Loading...

Loading...

Do you have a question about the Seco Group AJ 102 and is the answer not in the manual?

| Brand | Seco Group |

|---|---|

| Model | AJ 102 |

| Category | Lawn Mower |

| Language | English |

Follow safety instructions meticulously for safe operation and to maintain warranty.

Visual symbols and their corresponding safety meanings for machine operation.

Guidelines for the intended use of the self-propelled mowing machine in various environments.

Overview of the machine's main components and their functions.

List of key equipment and components integrated into the mowing machine.

Details of the identification plate and the information it contains.

Procedure for inspecting the machine and its components after removing packaging.

Steps for assembling steering wheel, seat, and connecting the accumulator.

Steps for assembling suspension and attaching the grass collecting bin.

Procedure for verifying the engine oil level as per maintenance guidelines.

Safe procedures for refuelling the machine with petrol, including precautions.

Detailed explanation of each control element and its operation on the machine.

Operation of ignition, gas control lever, mowing mechanism switch, and choke.

Operation of travel pedal, parking brake, by-pass lever, differential lock, and steering.

Adjusting cutting height, operating mulching flap, and fuel shut-off.

Key procedures for operating the machine, including starting, stopping, and mowing.

Procedures for starting, stopping the engine, and engaging/disengaging the mowing mechanism.

Guidelines for adjusting mowing height, travel, speed, slopes, and discharging grass.

Overview of maintenance tasks and their recommended intervals (hours, monthly, seasonal).

Maintaining correct tyre pressure for optimal performance and safety.

Post-operation tasks to keep the machine clean and in good condition.

Detailed steps for cleaning the machine after use, including safety warnings.

Instructions for washing the machine, avoiding electrical components, and flushing the mowing mechanism.

Guidance on maintaining the accumulator according to its operating instructions.

Procedures for maintaining the engine, including oil, filters, and spark plugs.

Procedures for checking and changing the engine oil.

Steps for maintaining fuel and air filters for optimal engine performance.

Procedure for checking and maintaining the sparking plug.

Information on lubrication points and intervals for machine longevity.

Instructions for replacing burnt-out bulbs on the machine.

Procedure for replacing blown fuses to restore electrical functionality.

Safe procedure for lifting the machine using a jack and supports for maintenance.

How to replace and sharpen mowing mechanism knives for optimal cutting performance.

Checking and adjusting the steering unit for proper operation and to eliminate play.

Procedure for checking and adjusting the tension of the travel drive belt.

Ensuring correct mowing mechanism alignment and height for quality cutting.

Adjusting the tension of the mowing mechanism drive V-belt.

Step-by-step guide for safely removing the mowing mechanism from the machine.

Adjusting the tension of the belt driving the mowing mechanism knives.

Instructions or recommendation for replacing worn or damaged belts.

Procedure for safely changing the machine's wheels.

Essential maintenance for the hydrostatic gearbox, including oil level checks.

Procedure for adjusting the brakes if their efficiency decreases.

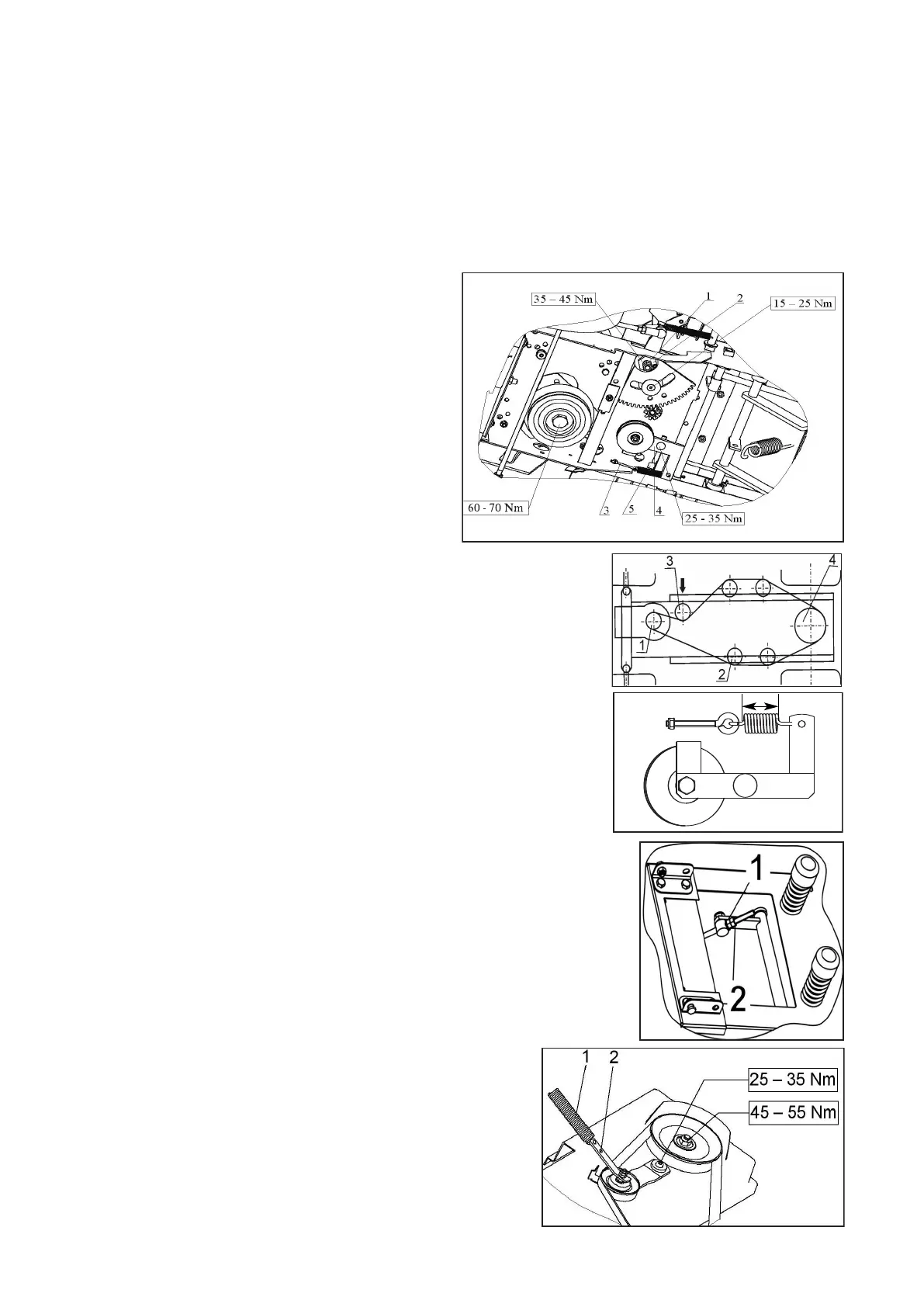

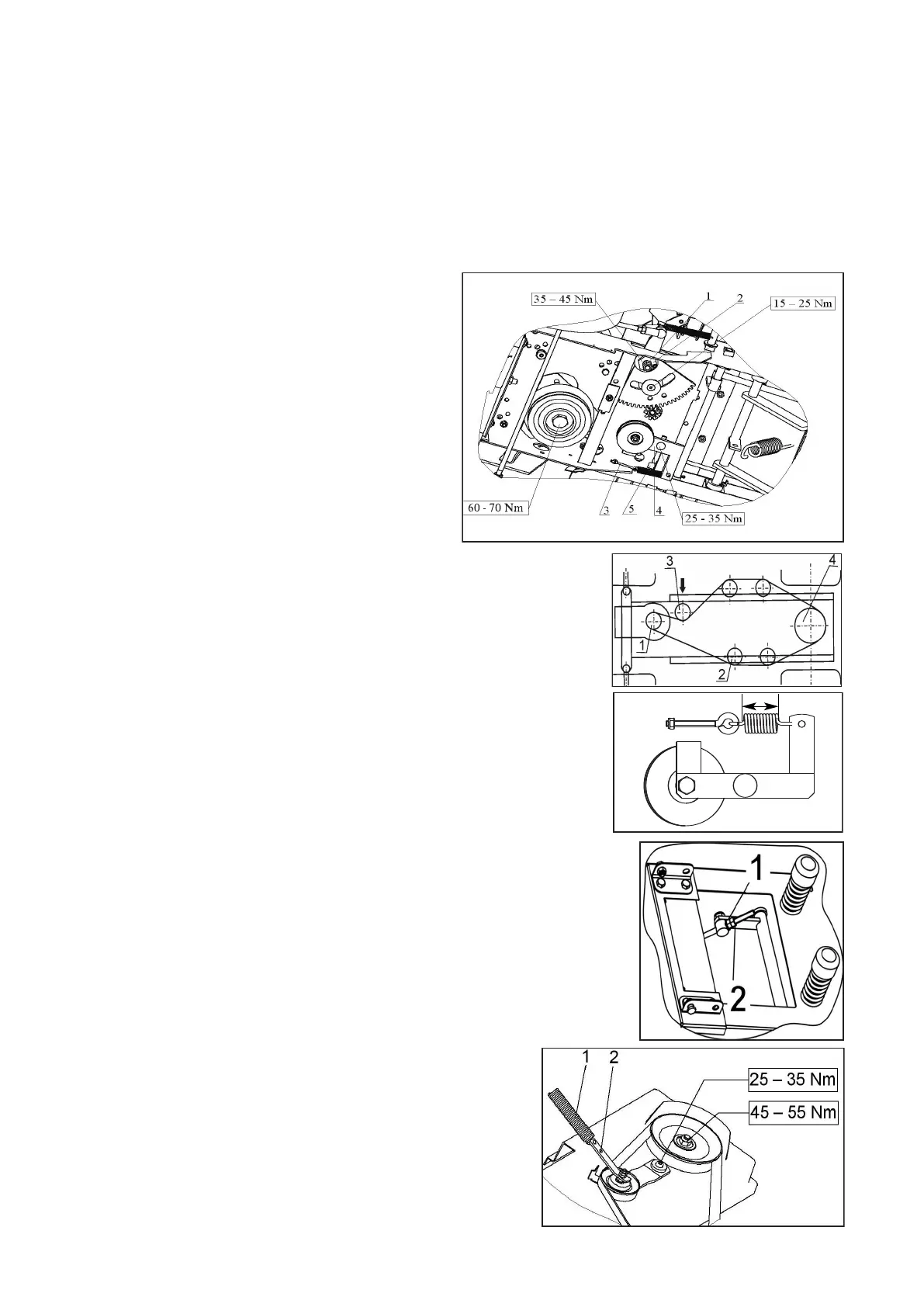

Reference table for tightening torques of various screw connections on the machine.

Common failures and defects with instructions for their diagnosis and removal.