Start-Up

4-34

SINUMERIK 802S base line

Start-Up

4.7.2 Starting up the axes

Overview

The SINUMERIK 802S base line has up to three stepper motor feedrate axes

(X, Y and Z). The stepper motor drive signals are output at connector X7 for

the:

z

X axis (SW1, BS1, RF1.1, RF1.2)

z

Y axis (SW2, BS2, RF2.2, RF2.2)

z

Z axis (SW3, BS3, RF3.1, RF3.2)

z

Spindle(SW4, RF4.1, RF4.2)

Additional axes

The 2nd axis in the axis order, which when milling has the function of the Y axis

can be used as an additional axis when turning. This is achieved by loading

one of the files “turnax_U.ini” or “turnax_V.ini” or “turnax_W.ini” from the

Toolbox and enabling these data.

Which files are selected is dependent on the desired axis name: U or V or W.

The additional axis is a linear axis with limited functionality, compared with the

axes X and Z. It can be traversed together with the remaining axes. If the

additional axis is traversed in a program block that contains G1 or G2/G3,

using the axes (X, Z), then it will not be assigned a component of the feedrate

F. In this case, the axis’ speed will depend on the path travel time of the axes X,

Z. Its motion starts and ends together with the axes X, Z. The axis speed,

however, cannot be greater than the limit value defined for the additional axis.

If the additional axis is programmed in a separate block, it will travel with the

active feedrate F if G1 is programmed.

Both settable offsets (G54 ... G57) and programmable offsets (G158) are

possible for the additional axis. Tool offsets are not effective in this axis.

Simulation/stepper motor drive

Setpoint output and pulse feedback can be switched between simulation and drive

operation using the axis MD 30130_CRTLOUT_TYPE and 30240_ENC_TYPE.

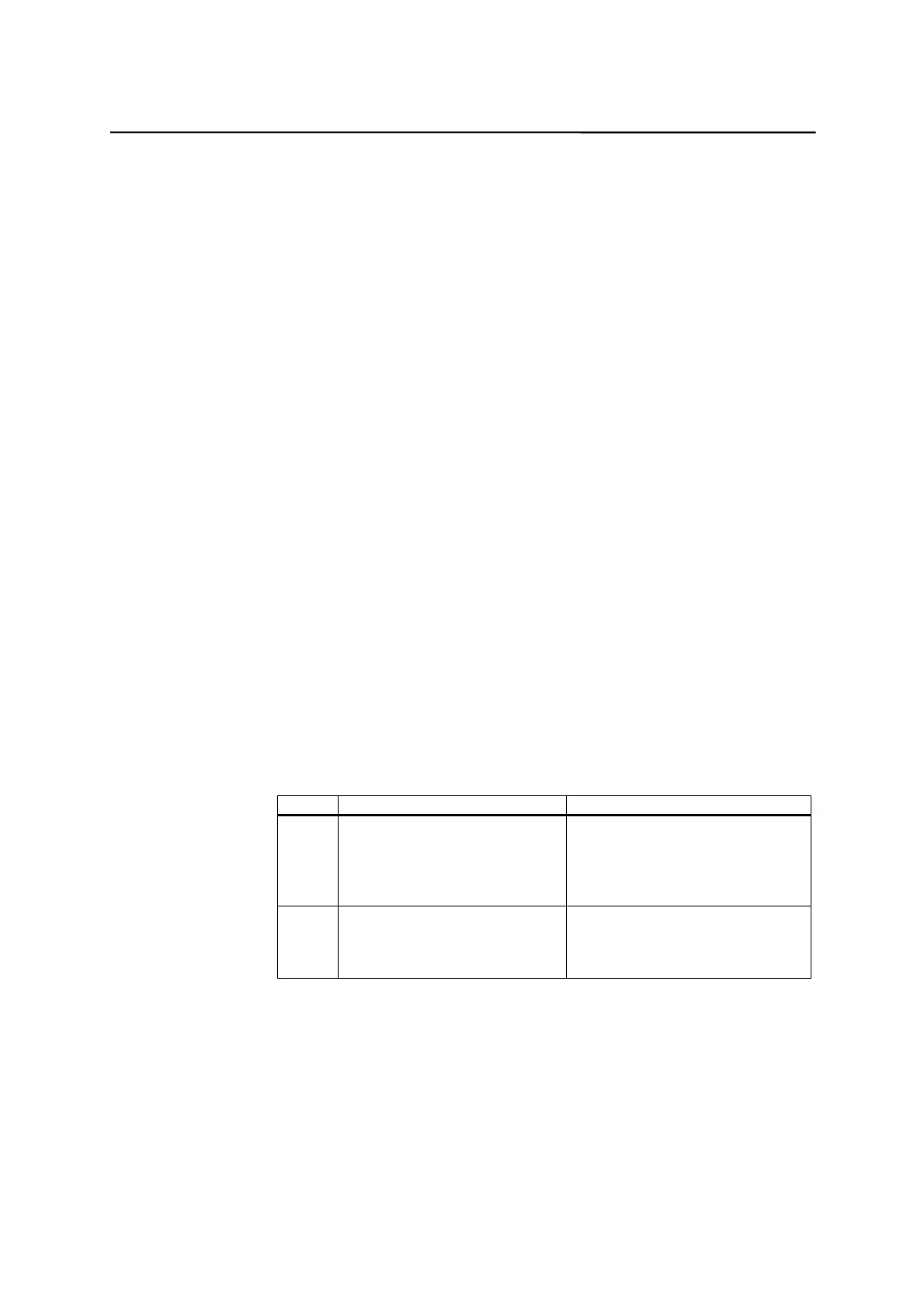

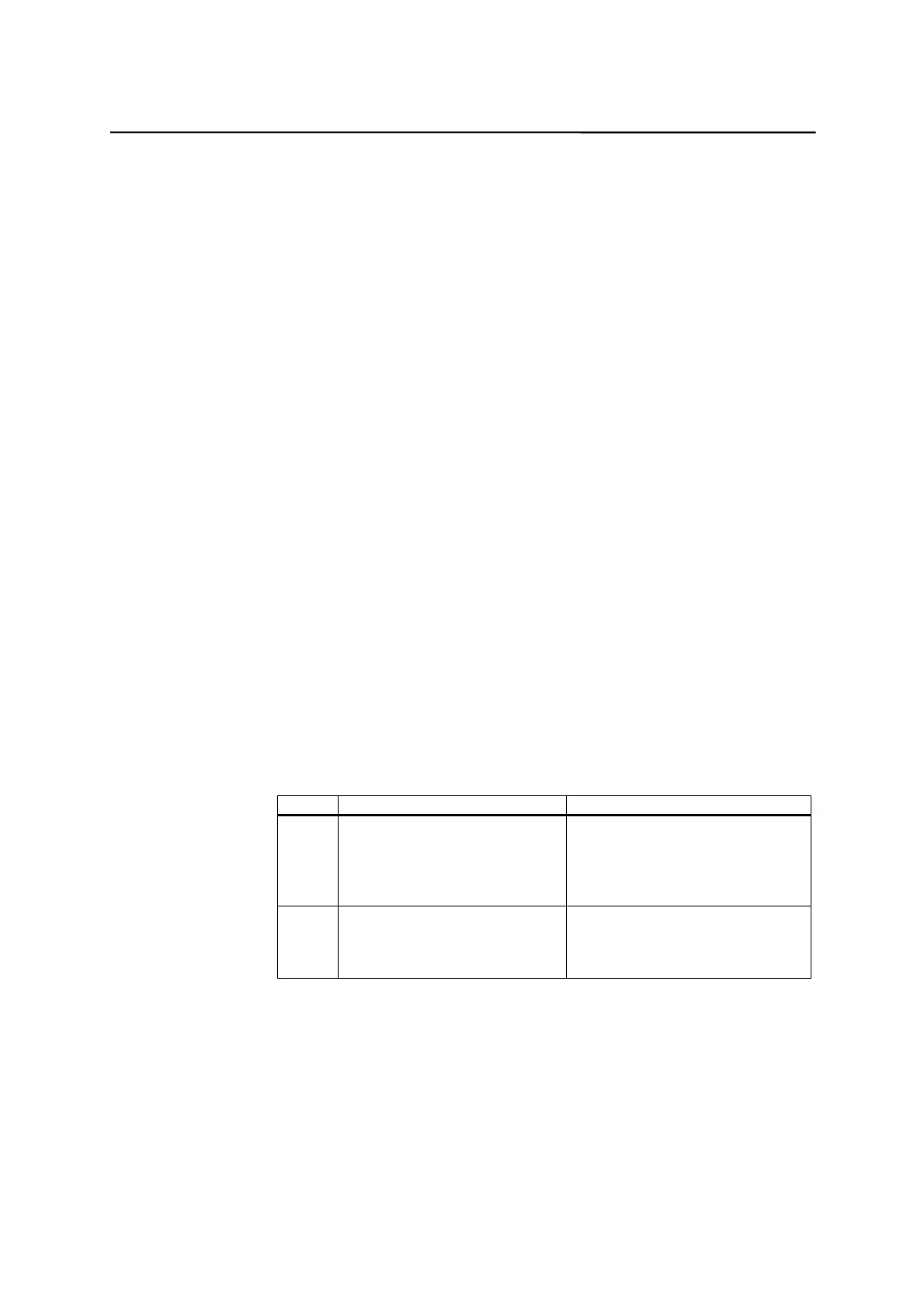

Table 4–12

MD Simulation Normal Operation

30130 Value = 0

To test the axis, the actual value

is fed back internally as an

actual value. No setpoint output

at connector X7.

Value = 2

The setpoint signals for stepper

motor operation are output at

connector X7. Real axis traversal

is possible using a servo motor.

30240 Value = 0 Value = 3

Internal pulse feedback from

setpoint output to actual value

input “ON”

Machine data default settings for stepper motor axes

The machine data list bloew contains the default machine data and their

recommended settings with stepper motor axes connected.

After the machine data have been set, the stepper motor axes are ready to

traverse, as far as the machine data are concerned, and only fine adjustments

are required.

Loading...

Loading...