BRAKES

9.20

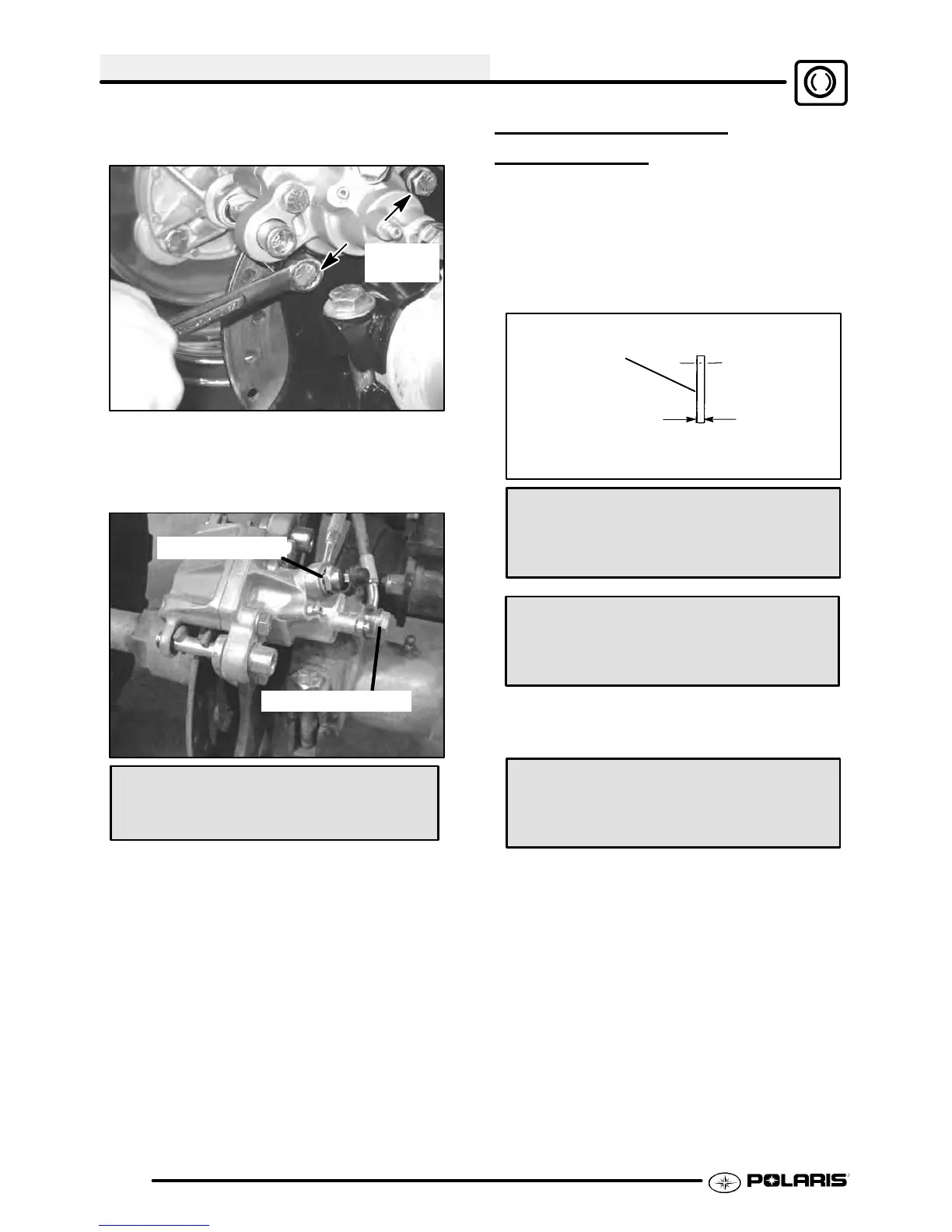

4. Install caliper and tighten mounting bolts, then

torque mounting bolts to 18 ft.lbs (25 Nm).

18 ft.lb s .

(25 Nm)

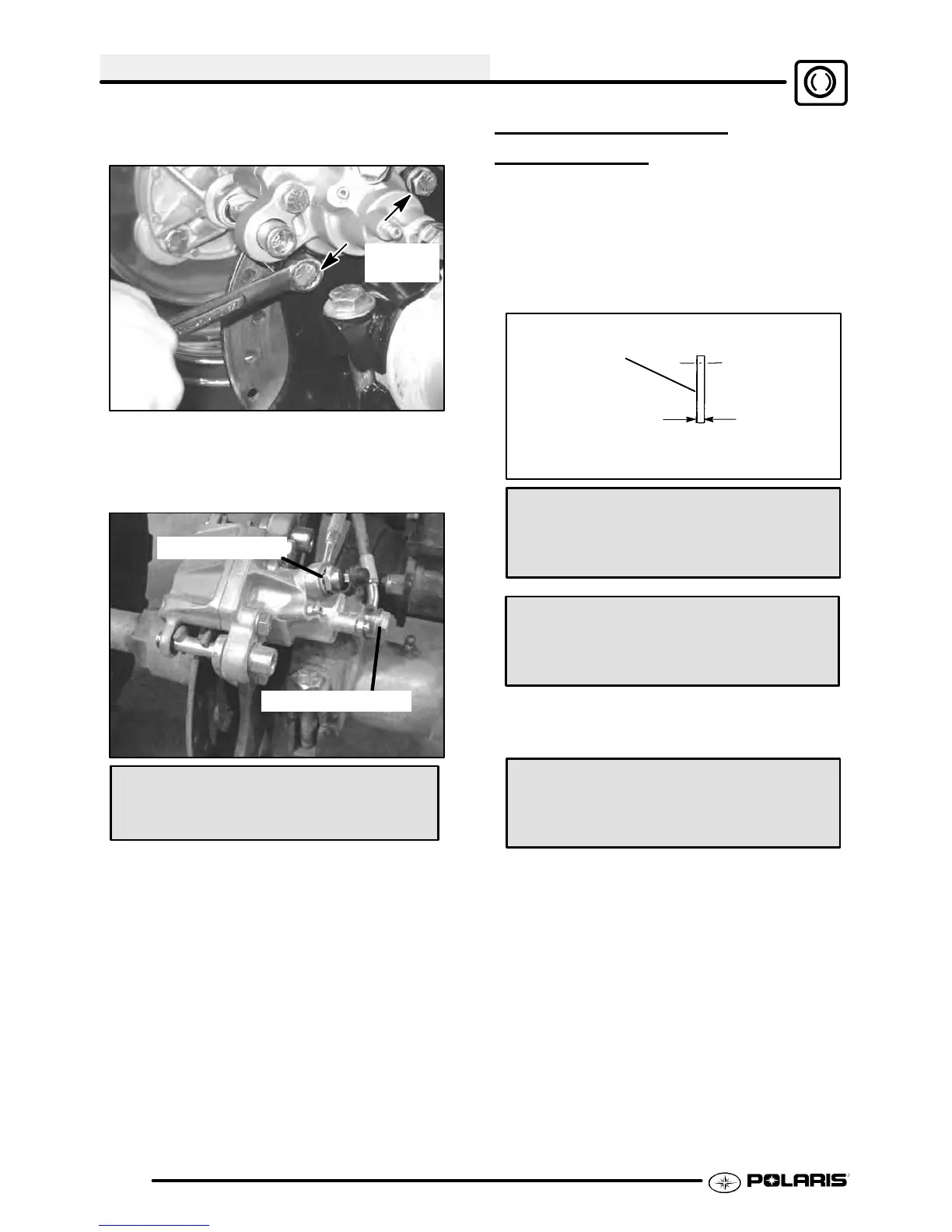

5. Install brake line and tighten securely with a line

wrench. Torque the brake lines to 15 ft.lbs (21

Nm).

Hand Brake Line

Auxiliary Brake Line

Brake Line Torque

Banjo Brake Line: 15 ft. lbs. (21 Nm)

6. Follow bleeding procedure outlined in this

chapter.

7. Field test unit for proper braking action before

putting into service. Inspect for fluid leaks and

firm brakes. Make surethe brake is not dragging

when lever is released. If the brake drags,

re-check assembly and installation.

REAR BRAKE DISC

INSPECTION

1. Visually inspect disc for scoring, scratches, or

gouges. Replace the disc if any deep scratches

are evident.

2.Usea0-1″ micrometer and measure disc

thicknessat8differentpoints aroundperimeterof

disc. Replace disc if worn beyond service limit.

Measure

Thickness

Rear Brake

Disc

Brake Disc Thickness

Service Limit .140″ (3.55 mm)

New .150-.165″ (3.81-4.19 mm)

Brake Disc Thickness Variance

Service Limit .002″ (.051 mm)

difference between measurements

3. Mount dial indicator and measure disc runout.

Replacethe discif runout exceeds specifications.

Brake Disc Runout

Service Limit .010″ (.254 mm)

Loading...

Loading...