4.10

Fuel Systems

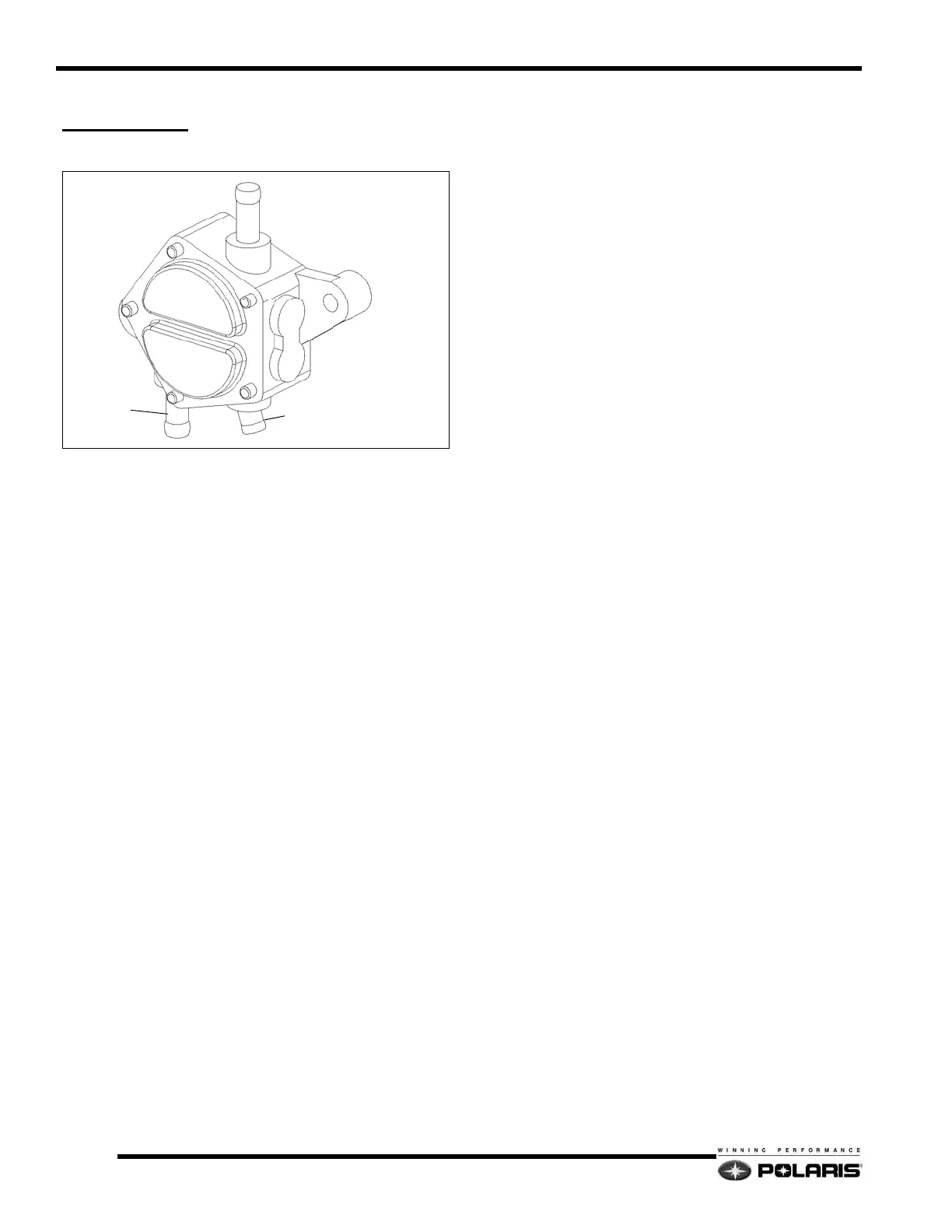

FUEL PUMP

Fuel Pump Overview

The impulse-powered fuel pump on carbureted engines works

by using the positive and negative pressure pulses generated by

the movement of the pistons inside the engine crankcase.

When the MAG piston is on the upward stroke, negative

(vacuum) pressure pulse is applied to the fuel pump. This action

draws fuel into the pump from the fuel tank.

When the MAG piston is on the downward stroke, a positive

pressure pulse is applied to the fuel pump. This action forces

fuel from the intake-side of the pump to the supply-side, then to

the carburetors.

A series of check valves prevents fuel from being drawn out of

the carburetors on the vacuum stroke or forced back into the fuel

tank during the pressure stroke.

Maintenance

The impulse operated-powered fuel pump does not require any

specific scheduled maintenance. However, the following

procedures should be observed:

•Operation

The pump may be checked for operation by removing the fuel

supply line from the carburetor and placing it into a container.

With the engine idling at approximately 2000 RPM, a steady

flow of fuel should be visible.

• Cleaning

The impulse line must be disassembled and cleaned of foreign

material in the event of piston or other internal engine part

failures which produce fragments.

• Inspection

Disconnect impulse line from pump. Connect a Mity Vac to

impulse fitting (or line) and apply 4-6 PSI pressure. Diaphragm

should hold pressure indefinitely.

FUEL IN (FROM TANK)

IMPULSE HOSE FITTING

(ALWAYS ON BACK OF PUMP)

FUEL OUT

Loading...

Loading...