1.3 IMAGE DENSITY CONTROL

1.3.1 Overview

The machine controls the toner supply mechanism using the toner density

sensor (TD sensor) and the image density sensor (ID sensor).

Readings from the TD sensor are used to keep the toner concentration in the

developer at a constant level. However, the image on the OPC drum varies

due to the variation in toner chargeability, which is influenced by the

environment, even if the toner concentration is constant. Because of this,

readings from the ID sensor are used to change the toner concentration to

keep the image density on the OPC drum constant.

1.3.2 V

SP

and V

SG

Detection

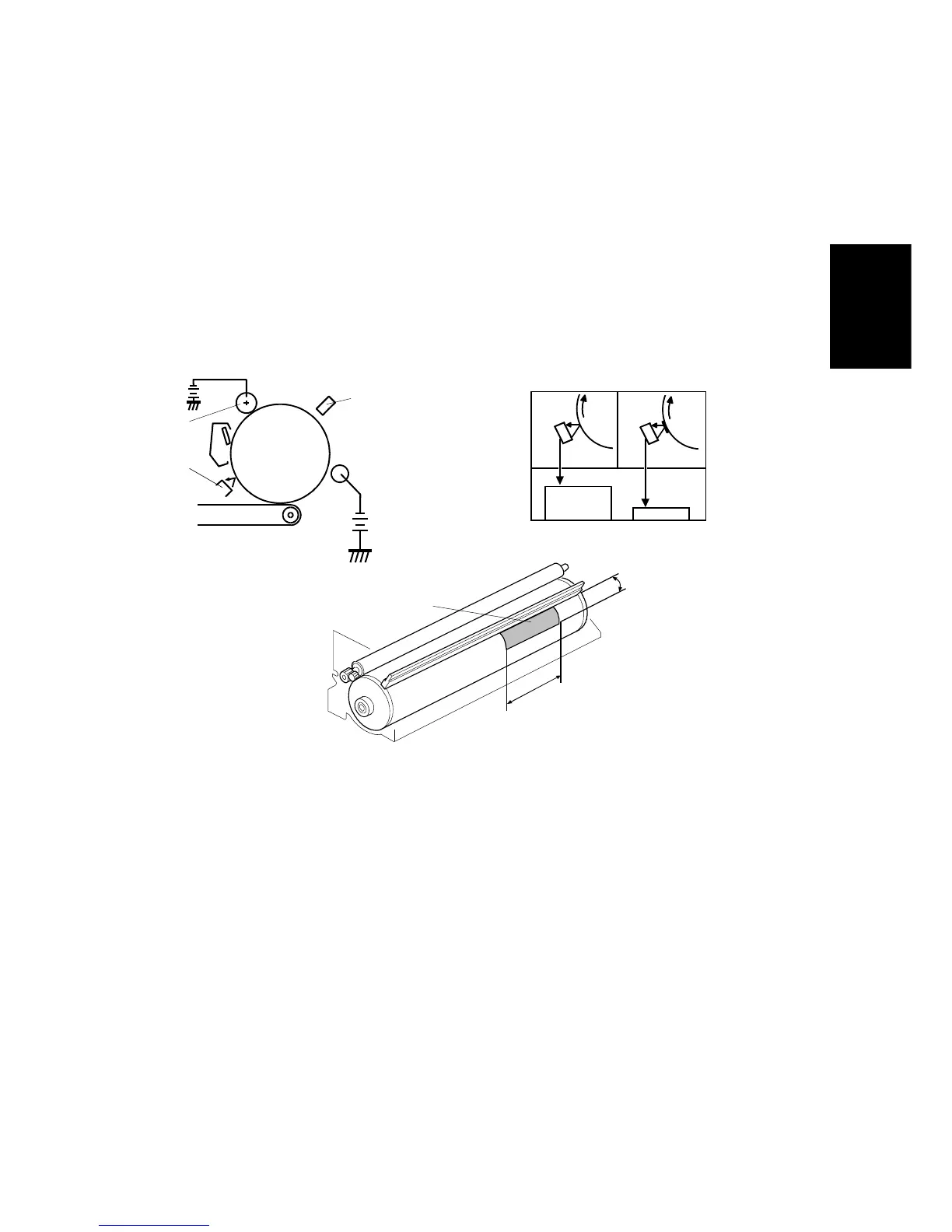

The ID sensor [A] (below the drum cleaning section) checks the following

voltages.

• V

SG

: the ID sensor output when checking the erased drum surface.

•

V

SP

: the ID sensor output when checking the Vsp pattern image.

In this way, the reflectivity of both the erased drum surface and the pattern

on the drum are checked. This compensates for any variations in light

intensity from the LED component of the sensor or the reflectivity of the drum.

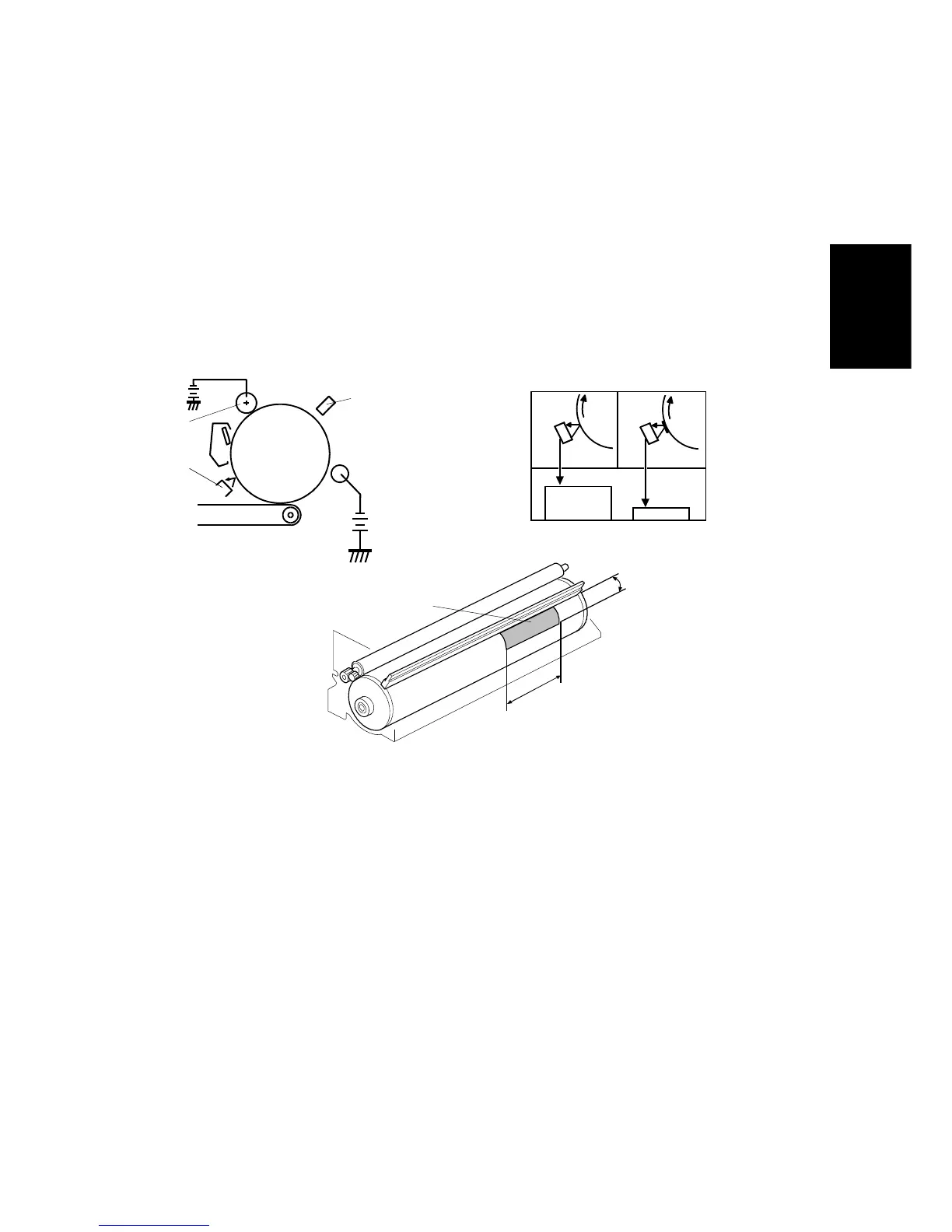

The V

SP

pattern [B] is made on the OPC drum by the drum charge roller [C]

and the erase lamp [D].

65 mm

35 mm

[B]

[C]

[A]

[D]

Dev.

bias

Drum

LED

ON

LED

ON

V

SG

V

SP

Detailed

Descriptions

STM 2-11 A156/A160/A162

Loading...

Loading...