Calibration

Procedure—

465B Service

Adjustment

Procedure

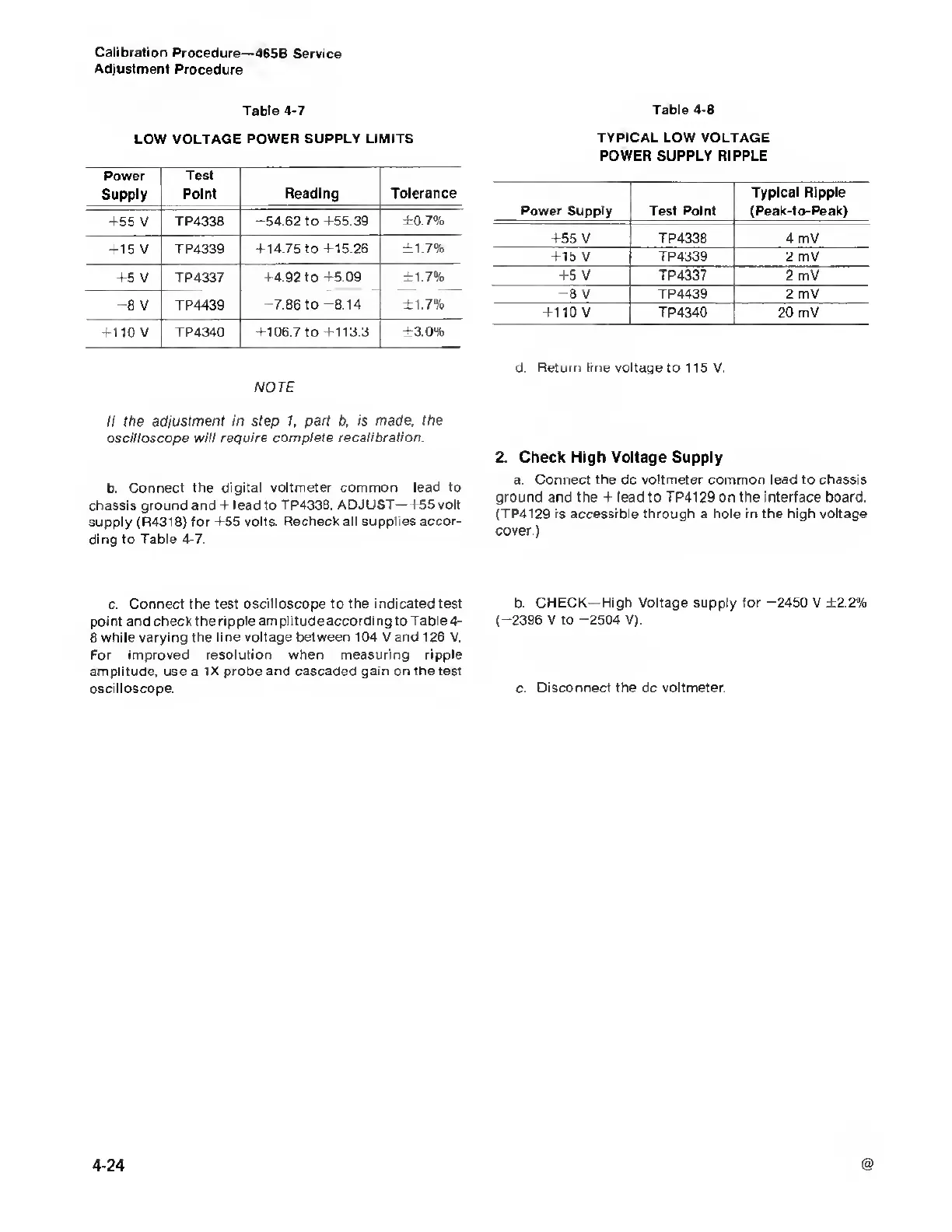

Table

4-7

LOW VOLTAGE POWER

SUPPLY LIMITS

Power

Supply

Test

Point Reading

Tolerance

+55 V TP4338

-54.62 to +55.39 ±0.7%

+15 V

TP4339 +14.75 to

+15.26 ±1.7%

+5

V

TP4337

+4.92

to

+5.09 ±1.7%

-8

V

TP4439

-7.86

to

-8.14

±1.7%

+110 V

TP4340

+106.7

to

+113.3 ±3.0%

NOTE

II the

adjustment in step

1,

part b, is

made,

the

oscilloscope will require complete

recalibration.

b.

Connect the

digital voltmeter common lead to

chassis

ground and +

lead

to TP4338.

ADJUST—+55 volt

supply (R4318) for

+55

volts.

Recheck all supplies accor-

ding to

Table

4-7.

c.

Connect the test oscilloscope to the indicated test

point and

checkthe ripple amplitude according to Table

4-

8

while varying the line voltage

between

104 V and 126 V.

For improved

resolution when measuring ripple

amplitude,

use a

IX probe and cascaded gam on the test

oscilloscope.

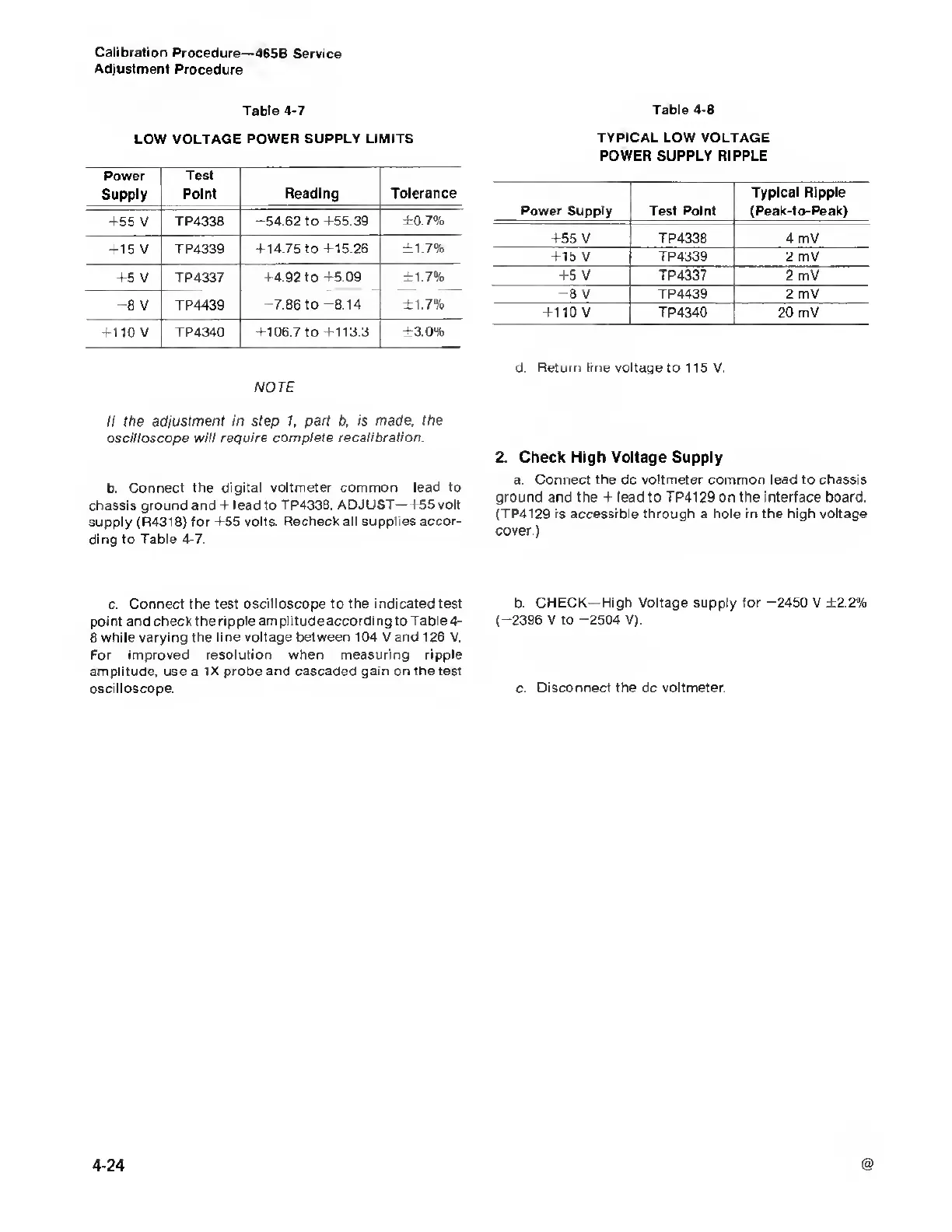

Table

4-8

TYPICAL LOW VOLTAGE

POWER SUPPLY RIPPLE

Power Supply Test Point

Typical Ripple

(Peak-to-Peak)

+55 V TP4338 4 mV

+15

V

TP4339

2

mV

+5 V TP4337

2

mV

-8

V

TP4439 2

mV

+110

V

TP4340

20 mV

d. Return line voltage to 115 V.

2. Check High Voltage Supply

a.

Connect the

dc

voltmeter common lead to chassis

ground and the + lead

to

TP4129 on the interface board.

(TP4129 is accessible through a hole in the high voltage

cover.)

b. CHECK—

High

Voltage

supply for

-2450

V ±2.2%

(-2396

V to

-2504

V).

c.

Disconnect the

dc

voltmeter.

Loading...

Loading...