FINAL DRIVE

7.8

6. Without removing the garter spring, inspect the

coils for consistency. If coils are distorted or

uneven, cut the old spring with a side cutter to

remove it, and replace it.

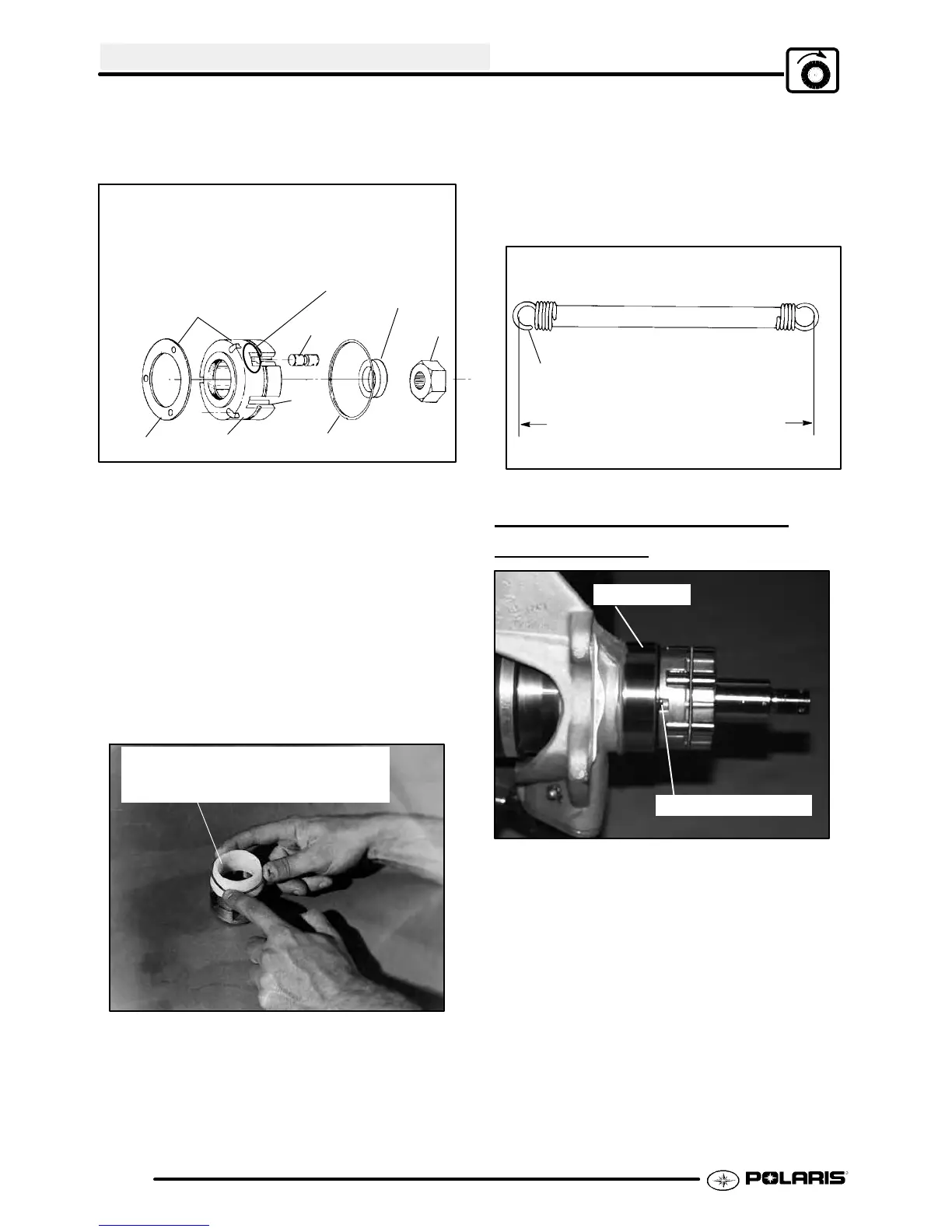

12

3

5

4

A

Engage tabs in the slots

1.Armature Plate NOTE: Armature plate is

positioned with tabs in round holes of cage.

2.Roller Cage

3.Roller

4.Garter Spring

5.Cam

Spacer

Inspect for cracks

7. If garter spring replacement is necessary, it is

very important that the correct installation

procedure and special tool be used. Hold rollers

in place on roller cage with a light film of grease.

Gentlyand evenly rollthespringdown theHilliard

Clutch Garter Spring Installation Tool (PN

2870888) and into the groove of the rollers and

cage. WARNING: If this procedure is not

followed the spring will be over stressed and lose

its tension. Springs with incorrect tension may

allow rollers to move outward at high vehicle

speeds. If the rollers move outward, the front

hub(s) will engage and cause vehicle instability,

which could result in serious injury or death.

Must use Hilliard Clutch Garter

Spring Installation Tool

(PN 2870888)

W ARNING: Be sure to use correct garter spring.

Thesesprings areverysimilarinappearanceto those

usedonearlier models. Iftheold, lighterspringswere

installed on a machine requiring the heavier spring,

the front wheels may engage at high speed, possibly

resulting in serious injury or death. Check springs

before installation. Always verify the correct

replacement spring part number by referring to

the appropriate parts manual.

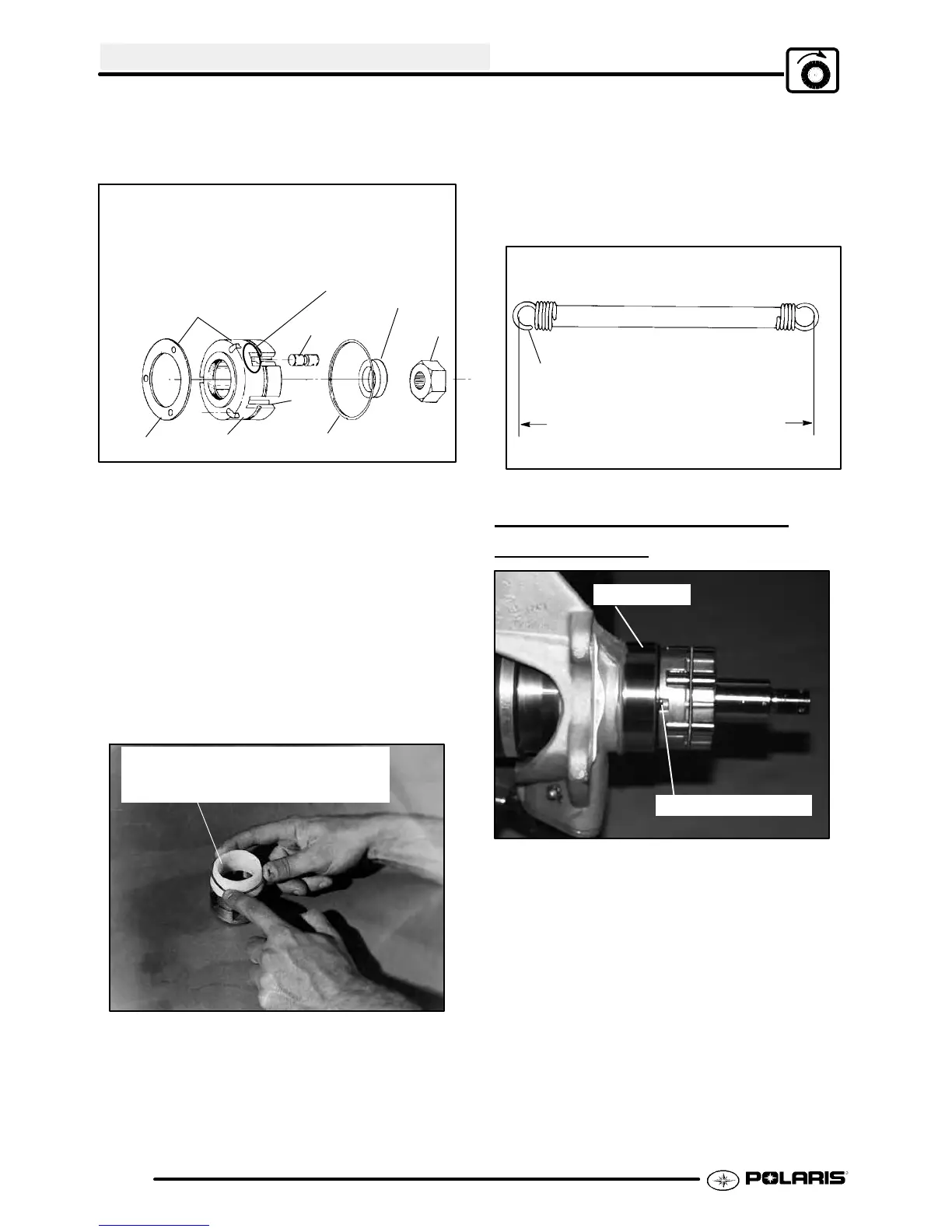

8. Current electro-mechanical spring, (PN

3250032); wire diameter .018″ (.46 mm); spring

free length end to end inside hooks 6.968″ (177

mm).

Measure wire diameter

Measure free length to inside of

loops as shown

AWD ARMATURE PLATE

INSPECTION

Armature Plate Tabs

Seal Sleeve

1. As the armature plate is engaged, it should

contact the outer magnet pole (seal sleeve) and

the inner magnet pole. Also, the armature plate

must be flat when placed on a flat surface. Bent

armature plates should be replaced.

NOTE: Itis notunusualtoseeadouble wearring

on the armature plate; however, the wear rings

should be even.

2. Install the roller clutch (Hilliard Clutch) assembly

and be sure the armature plate (A) is positioned

properly. Also,when installingthe hub assembly,

be sure the armature plate tabs remain engaged

with the roller clutch cage.

CAUTION: After the hub is installed, the slightest

movement outward with the hub may cause the

armatureplatetabstodisengagefromtherollerclutch

Loading...

Loading...