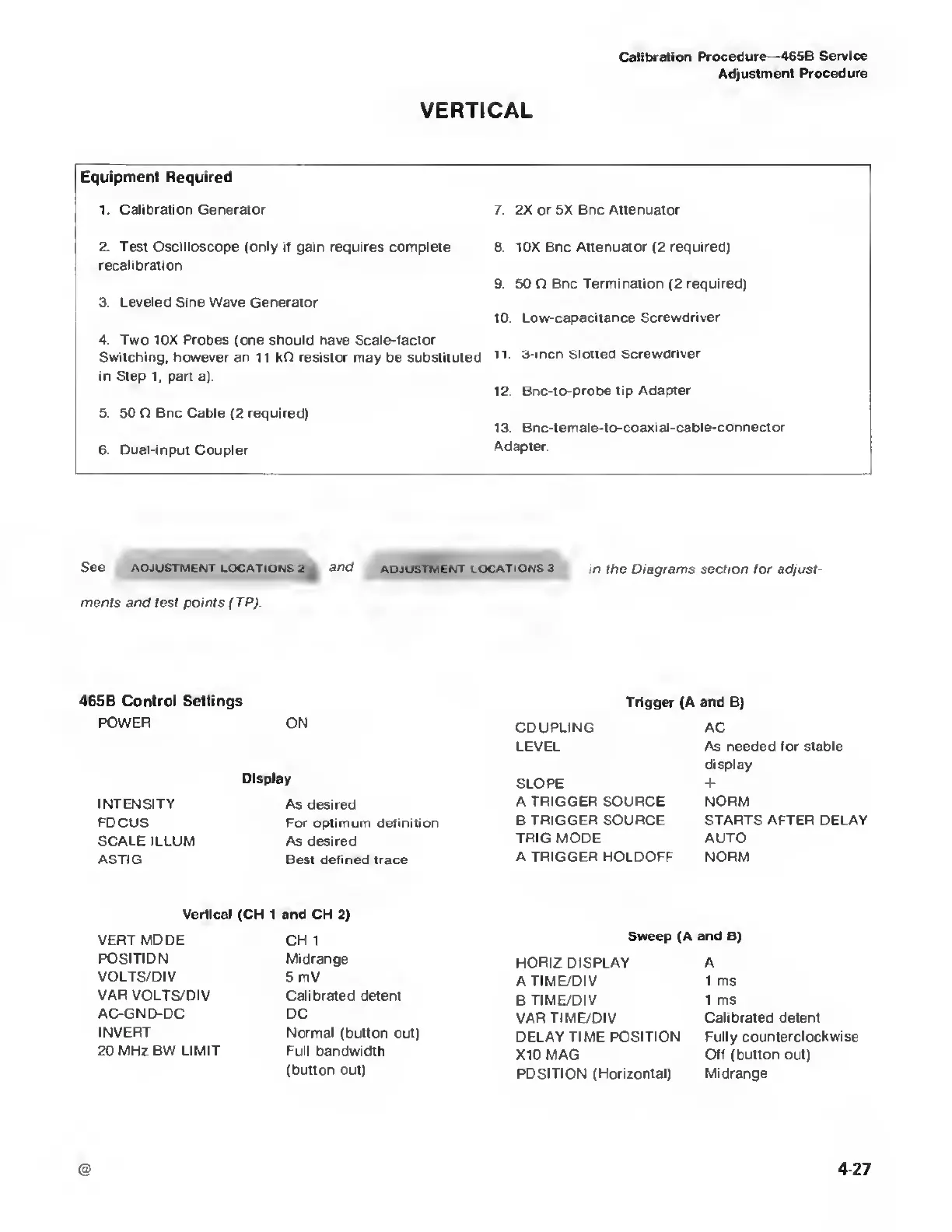

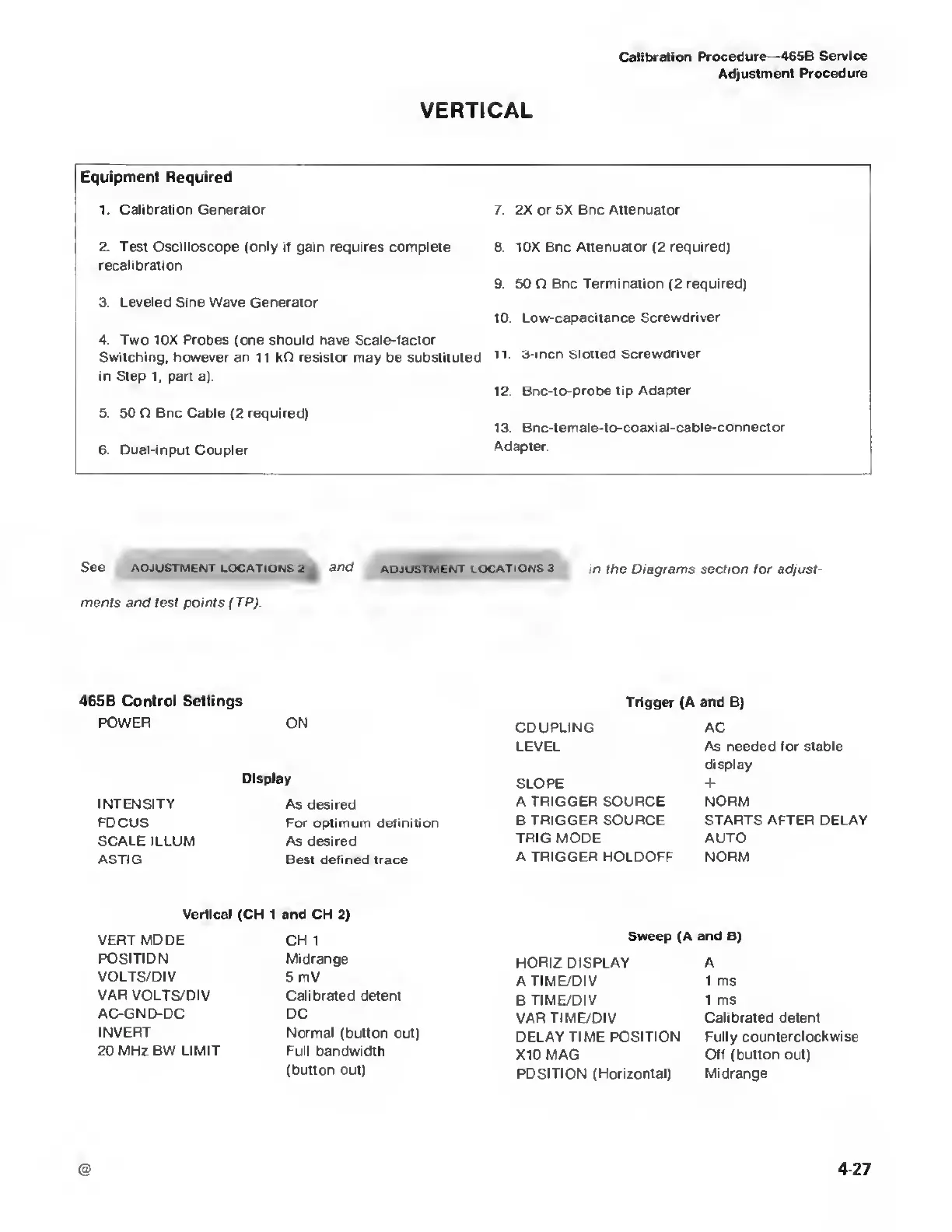

Calibration Procedure

—

465B

Service

Adjustment Procedure

VERTICAL

Equipment Required

1 Calibration Generator

7. 2X or 5X Bnc Attenuator

2. Test Oscilloscope (only if gain requires complete

8

10X Bnc Attenuator

(2

required)

recalibration

9.

50

0 Bnc Termination

(2

required)

3. Leveled Sine Wave Generator

10.

Low-capacitance Screwdriver

4 Two 10X Probes

(one

should

have Scale-factor

Switching, however an 11 kO resistor

may

be substituted

in Step

1,

part

a).

n.

3-incn slotted Screwdriver

12. Bnc-to-probe tip

Adapter

5.

50

fi Bnc

Cable

(2

required)

13.

Bnc-female-to-coaxial-cable-connector

6. Dual-input Coupler

Adapter

See

ADJUSTMENT locations

2

and

ADJUSTMENT

locations

3

in the Diagrams section for ad/ust-

ments and test

points (TP).

465B

Control

Settings Trigger

(A

and B)

POWER ON

COUPLING AC

LEVEL As needed for stable

display

Display

SLOPE

+

INTENSITY

As desired

A TRIGGER SOURCE NORM

FOCUS For optimum definition

B

TRIGGER SOURCE STARTS AFTER DELAY

SCALE ILLUM As desired

TRIG MODE AUTO

ASTIG Best defined trace

A TRIGGER HOLDOFF NORM

Vertical (CH 1 and CH

2)

VERT

MODE CH 1

Sweep (A

and

B)

POSITION

Midrange

HORIZ DISPLAY A

VOLTS/DI V 5 mV

A

TIME/DIV 1 ms

VAR VOLTS/DIV Calibrated detent

B TIME/DIV

1 ms

AC-GND-DC DC

VAR TIME/DIV

Calibrated detent

INVERT Normal

(button out)

DELAY TIME POSITION Fully

counterclockwise

20 MHz BW LIMIT Full bandwidth

X10 MAG Off

(button out)

(button out)

POSITION (Horizontal) Midrange

427

Loading...

Loading...