Start-Up

4.3 Starting up the PLC

4-77

SINUMERIK 802S

6FC5 597–2AA00–0BP2 (01.02)

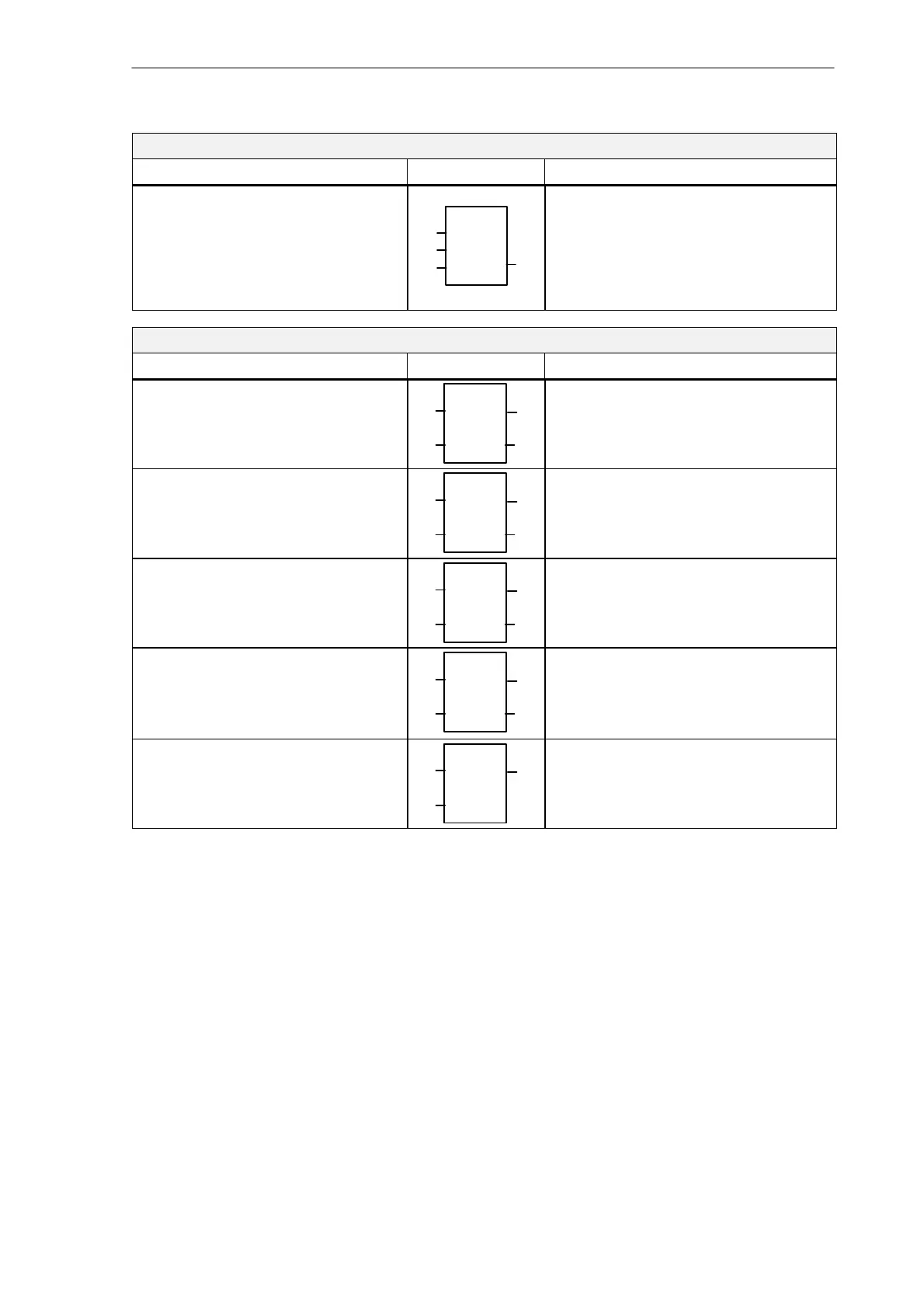

PROGRAM CONTROL FUNCTIONS

Instruction Ladder Symbol Valid Operands

Subroutine If EN ½, go to sub-

routine n.

SBR

x1

x2

x3

EN

n

(x... optional paramete

Label: Constant : 0–63

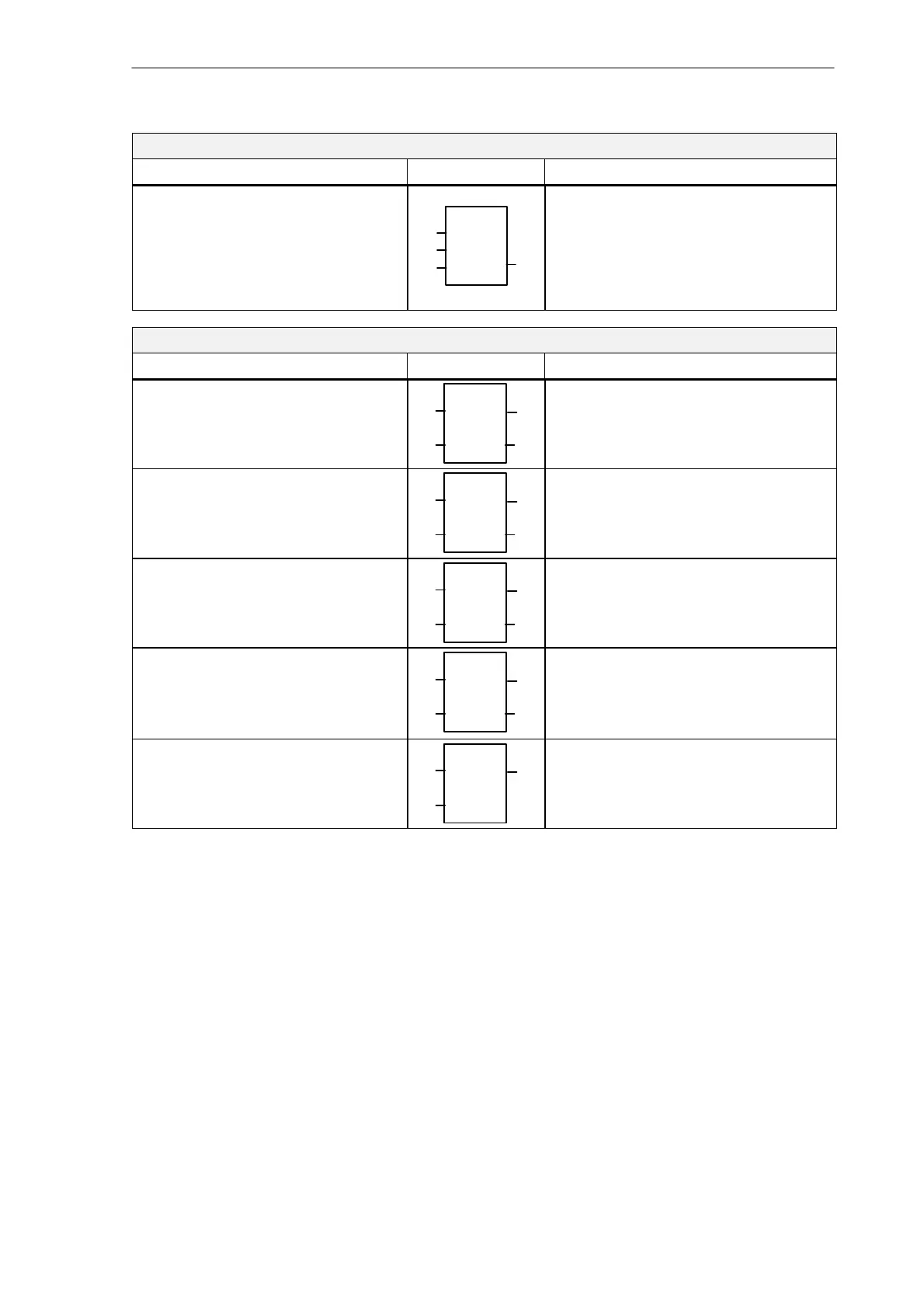

MOVE, FILL AND FIND OPERATIONS

Instruction Ladder Symbol Valid Operands

Move Byte If EN = 1,

copy i to o.

MOV_B

IN

OUT

EN

ENO

Enable: EN

In: VB, IB, QB, MB, AC, Constant, LB

Out: VB, IB, QB, MB, AC, LB

Move Word If EN = 1,

copy i to o.

MOV_W

IN

OUT

EN

ENO

Enable: EN

In: VW, T, C, IW, QW, MW, AC,

Constant, LW

Out: VW, T, C, IW, QW, MW, AC, LW

Move DWord If EN = 1,

copy i to o.

MOV_DW

IN

OUT

EN

ENO

Enable: EN

In: VD, ID, QD, MD, AC, Constant, LD

Out: VD, ID, QD, MD, AC, LD

Move Real If EN = 1,

copy i to o.

MOV_R

IN

OUT

EN

ENO

Enable: EN

In: VD, ID, QD, MD, AC, Constant, LD

Out: VD, ID, QD, MD, AC, LD

Swap Bytes If EN = 1,

exchange MSB and

LSB of w.

SWAP

IN

EN

ENO

Enable: EN

In: VW, IW, QW, MW, T, C, AC, LW

4.3.7 Programm organization

Each programmer should divide the user program into several closed program sections (sub-

routines). The S7–200 programming language allows the user to create structured user pro-

grams. There are two program types – main programs and subroutines. Eight program levels

are possible.

A PLC cycle can be a multiple of the control–internal interpolation cycle (IPO cycle). The ma-

chine manufacturer must set the PLC cycle according to his/her own requirements (see ma-

chine data “PLC_IPO_TIME_RATIO”). The ratio IPO/ PLC of 1:1 is the fastest possible cyclic

processing.

Loading...

Loading...