1.4 DRUM POTENTIAL CONTROL

The characteristics of the drum vary with the temperature around the drum,

and they change as the drum gets older. To take account of these and other

related factors, this machine has the following three drum potential control

routines.

• V

R

pattern correction

• V

L

pattern correction

• T/H correction

1.4.1 V

R

Pattern Correction

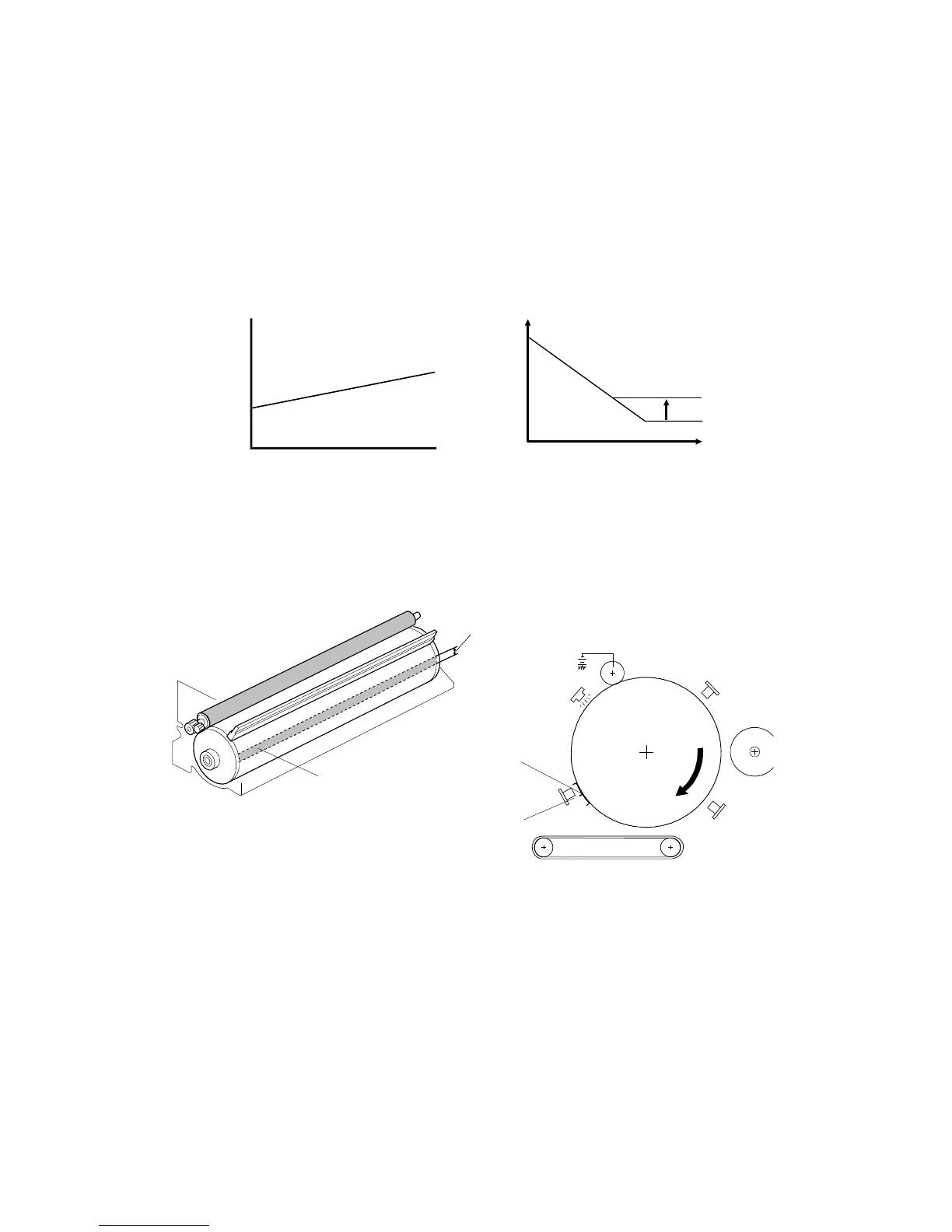

As the drum ages, the drum residual voltage gradually increases due to

electrical fatigue (see the upper left chart). In other words, as the drum gets

older, light does not discharge it as much (see the upper right chart). This

may cause dirty background on copies. V

R

pattern detection every 1,000

copies using the ID sensor avoids this problem.

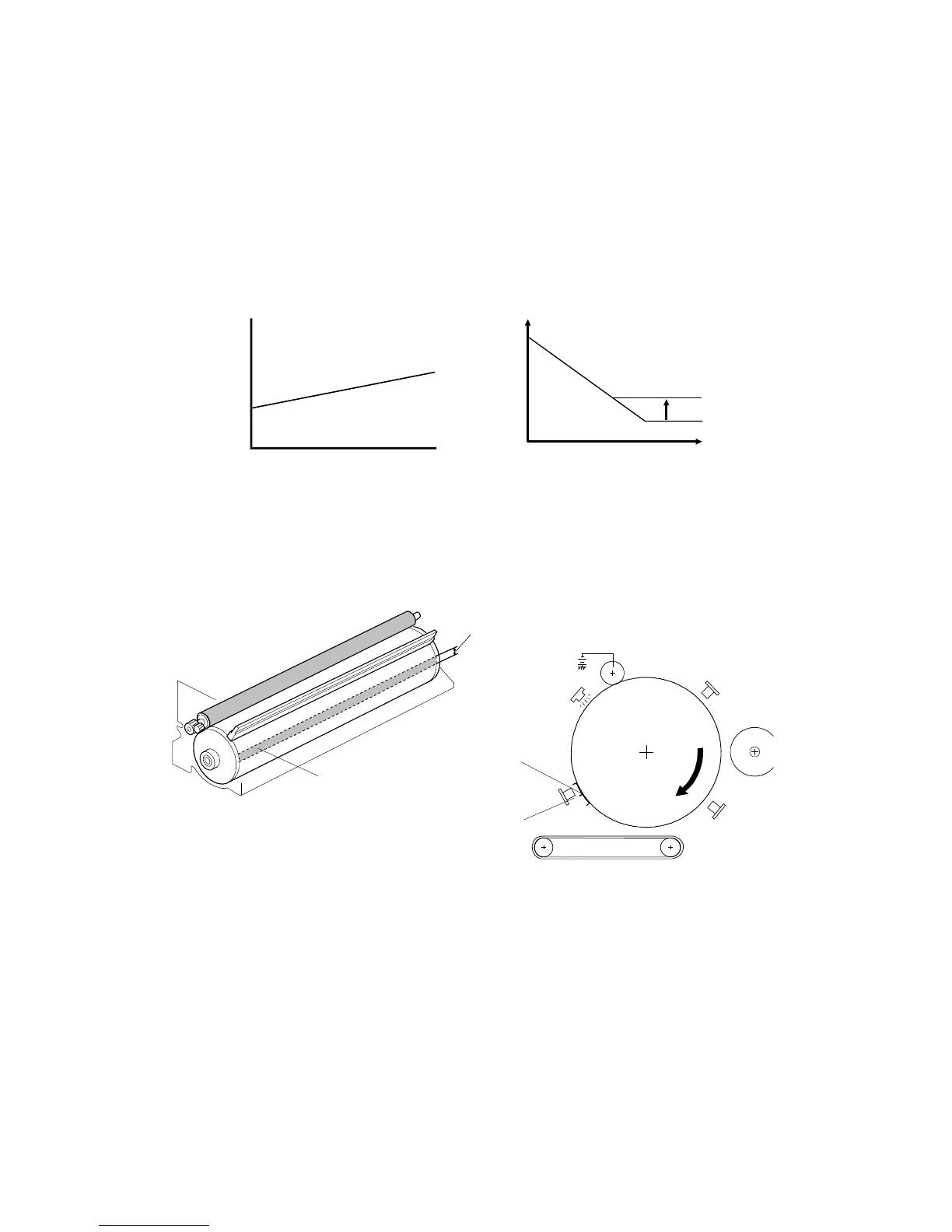

Every time V

R

pattern detection is done, a strip across the drum is charged

using zero development bias and the standard charge on the drum charge

roller that is used for copying (with all corrections included). At the same

time, all the blocks of the erase lamp turn on to illuminate this charged area

of the drum.

Copy volume

Drum

residual

voltage

(V)

Light intensity

Drum

potential

(V)

Old Drum

New Drum

V

R

Pattern

0V Bias

ID Sensor

V

RP

A156/A160/A162 2-18 STM

Loading...

Loading...