Load Weighing Device

September 29,2021 ©2021 Smartrise Engineering, Inc. All Rights Reserved Page 7

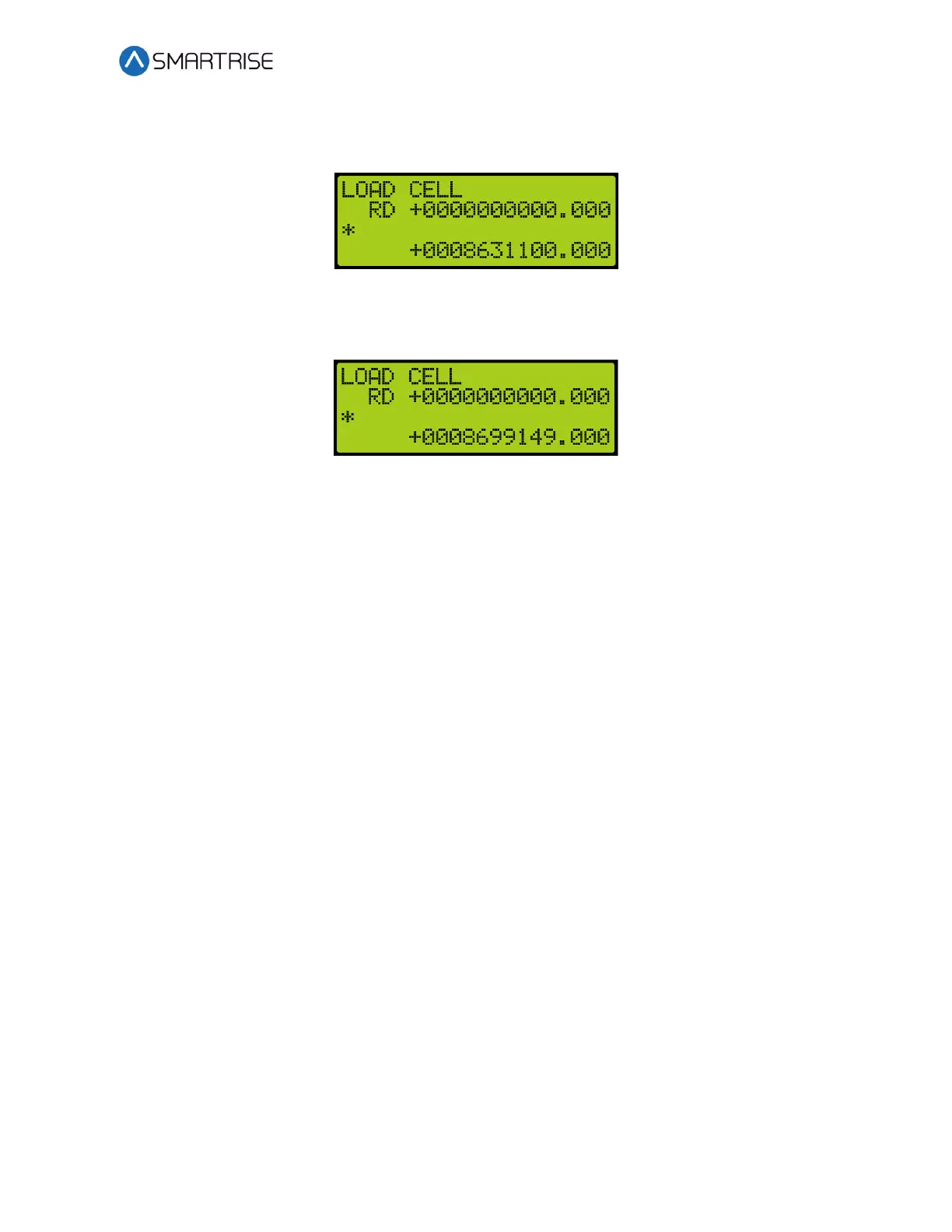

9. From the Requests menu, scroll and select LOAD CELL. After a short delay, a large

random value should appear on the screen. Record this value.

Figure 16: LOAD CELL Menu – Initial Value

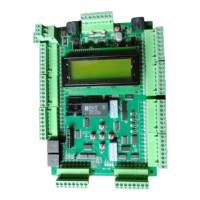

10. Add weight to the car and record the new load cell value.

Figure 17: LOAD CELL Menu – With Weight Added

11. Have all sensors been tested?

a. If all sensors have been tested, go to step 13.

b. If all sensors have not been tested, go to step 12.

12. Verify both values do not read zero or 16,777,000, and the second number is greater

than the first.

a. If both values do not read zero or 16,777,000, and the second number is greater

than the first, remove the weight from the car and go to step 9 for the new sensors.

b. If both values read zero or 16,777,000, or the second number is not greater than the

first, double check the sensor wiring.

• If the value is unchanged this could indicate the crosshead beam is not level, or

the sensor is over or under tightened. Go to step 9.

• If the polarity of the signals is wrong, which can occur if the sensor is installed on

the wrong side of the crosshead, the black and red wires of the sensor can be

swapped at the LWD. Go to step 9.

13. After each sensor’s installation has been verified, wire the sensors in parallel to the

LWD. See Table 1.

14. Press the left button until LOAD WEIGHER SETUP menu displays.

15. From the LOAD WEIGHING SETUP menu, scroll and select Enter Requests. See Figure 15.