Technical Appendix

6-50

SINUMERIK 802S base line

Start-Up

6.3.5 SAMPLE program structure

Definition of subroutine

In this SAMPLE program, the user can complile subroutines from 0 to 30, and

the function of the individual subroutine is described in the subroutine library.

See below.

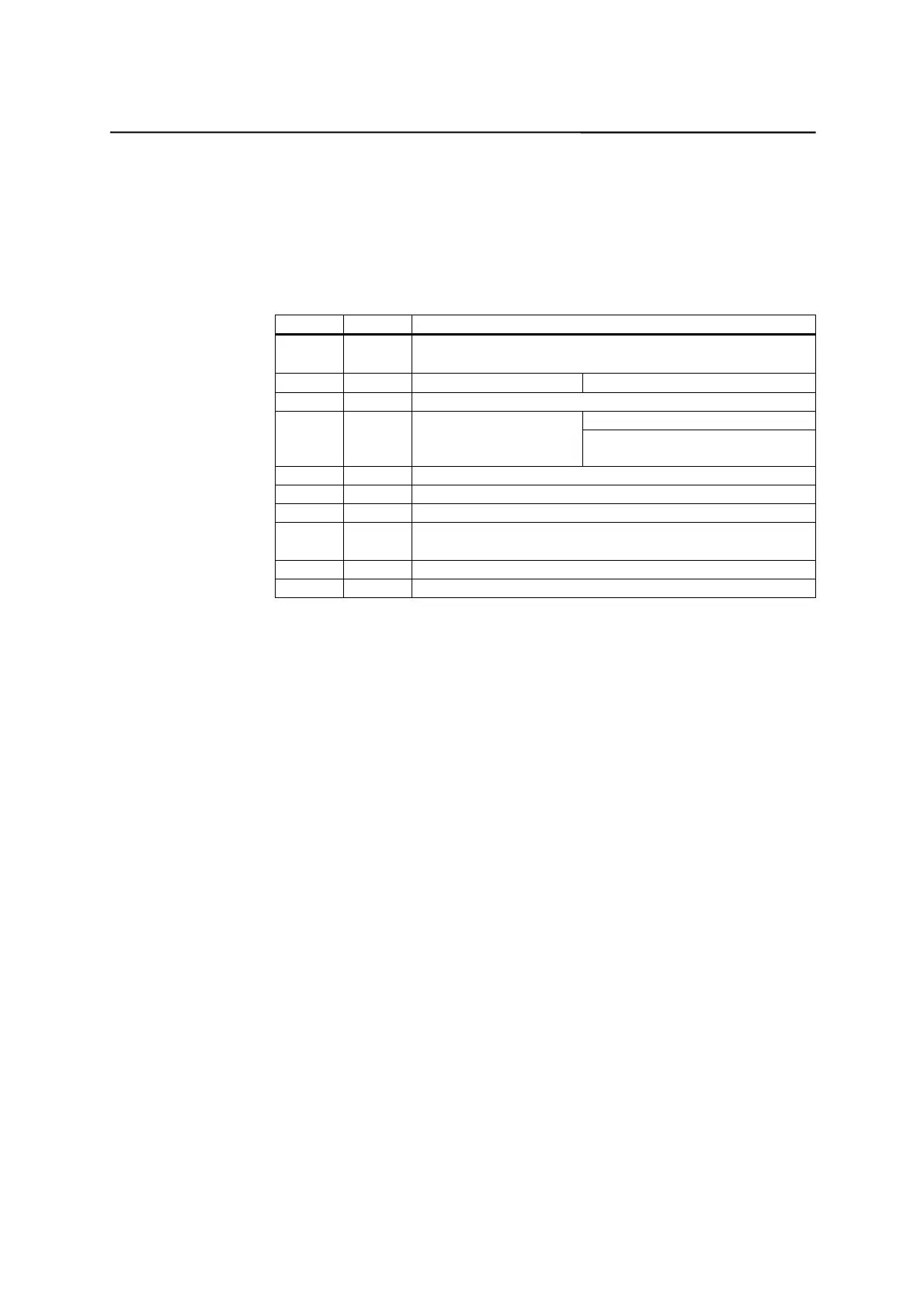

MAIN (OB1)

Seq. # SBR # subroutines

162

Input & output signals filtering (IW0/QW0 →

MW100/MW102)

232

PLC initialization →

SBR31 – customer initialization

3 33 Emergency Stop

SBR34 – Traverse key control4 38 MCP signal process

→

SBR39 – Handwheel select via

HMI

5 40 XYZ and spindle enable/disable

6 44 Coolant control

7 45 Lubrication control

835

Contactor spindle or analog spindle (0~10V or ±10V

setpoint )

9 41 Turret control

10 49 Clamping and unclamping control

I/O signal processing

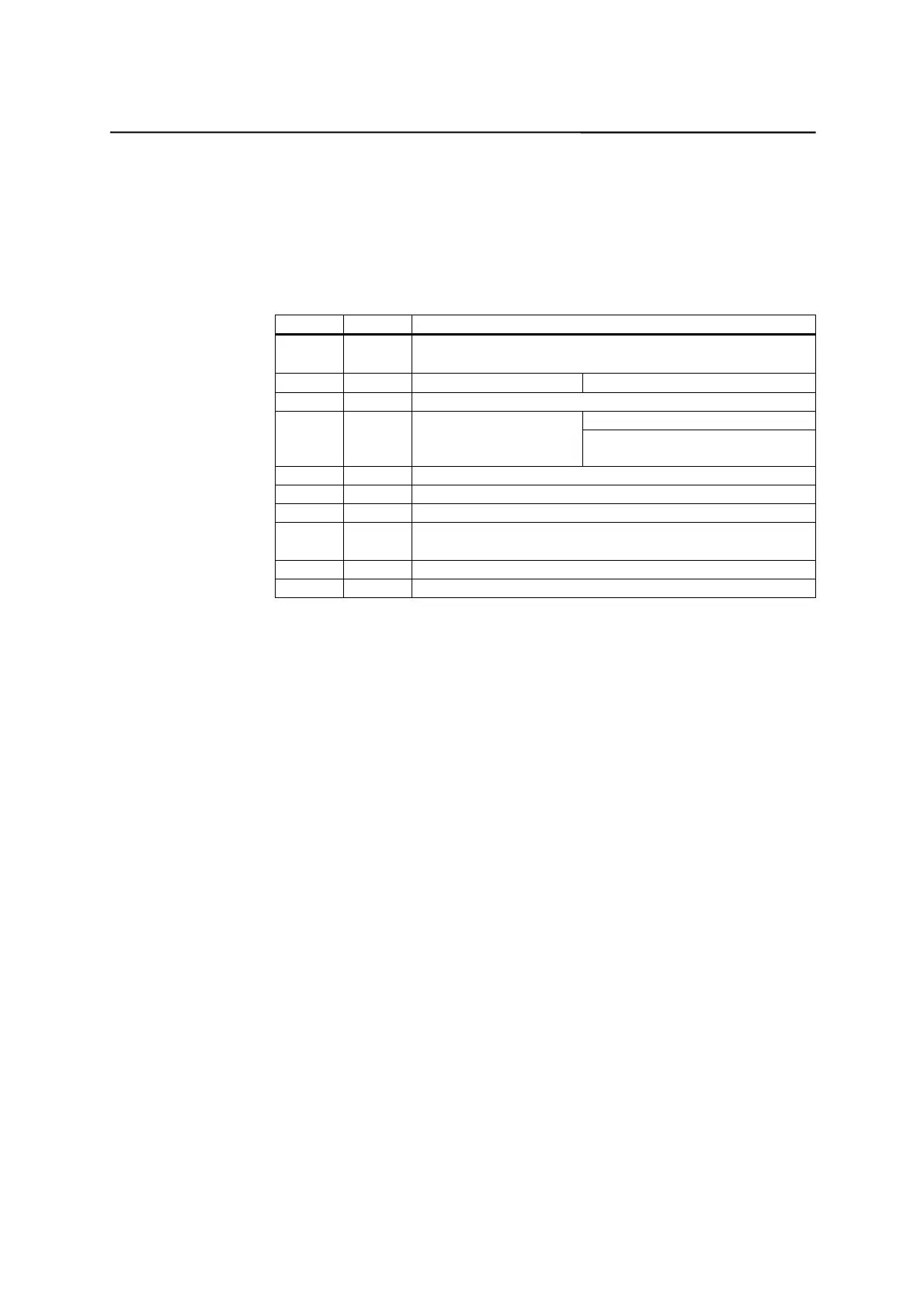

SAMPLE is designed to meet the different wiring on the machine tools, i.e. any

input can be connected as Normal Open, or Normal Close. All input and output

signals have been filtered by SBR62 FILTER. The I/O filtering is carried out

according to PLC MD14512[0], [1], [2], [3] and MD14512[4], [5], [6], [7].

Principle of I/O filter

with follow chart, it is easily know the correspondence of internal inputs and

outputs. Therefore in SAMPLE M100.0 is a buffered input for I0.0, and

M101.2 is for I1.2; M102.3 is for Q0.3 and M103.4 is for Q1.4, and so on. All

subroutines in LIBRARY are inputs/output independent.

Loading...

Loading...