Section

5-AA 501

MAINTENANCE

GENERAL MAINTENANCE INFORMATION

Static-Sensitive Components

9.

Use a soldering iron that is connected to earth

ground.

CAUTION

EX2

10. Use only special antistatic suction type or wicktype

Static discharge can damage any semiconductor

desoldering tools.

component in this instrument.

This instrument contains electrical components that

are susceptible to damage from static discharge. See

Table 5-1 for relative susceptibility of various classes of

semiconductors. Static voltages of 1

kV to 30 kV are

common in unprotected environments.

Observe the following precautions to avoid damage:

1. Minimize handling of static-sensitive components.

2.

Transport and store static-sensitive components or

assemblies in their original containers, on a metal rail, or

on conductive foam. Label any package that contains

static-sensitive assemblies or components.

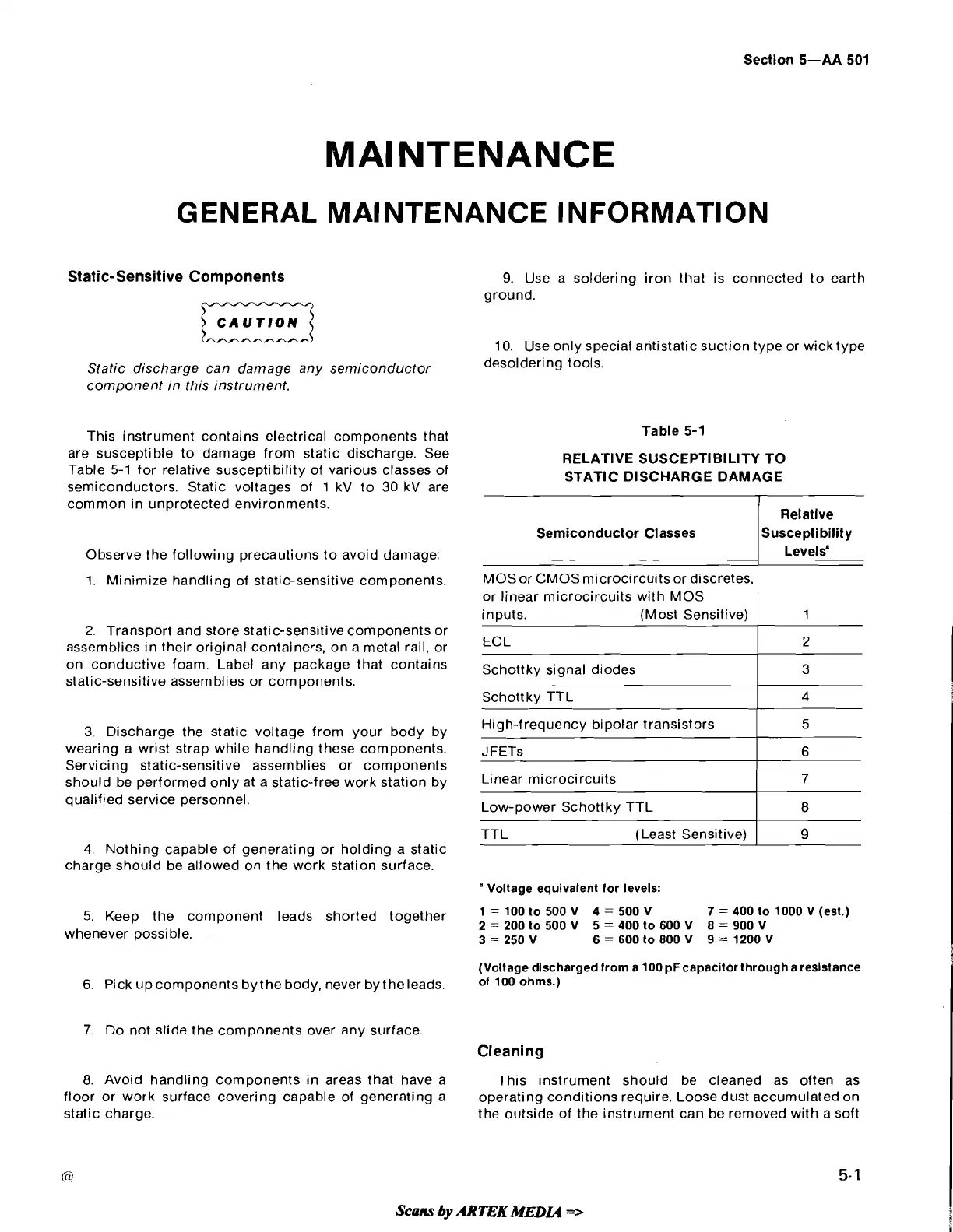

Table

5-1

RELATIVE SUSCEPTIBILITY TO

STATIC DISCHARGE DAMAGE

MOS or CMOS microcircuits or discretes.

or linear microcircuits with MOS

inputs. (Most Sensitive)

Semiconductor Classes

Relative

Susceptibility

Levels'

schottky

TTL

14

ECL

Schottky signal diodes

2

3

3. Discharge the static voltage from your body by

High-f requency bipolar transistors

wearing a wrist strap while handling these components.

JFETS

Servicina static-sensitive assemblies or comDonents

5

6

should be performed only at a static-free work station by

Linear microcircuits

qualified service personnel.

Low-power Schottky TTL

a

Voltage equivalent for levels:

7

8

I

5. Keep the component leads shorted together

=

loo

500

=

500

7

=

400 to 1000 V (est.)

2

=

200 to 500 V 5

=

400 to 600 V 8

=

900 V

whenever possible.

3

=

250 V

6

=

600 to 800 V 9

=

1200 V

TTL (Least Sensitive)

(Voltage discharged from a 100 pFcapacitor through a resistance

6.

Pick up components by the body, never by the leads.

Of

100 ohms.)

9

7.

Do not slide the components over any surface.

Cleaning

4.

Nothing capable of generating or holding a static

charge should be allowed on the work station surface.

8.

Avoid handling components in areas that have a This instrument should be cleaned as often as

floor or work surface covering capable of generating a

operating conditions require. Loose dust accumulated on

static charge. the outside of the instrument can be removed with a soft

Scans

by

ARTEK

MEDLQ

*

Loading...

Loading...