Start-Up

4.7 Commissioning

4-85

SINUMERIK 802S

6FC5 597–2AA00–0BP2 (01.02)

After the machine data have been set, the stepper motor axes are ready to traverse, as far as

the machine data are concerned, and only fine adjustments are required.

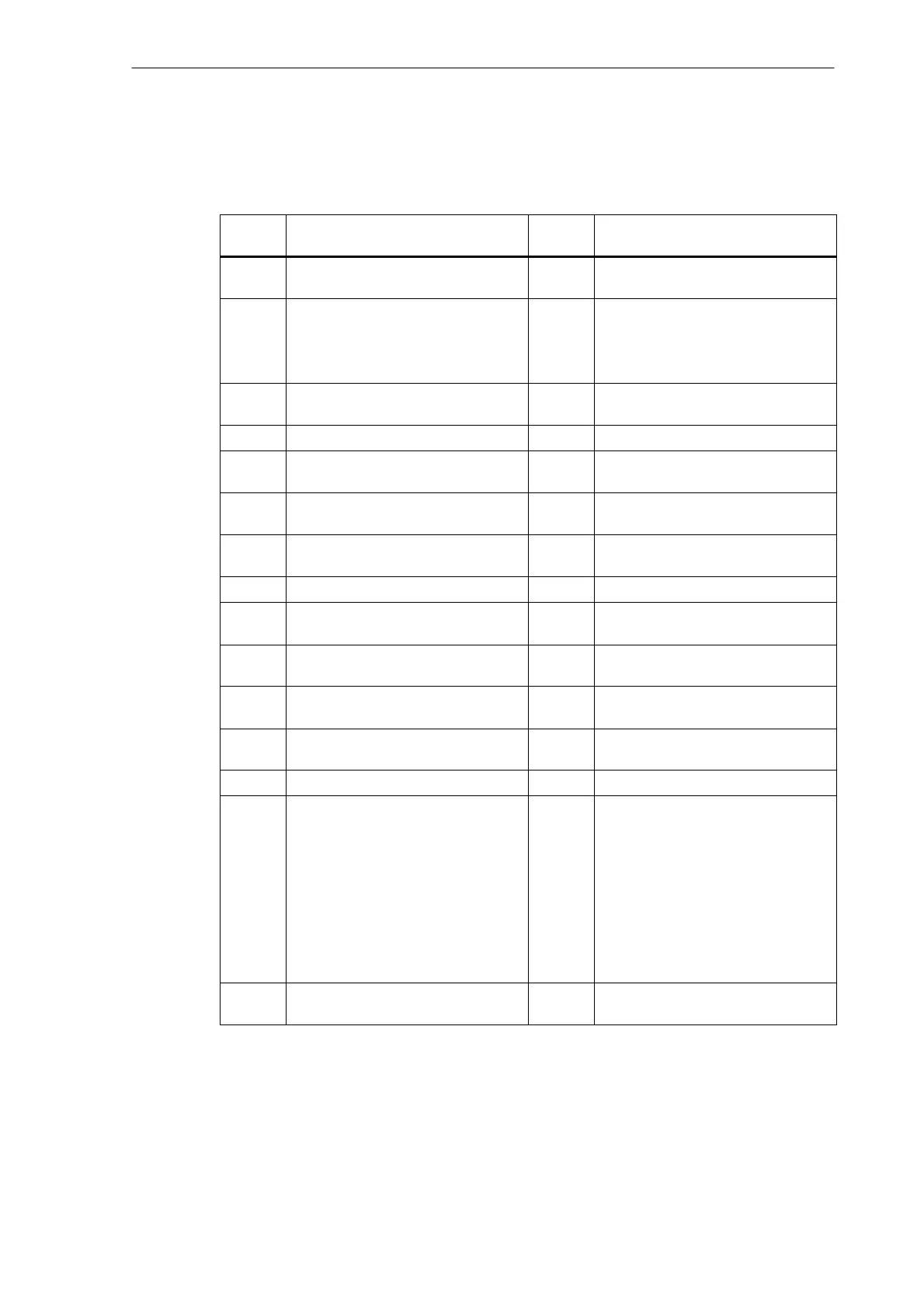

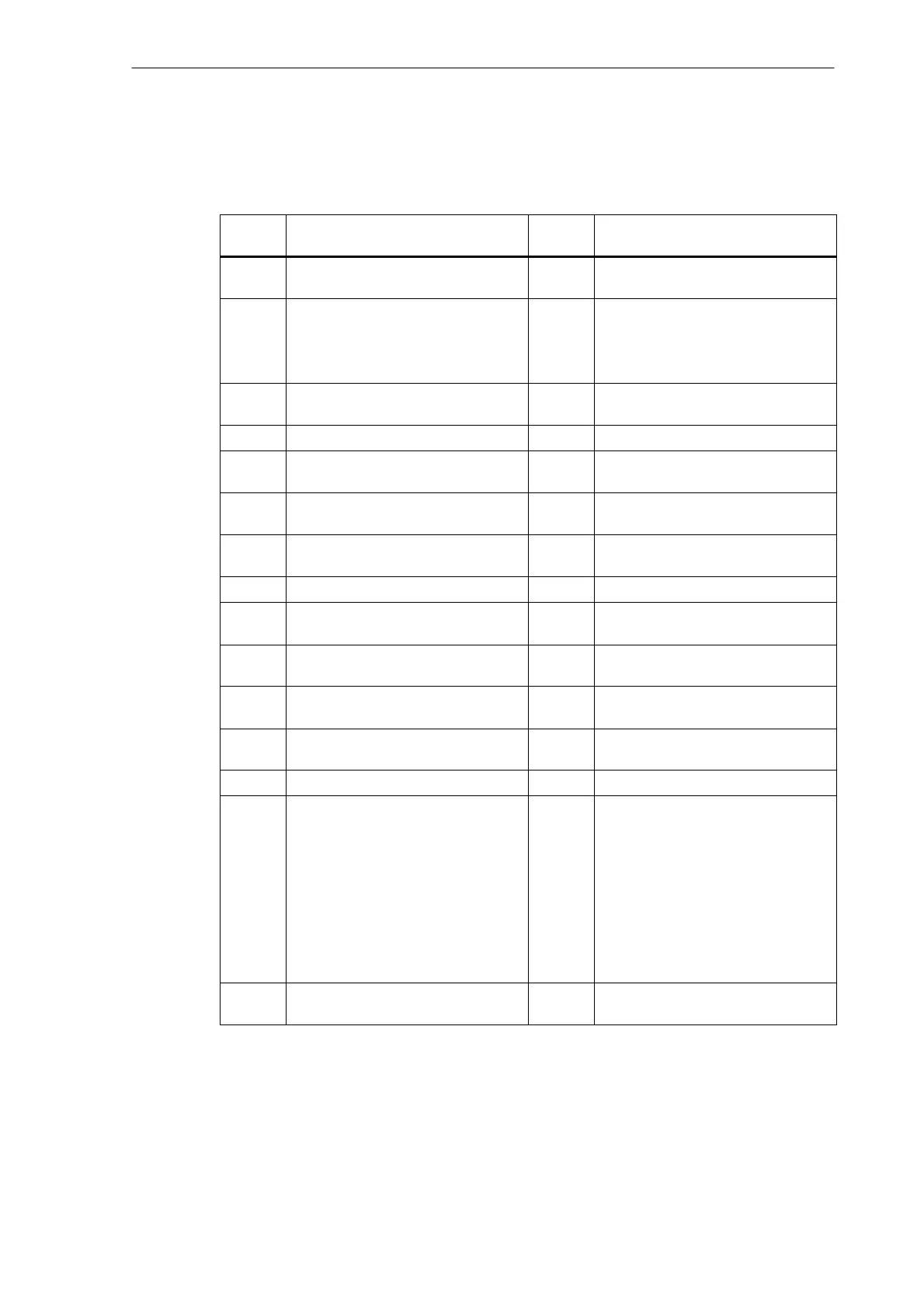

Number Description

Default

Value

Setting or Remark

30130

Output type of setpoint (setpoint

branch): 0

0 2

30240

Type of actual value acquisition (ac-

tual position value) (encoder no.)

0: Simulation

3: Encoder for stepper motor

0 3

31020

Encoder markings per revolution (en-

coder no.)

1000 Steps per stepper motor revolution

31030 Pitch of leadscrew 10 Leadscrew pitch

31050

31060

Denominator load gearbox (control

parameter no.): 0...5

1

Load and resolver transmission ra-

tios

31100

Steps for monitoring rotation

2000

Repetition cycle of BERO in measu-

ring system increments

31400

Schritte pro Schrittmotorumdrehung

1000

Steps per stepper motor revolution

(must be identical to MD 31020)

32000 Maximum axis velocity 10000 30000 (max. axis velocity)

32100

Traversing direction (not control di-

rection)

1 Reversal of direction of motion

32110

Sign actual value (control direction)

(encoder no.)

1 Measuring system reversal

32200

Servo gain factor (control parameter

set no.): 0...5

2,5 2.5 (position controller gain)

32260

Rated motor speed (setpoint

branch): 0

3000 Motor speed

34070 Reference point positioning velocity 300 Positioning speed when referencing

34200

Type of position measuring system

0: No ref. point appr.; if absolute en-

coder exists: REFP_SET_POS ac-

cepted

1: Zero pulse (on encoder track)

2: BERO

3: Distance-coded reference marks

4: Bero with two edges

5: BERO cam

1

2: Single–edge BERO

4: Double–edge BERO

36200

Threshold value for velocity monitor-

ing (control parameter set no.): 0...5

11500

Threshold value for velocity monito-

ring

To solve monitoring problems, set the following machine data:

Loading...

Loading...