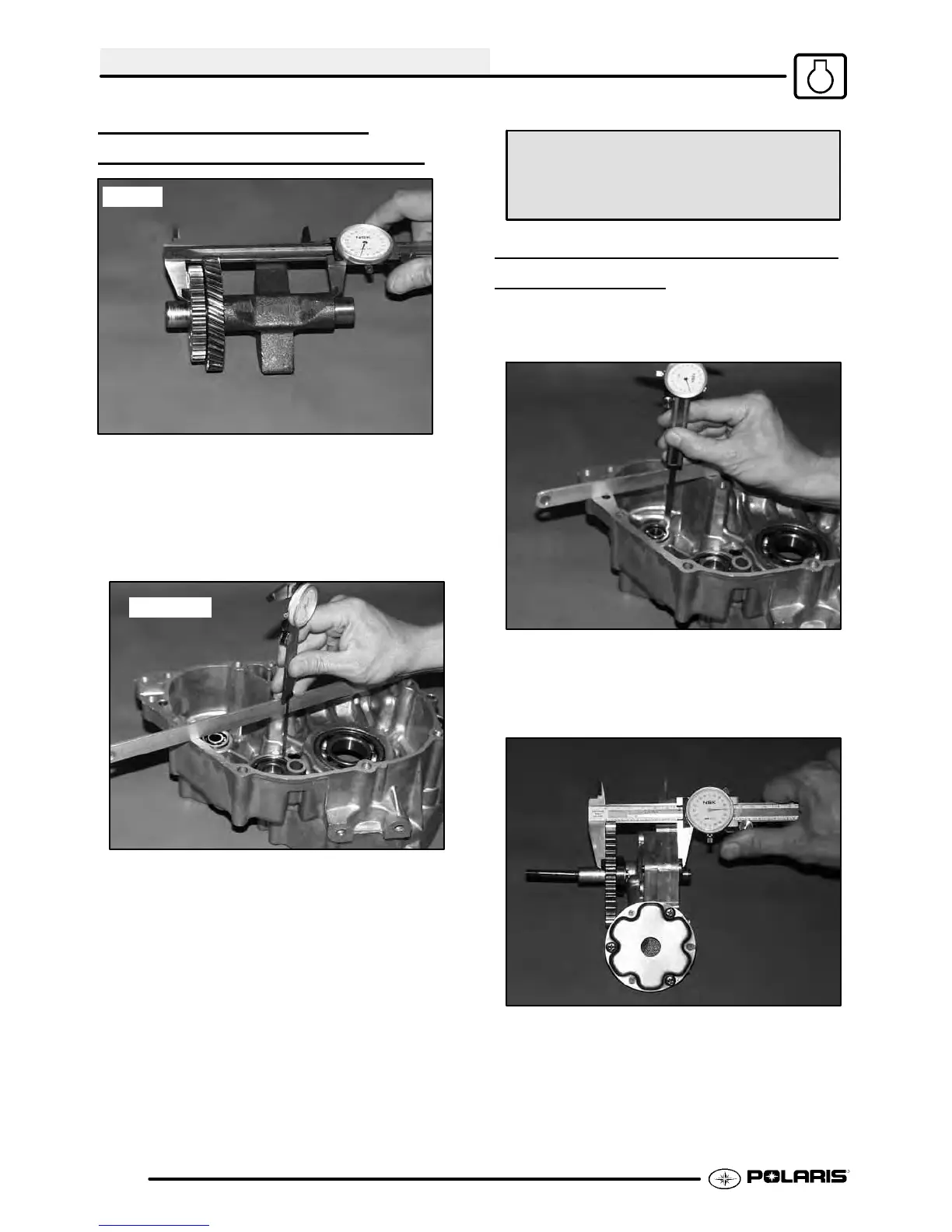

3. Install the gear on the oil pump and measure the

width of the pump and gear . Subtract this

measurementfromthemeasurementrecordedin

Step 2.

4. Subtract the thickness of the existing shim from

theresultofStep3todetermineif a differentshim

is needed. See Shaft End Play Spec. next page.

Loading...

Loading...