3.3 DRUM CHARGE ROLLER CLEANING

If the drum charge roller gets dirty, drum charge efficiency decreases. This

affects the copy quality, for example causing vertical white lines.

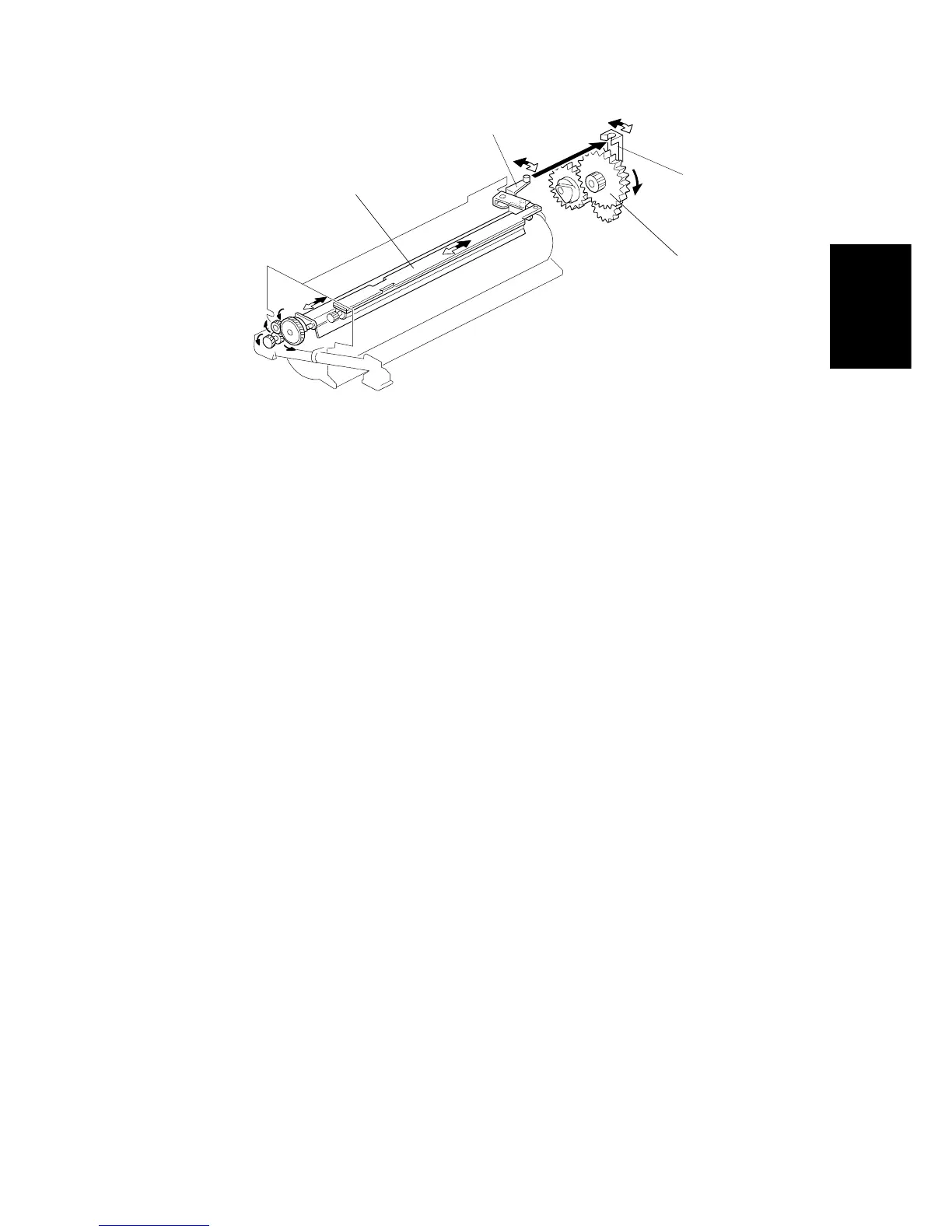

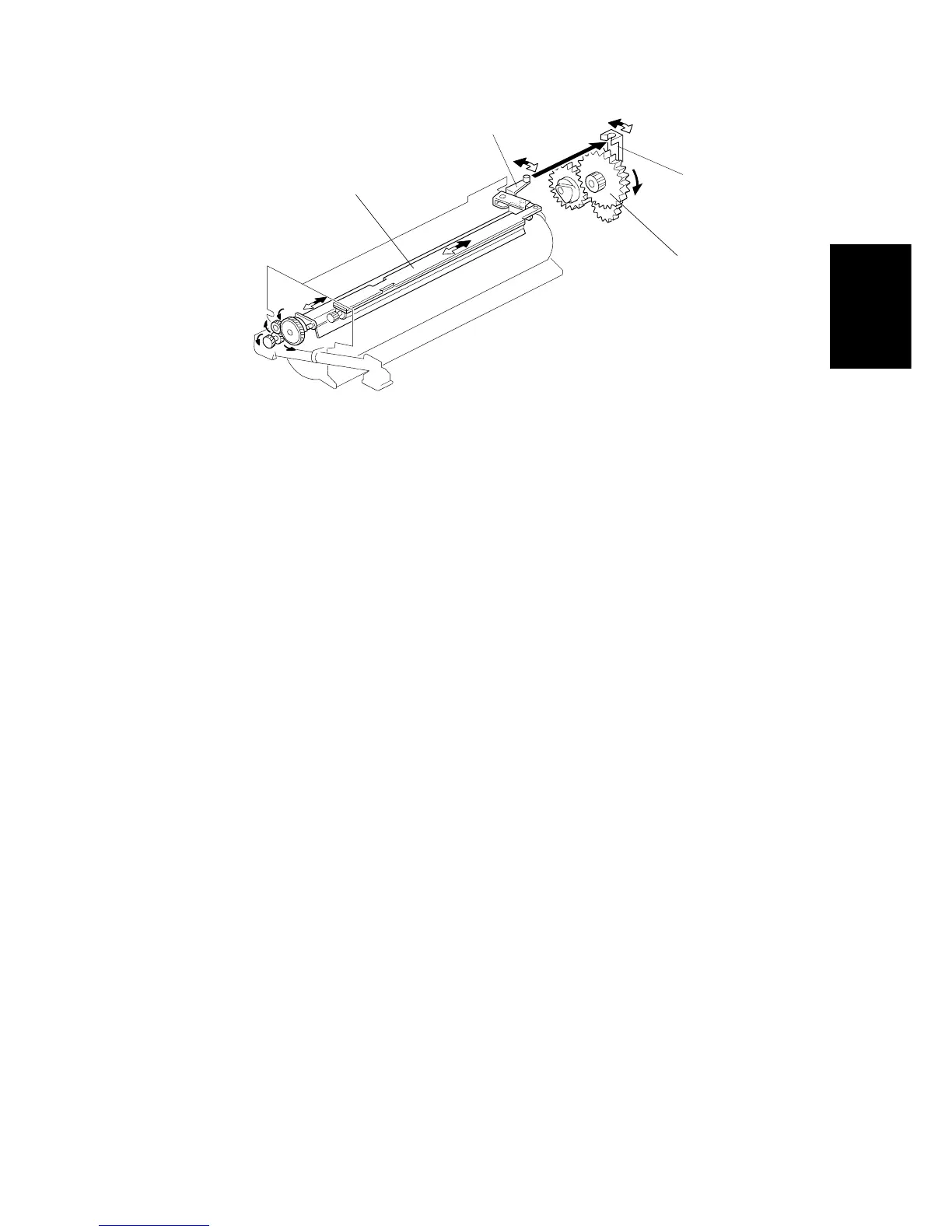

While the drum charge roller is away from the drum but still rotating, it

brushes against the cleaning pad [A], which helps to keep it clean.

However, there is a specific drum charge roller cleaning routine which is

described below. It is executed at the following intervals:

(1) For 2 seconds at the end of every job

(2) For 10 seconds after the copy job interval set by SP2-901.

After the copy job, the drum charge roller comes away from the drum and

contacts the drum charge roller cleaning pad [A]. The main motor still rotates

during cleaning and drives the gear [B] to swing the lever [C] via an eccentric

cam. This lever swings the arm [D] and the arm gives a side-to-side

movement to the drum charge roller cleaner.

The cleaning interval set by SP2-901 is as follows:

SP2-901 setting: 0: Every 1000 copies (10 seconds) [default]

1: Every 500 copies (10 seconds)

2: Every 200 copies (10 seconds)

3: Every 100 copies (10 seconds)

For a user who mainly makes consecutive high volume copy runs, the drum

charge roller is likely to get dirty early, because the interval between jobs

(and thus the interval between end-of-copy-job cleaning runs) is longer than

for small volume intermittent copy runs. In this case, the copy count interval

for cleaning must be reduced with SP2-901, to have the ten-second cleaning

routine done more often.

[C]

[D]

[A]

[B]

Detailed

Descriptions

STM 2-37 A156/A160/A162

Loading...

Loading...