9-1

| Speed control for rotor and assembly of divided rotor

Annex 9 Speed control for rotor and assembly of divided rotor

9.1 Speed control

The cabinet with the speed control system for the rotor is installed behind the inspection door in the rotor section.

The cabinet contains the speed controller with all components, terminal blocks, LED displaying the operation mode, the

dual position DIP switch with 8 sliding levers for programming the rotor motor signal and a button for the activation of

the test mode.

Through the different combinations of the 8 sliding levers of this dual position DIP switch, the correct signal is available

for the 3 different motors used for the 12 sizes of air handling units. The sliding levers are set and the function is

checked at the factory. The positions of the levers appear from the tables below.

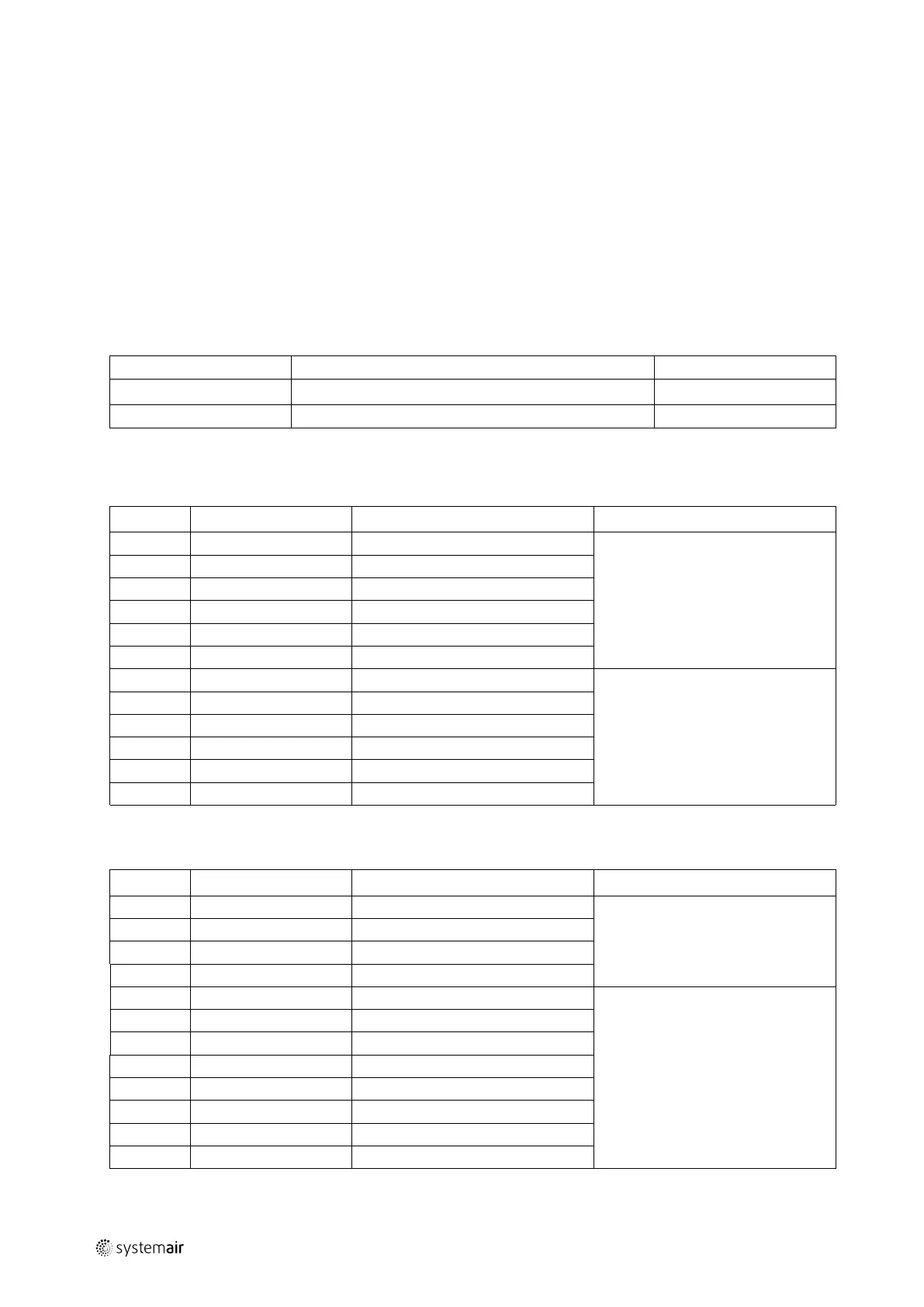

9.1.1 Selection of correct signal via the 8DIP switch levers

Position Function

Code

Up Active = ON 1

Down

Deactivated = OFF

0

The factory sets the positions of the 8 DIP switch levers for the maximum of 12 revolutions per minute for standard

temperature exchangers and for sorption-hybrid exchangers. The position of each of the 4 DIP switches to the left is

shown below.

Geniox

Pulley Position for DIP switches to the left

Motor

10 54 0000 90TYD-S214-M 2.8Nm

11 54 0000

12 54 1000

14 77 0000

16 77 1000

18 77 1000

20 85 0100 120TYD-S214-M 5.5Nm

22 95 0100

24 106 0100

27 118 0100

29 112 1100

31 112 1100

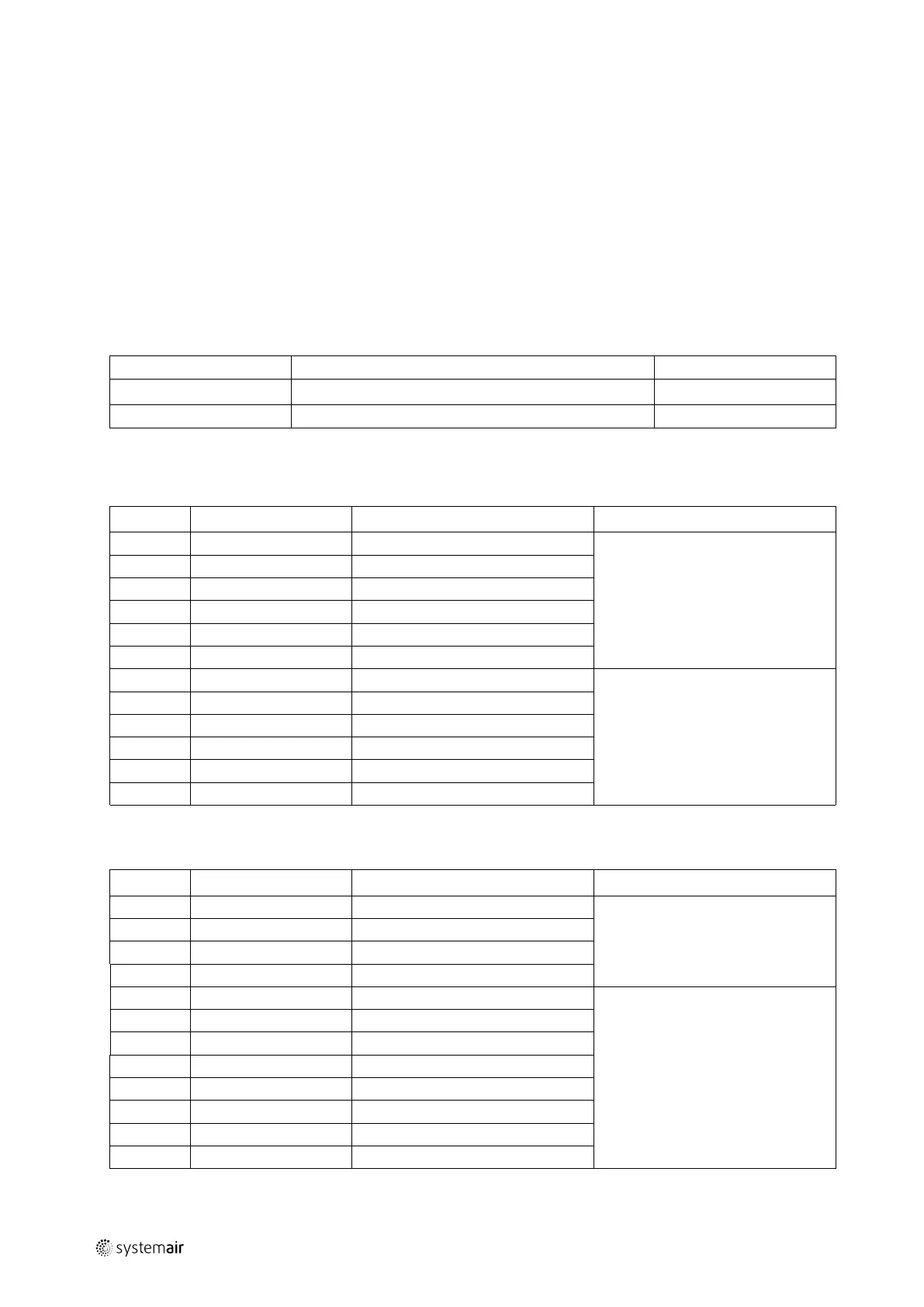

The factory sets the positions of the 8 DIP switch levers for the maximum of 20 revolutions per minute for sorption

exchangers. The position of each of the 4 DIP switches to the left is shown below.

Geniox

Pulley Position for DIP switches to the left

Motor

10 70 1000 90TYD-S214-M

11 77 1000

12 95 1000

14 95 1000

16 118 0100 120TYD-S214-M

18 112 1100

20 118 1100

22 132 1100

24 132 0110

27 160 1010

29 160 0110

31 150 0110

output |

Loading...

Loading...