3.7

Maintenance

3

ENGINE MAINTENANCE

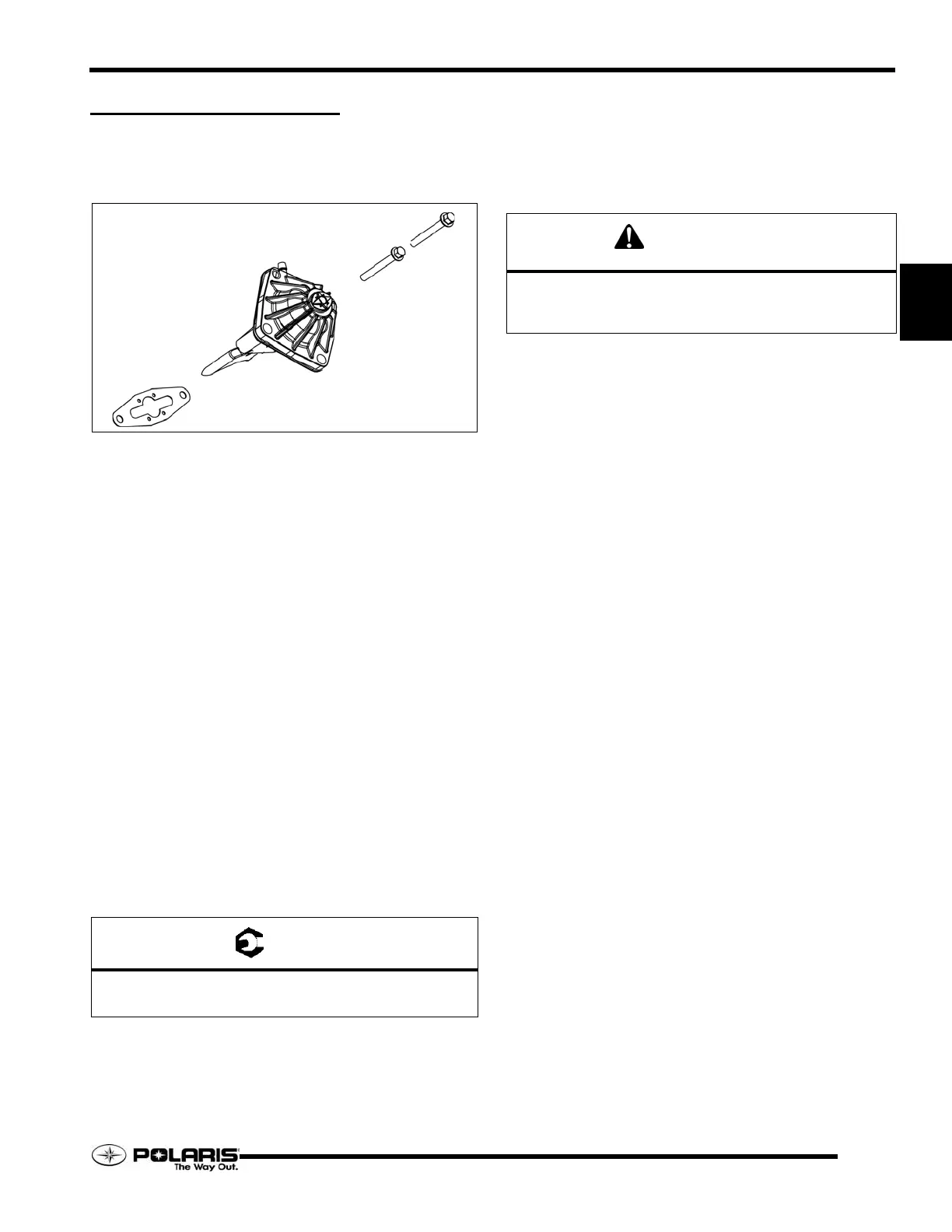

Exhaust Valve Cleaning

The exhaust valve guillotines must be cleaned to ensure

maximum engine performance and throttle response.

1. Remove the vent hose from the EV base fitting.

2. Remove the two fasteners that secure the valve assembly

to the cylinder, but not the two screws that secure the cover

to the EV base.

3. Carefully extract the guillotine out of the cylinder. Discard

the gasket.

4. Using a clean rag or shop towel, remove the oil residue from

the cylinder, guillotine, and EV base.

5. Inspect the guillotine for signs of damage. Replace

guillotine if damage is found, and inspect the cylinder and

piston for damage.

6. Clean the guillotine with brake cleaner and a piece of fine

steel wool. Clean only to remove hardened carbon deposits.

7. Once clean, rinse blade with mild detergent and water. Dry

completely.

8. Install a new gasket, then reinstall the EV assembly. Apply

Loctite 242 to the fastener threads, then torque to

specification.

9. Reconnect the vent hose.

NOTE: To obtain maximum exhaust valve

performance, Polaris recommends using Polaris

VES Gold Synthetic Two-Stroke engine oil.

Never mix different brands of engine oil.

Surge Tank

Keep the level of the coolant inside the surge tank at the FULL

COLD level mark when the coolant is at room temperature.

Always add coolant when the cooling system is COLD.

Recommended Coolant

Use Polaris Premium 60 / 40 pre-mix antifreeze. This premium

antifreeze is rated for temperatures down to -62°F (-52°C).

Cooling System Bleeding

1. Allow the cooling system to cool completely.

2. Verify the coolant level in the surge tank is at the COLD

mark. Fill the surge tank if required. Loosely install the

pressure cap.

3. Open the thermostat housing bleed screw. Wrap a clean

shop towel around the housing to absorb any coolant that

may flow out of the bleed screw.

4. Elevate the front of the machine slightly.

5. Apply the parking brake and start the engine.

6. Allow the engine idle time to stabilize.

7. Immediately add coolant to the surge tank if the coolant

level dropped significantly after the engine started. Watch

the level and add more coolant until the level stops

dropping.

NOTE: Squeeze the coolant hoses to purge air from

the cooling system.

8. Secure the pressure cap and bleed screw after the

thermostat begins to open and coolant begins to flow out

of the bleed screw.

9. Verify the tunnel coolers begin to warm up as the engine

continues to run.

10. To remove air from the tunnel cooling system, the vehicle

should be pivoted upwards in four directions (nose up, left

side up, rear bumper up, and right side up) to move any air

pockets in the system to the surge tank.

= T

Exhaust Valve Housing Fasteners

12 Ft.Lbs. (16 Nm) - Apply Loctite 242

GASKET

EV ASSEMBLY

FASTENERS

CAUTION

Never remove the surge tank pressure cap when the cooling

system is warm. Severe burns to skin may occur from escaping

coolant or steam.

Loading...

Loading...