2.Detailed Descriptions

102

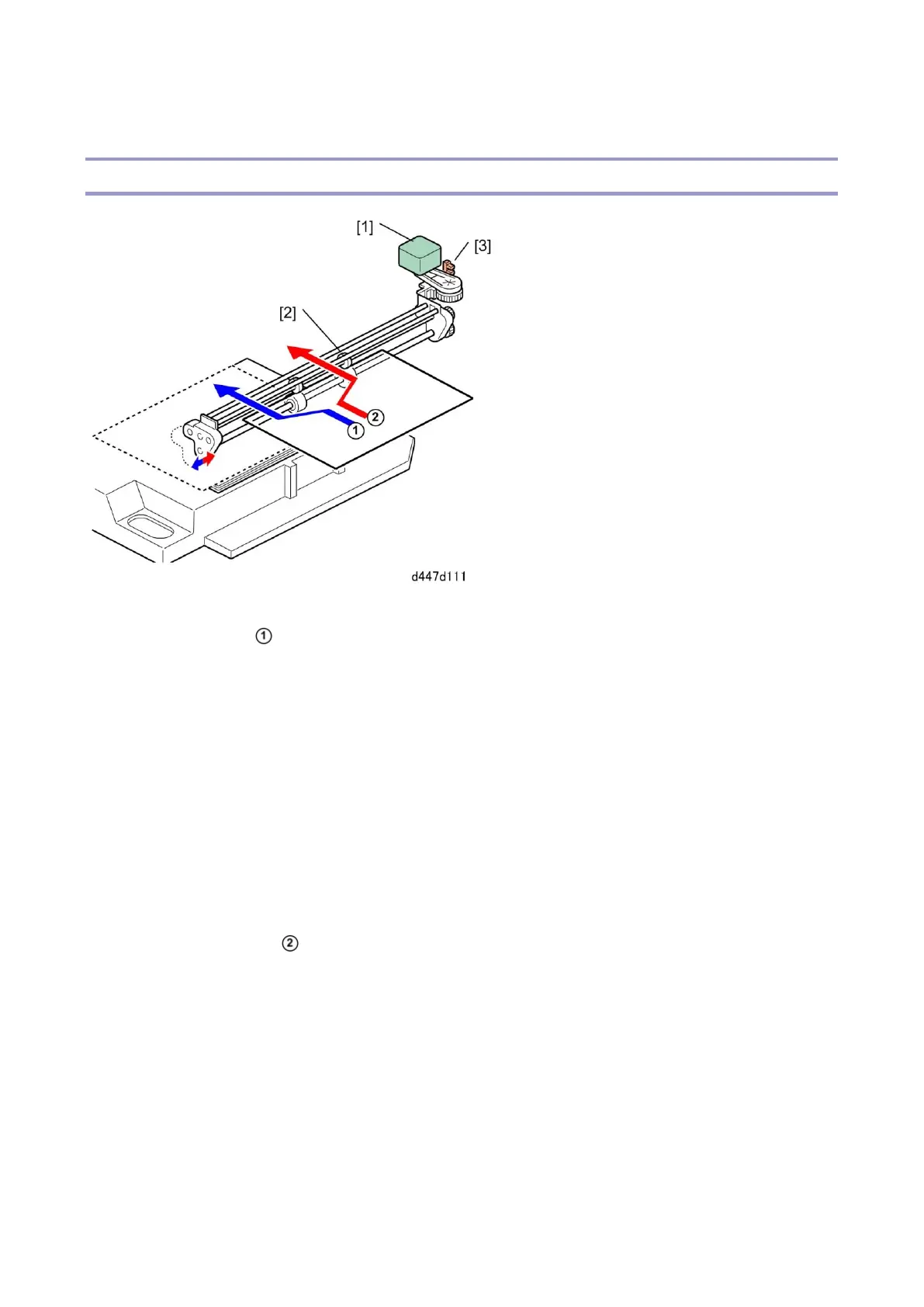

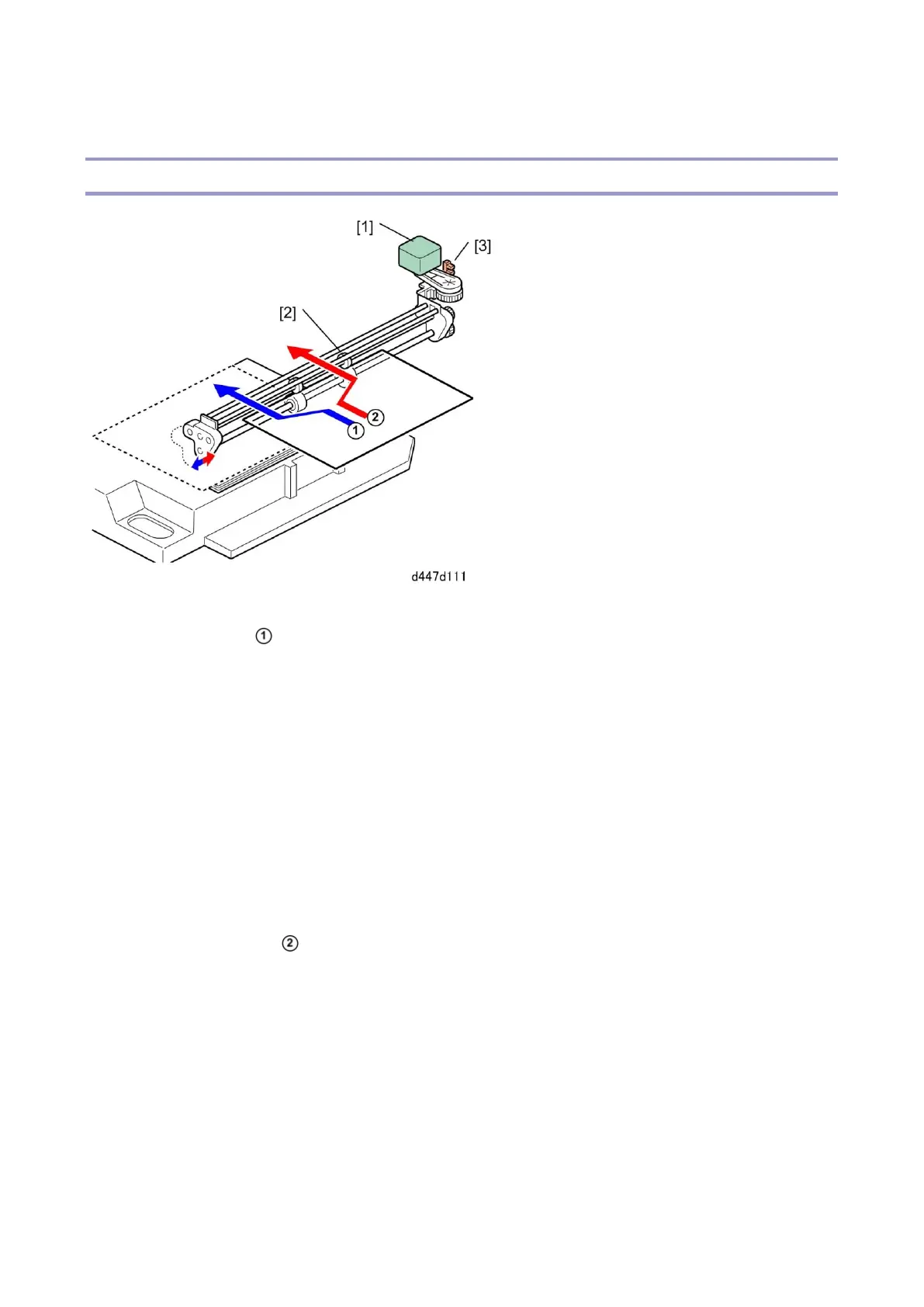

Paper Shift and Alignment

Paper Shift

In the shift mode, the paper is fed past the open shift tray junction gate and onto the shift tray.

1. When the first set starts to feed:

The leading edge of the paper is fed into the nip of the shift rollers (drive and idle roller pair.)

After the trailing edge of the sheet leaves the nip of the upstream rollers, the shift motor [1]

switches on.

The belt pushes the shift rollers [2] with the paper still feeding between them to the front and

stops.

The paper feeds onto the tray at the forward position.

The shift motor reverses and rotates the belt until the shift rollers return to the home position.

The shift HP sensor [3] detects the home position of the rollers and switches off the shift motor.

This sequence repeats for the 1st set until the last sheet has been fed.

The amount of shift from the center is fixed at 10 mm. (This cannot be adjusted.)

2. When the second set starts to feed:

The leading edge of the paper is fed into the nip of the shift rollers (drive and idle roller pair.)

After the trailing edge of the sheet leaves the nip of the upstream rollers, the shift motor [1]

switches on.

The belt pulls the shift rollers [2] with the paper still feeding between them to the rear and

stops.

The paper feeds onto the tray at the rear position.

The shift motor reverses and rotates the belt until the shift rollers return the home position. The

shift HP sensor [3] detects the home position of the rollers and switches off the shift motor.

This sequence repeats for the 2nd set until the last sheet has been fed.

Loading...

Loading...