FINAL DRIVE

7.7

MAGNETIC COIL REMOVAL

1. Remove the front drive axle as described later in

this chapter .

2. Remove the seal sleeve from the strut casting

using a drift punch and hammer , tapping evenly

on each side until the sleeve slides off.

3. Remove the existing coil and clean the coil wire

channel, coil mount area, and the seal sleeve

mounting area of all silicone and foreign matter.

4. Disconnect the coil wires at the connector or

terminal board.

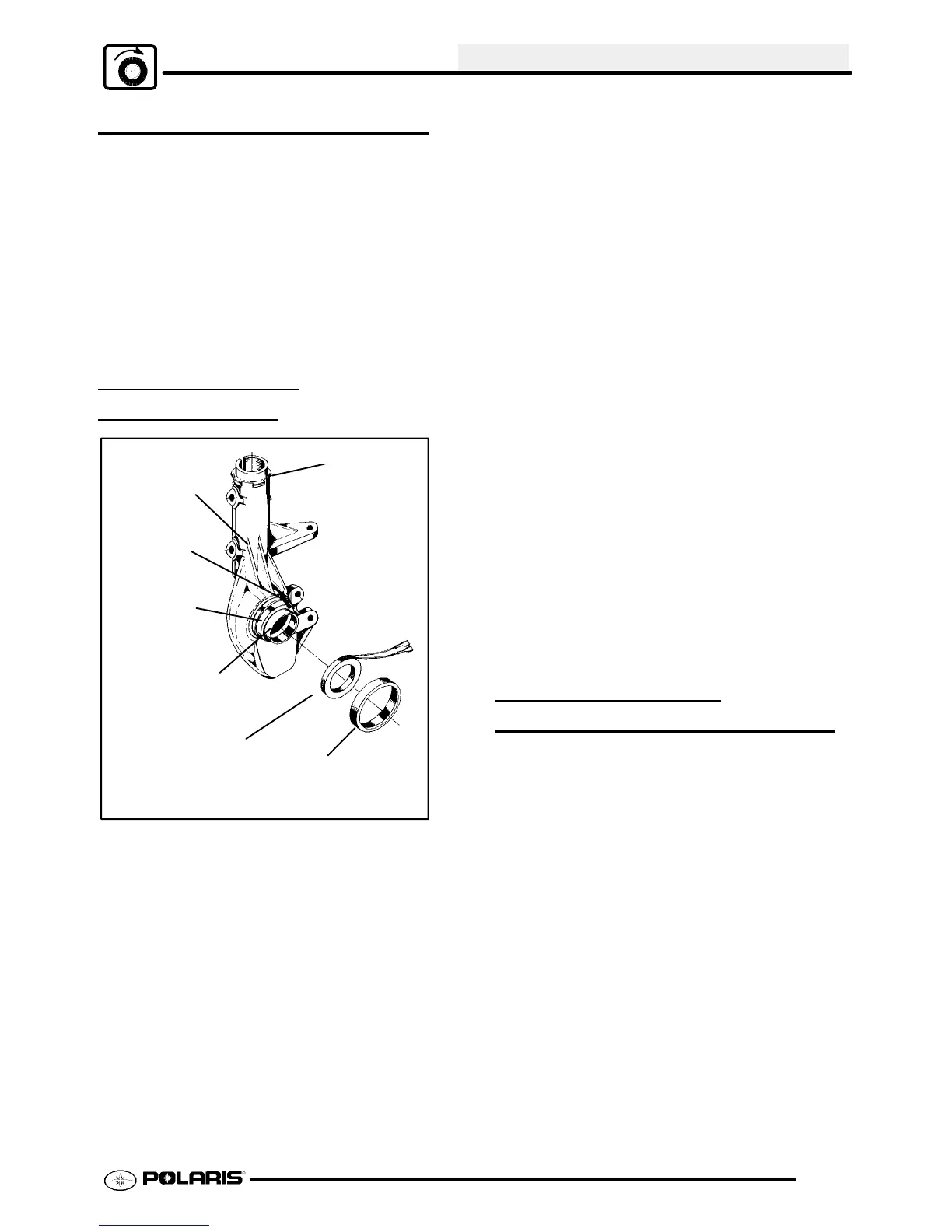

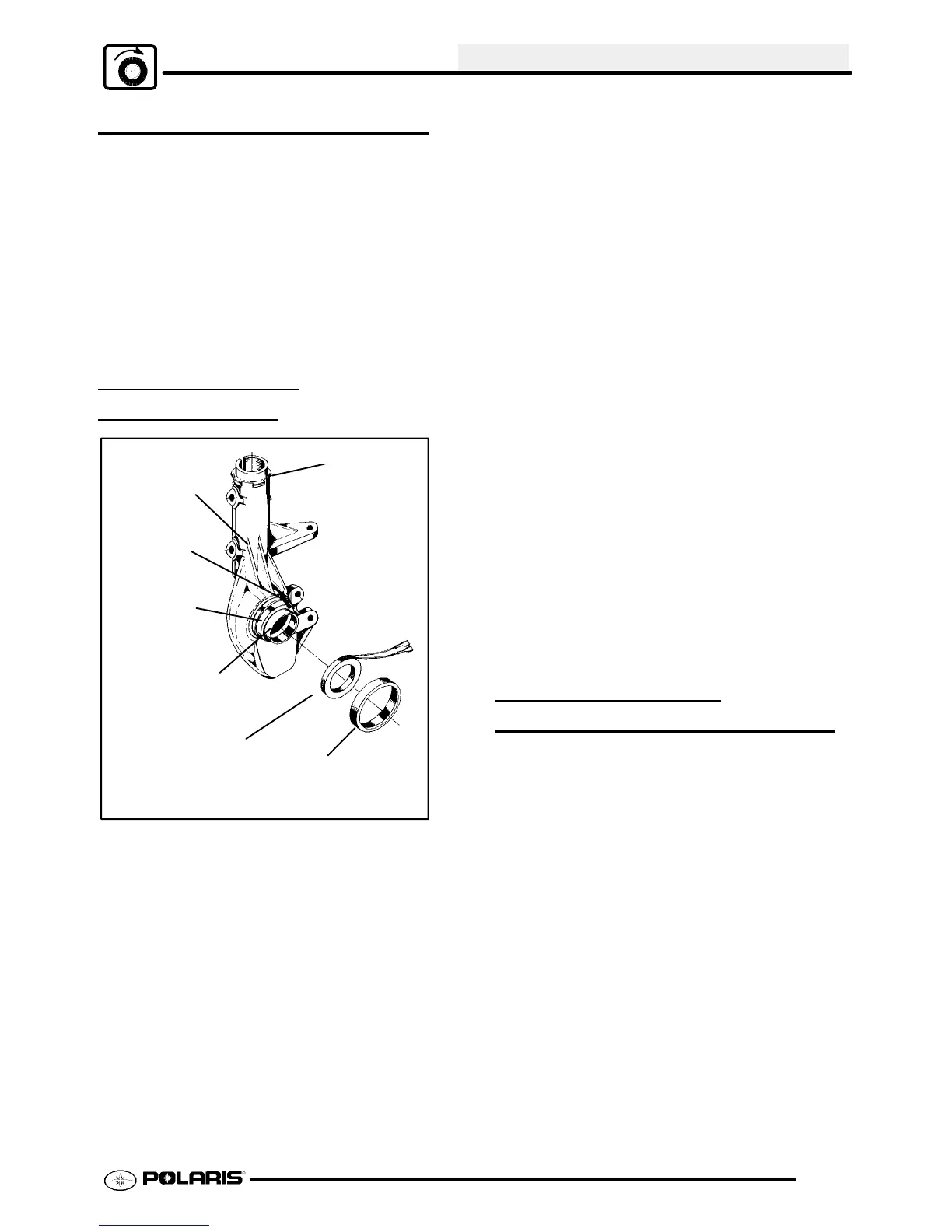

MAGNETIC COIL

INSTALLA

TION

Brake Line

Clip Location

Strut Ribs

Coil Wire

Channel

Seal

Sleeve

Mounting

Area

Coil Mounting

Surface

(Inner Magnet

Pole)

(Fixed)

Electromagnet Coil

Seal Sleeve (Outer Magnet Pole)

(Adjustable) Must use Seal Sleeve

Installation Tool Kit (PN 2871199)

1. Apply1/4I(.6 cm) bead of silicone in the coil wire

channel.

2. Install thecoil tothe coil mount surface andpress

the coil wires into the silicone in the coil wire

channel.

3. Apply 1/4I (.6 cm) bead of Loctitet Ultra Blue

silicone around the seal sleeve mounting area.

NOTE: This includes applying silicone over the

coilleadwires again. Always allow12hours’cure

time for silicone.

4. Press on the seal sleeve until even with the inner

pole. See Page 7.17 for additional information.

Once the seal sleeve is properly positioned, a

1/16I (.16 cm) bead of silicone should remain

around the inner edge. Clean off all excess

silicone. The seal sleeve area must be free of

silicone or the hub seal may leak.

NOTE:

S Always install a new seal sleeve

when replacing the coil. Use Seal

Sleeve Installation Tool Kit (PN

2871199).

S It may be necessary to apply more

silicone (or an equivalent fast drying

glue) to the wire channel area to

properly secure and protect the coil

wires.

S Apply 401 Loctitet to the inside of

the strut ribs and press the foam

block to containthe coil wires. Make

sure thefoam block is bonded well to

protect the coil wires.

NOTE: Coil wires must be contained in the brakeline

clipon thebacksideof theupper strutcastingandthe

wires must be snug against the casting.

5. Route the wires smoothly and away from any

moving parts and secure in place with tie straps.

6. Assemble front axle and connect hub wires.

HILLIARD CLUTCH

DISASSEMBL

Y/INSPECTION

1. Remove front hub.

2. Remove Hilliard clutch assembly.

3. Disassemble the roller clutch and thoroughly

clean all parts. CAUTION: Do not remove the

garter spring. If the spring is removed, it will

become over stressed and will require

replacement.

4. Inspect rollcage sliding surface (A). Thissurface

must be clean and free of nicks, burrs or

scratches. Inspect roller cage (2) carefully for

cracks.

5. Inspect rollers (3). The rollers must slide up and

down freely within the roller cage sliding surfaces

A.

Loading...

Loading...