Cali bration-AA

501

INTERNAL ADJUSTMENT PROCEDURE

l

nfroduction

This procedure should be performed if the instrument

fails to meet the performance requirements of the elec-

trical characteristics listed in the Specification section of

this manual. To insurecontinued instrument accuracy it is

recommended that adjustment be performed every 1000

hours of operation or every six to twelve months

if

used

infrequently. Adjustment is also recommended following

instrument repair or modification. Adjustments must be

made at an ambient temperature of

+20°C to +30°C.

Services Available

If other test equipment is substituted, the calibration

setup may need to be altered to meet the requirements of

the equipment used.

Adjustment Access

Use an extender cable (Tektronix Part No. 067-0645-

02) to operate the plug-in outside the power module.

Remove t he top and both side covers oft he AA 501 to gain

access to the adjustments. All adjustments on the Input

board are accessed from the

topof theinstrument. See the

Adjustment Location illustration in the pullout pages at

the back of this manual.

Tektronix, Inc. provides complete instrument repair

and adjustment at

local field service centers and at the

1.

Adjust Amp Offset

factory service center. Contact your local Tektronix Field

Office or representative for further information.

a. Press the FUNCTION LEVEL and VOLTS

pushbut-

tons.

Test

Equipment Required

b. Set the INPUT LEVEL RANGE switch tothe200

pV

The test equipment (or equivalent) listed inTable4-1 is

position.

required for adjustment of the AA 501. Specifications

given for the test equipment are the minimum necessary

for accurate adjustment. All test equipment is assumed to

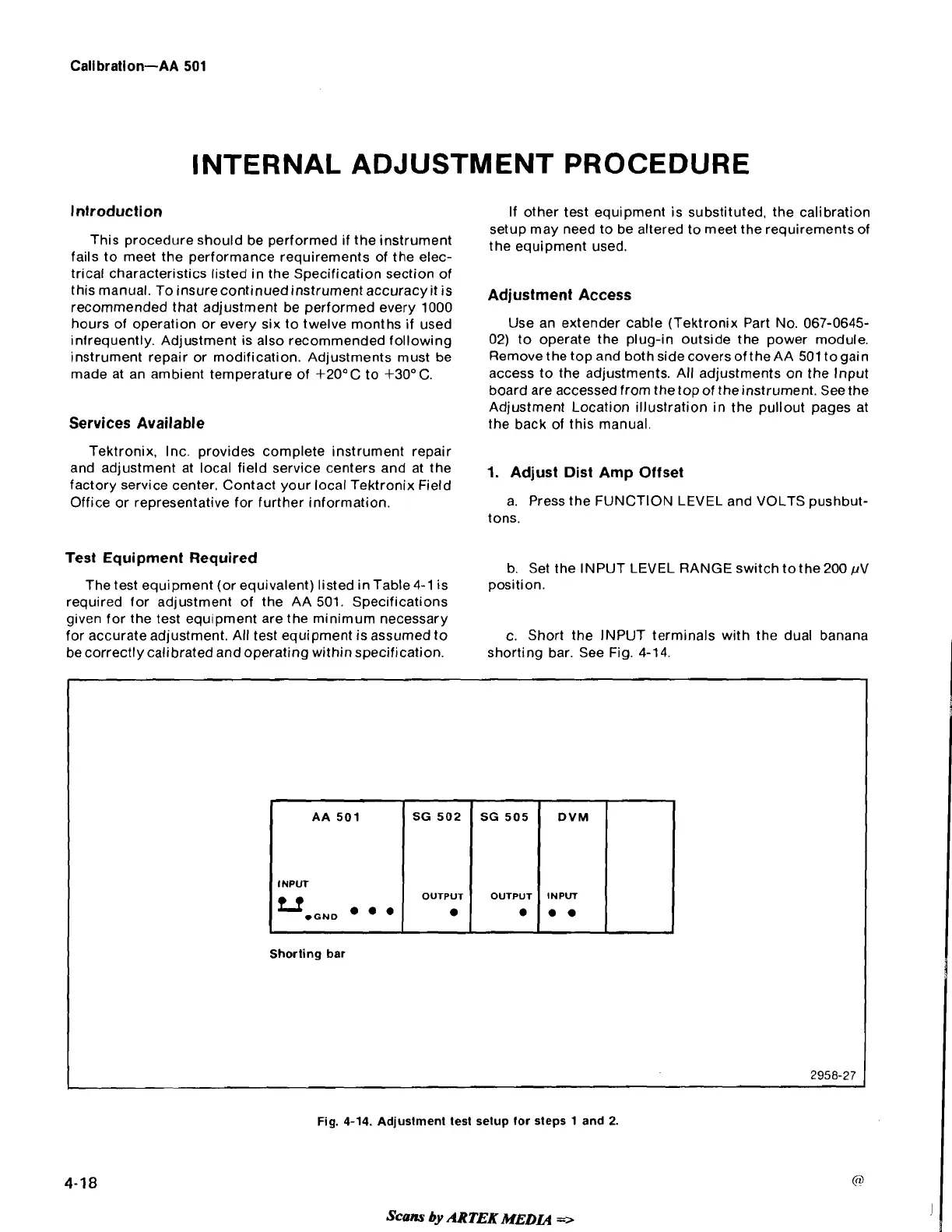

c.

Short the INPUT terminals with the dual banana

be correctly calibrated and operating within specification. shorting bar. See Fig. 4-14.

Shorting

bar

Fig.

4-14.

Adjustment test setup for steps 1 and

2.

scam

by

ARTEK

MEDL4

=a

Loading...

Loading...