5.20

Engine and Cooling Systems

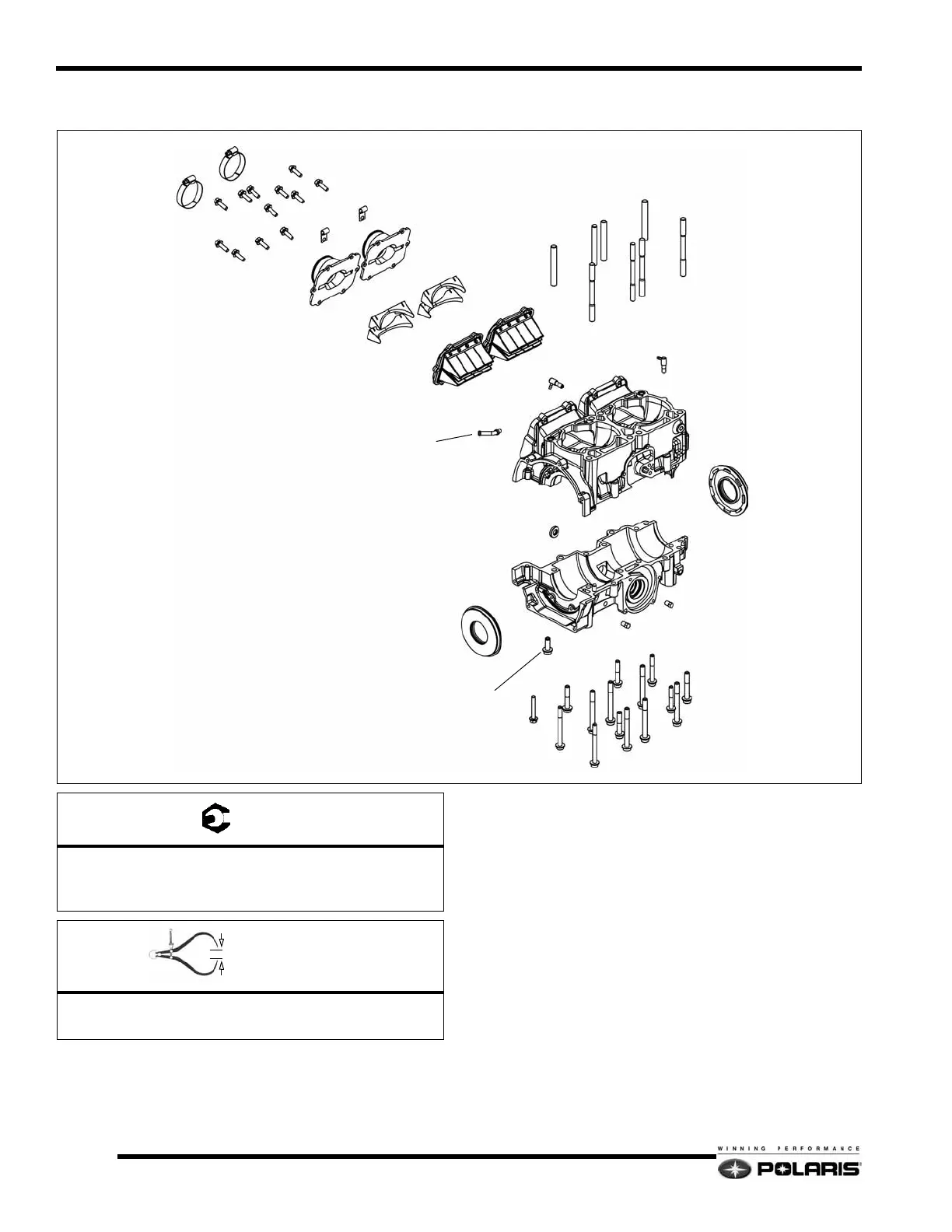

600 HO Carbureted Crankcase

Disassembly / Assembly Process

1. Remove the engine from the engine compartment.

2. Follow the process for removing the cylinder head,

cylinders, pistons, flywheel / recoil housing, and the water

/ oil pump.

3. Remove the intake boots, and reed assemblies. Discard any

seals or gaskets.

4. Remove the crankcase fasteners then carefully pry apart the

crankcase halves. Discard the PTO and MAG crankshaft

seals.

5. Clean the two crankcase mating surfaces with carburetor

cleaner and a gasket remover. Flush out the crankcase.

6. Reinstall the crankshaft back into the lower crankcase using

two new crankcase seals.

7. Apply a thin bead of Three Bond 1215 to the lower

crankcase mating surface. Install the upper crankcase.

8. Loosely install the crankcase fasteners, then torque to the

specifications at the beginning of the chapter. Use the

correct torque sequence when tightening the screws.

INTAKE BOOTS

REED STUFFERS

REED ASSEMBLIES

IMPULSE FITTING

OIL INJECTION CHECK VALVES

CRANKCASE

WATERPUMP BUSHING SCREW

DRAIN PLUGS

CYLINDER STUDS

A

B,C

= T

A = 9 Ft.Lbs. (12 Nm)

B = (M8) - 22 Ft.Lbs. (30 Nm) - Apply Loctite 242

C = (M6) - 9 Ft.Lbs. (12 Nm) - Apply Loctite 242

= In. / mm.

Long Studs Height (Exhaust side) = 3.66" (93mm)

Small Stud Height (Intake side) = 2.16

" (55mm)

Loading...

Loading...