8-S7

L3130 · L3430 · L3830 · L4630 · L5030, WSM

HYDRAULIC SYSTEM

Hydraulic Flow Test (Continued)

[L3130, L3430, L3830]

[L4630, L5030]

W1013113

(2) Disassembling and Assembling

• The hydraulic pump is precision machined and assembled : if disassemble once, it may be unable to

maintain its original performance. Therefore, when the hydraulic pump fails, replacement should be

carried out with the hydraulic pump assembled except when emergency repair is unavoidable.

• When repair is required, follow the disassembly and servicing procedures shown below with utmost care.

• Be sure to test the hydraulic pump with a flowmeter before disassembling.

• After reassembly, be sure to perform break-in operation and ensure that there is nothing abnormal with

the hydraulic pump.

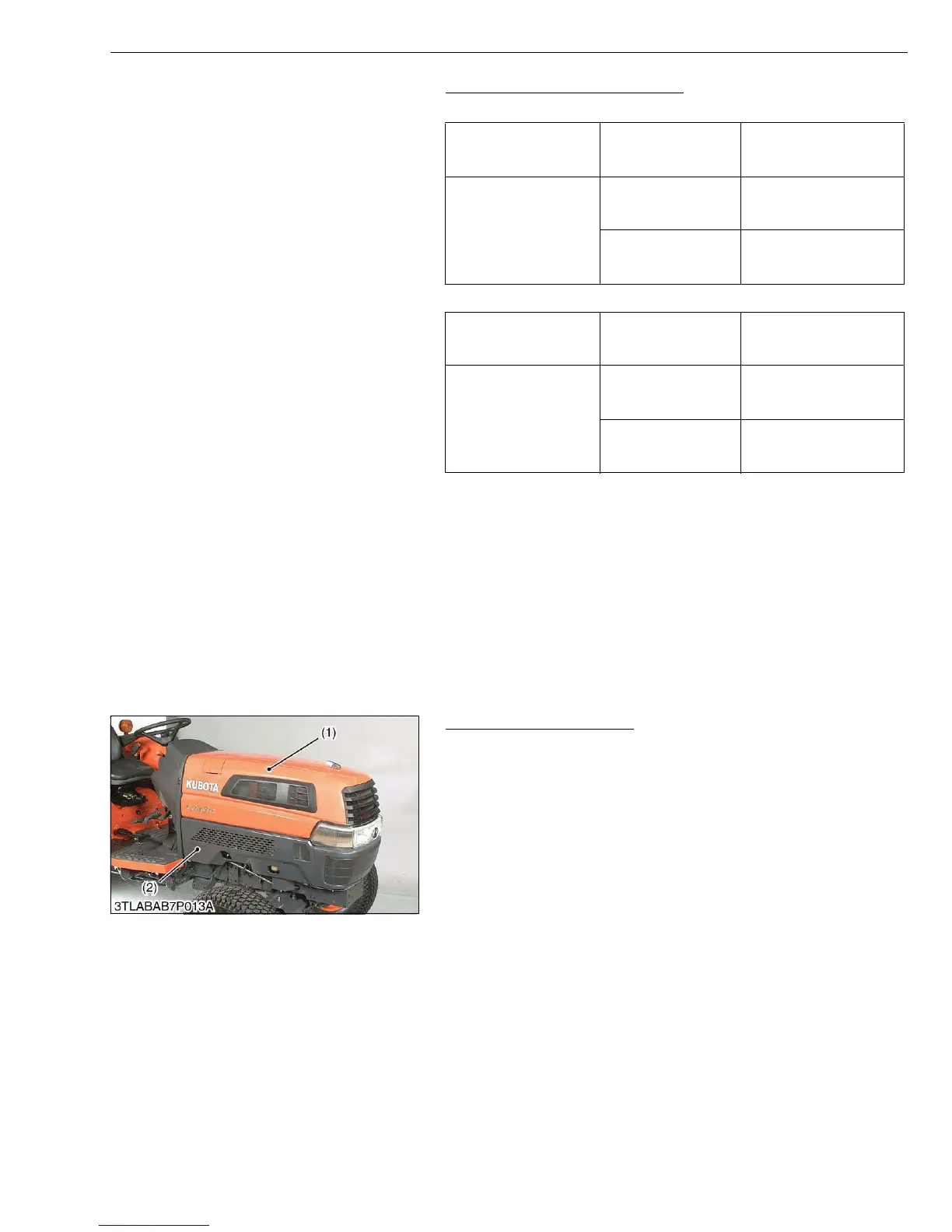

(A) Removing Hydraulic Pump Assembly

Bonnet and Side Skirt RH

1. Open the bonnet (1).

2. Remove the side skirt RH (2).

W1014408

Hydraulic pump delivery

at no pressure

Factory spec.

Above 31.5 L/min.

8.32 U.S.gals/min.

6.93 Imp.gals/min.

Hydraulic pump delivery

at rated pressure

Factory spec.

Above 30.9 L/min.

8.16 U.S.gals/min.

6.80 Imp.gals/min.

Allowable limit

27.6 L/min.

7.29 U.S.gals/min.

6.07 Imp.gals/min.

Hydraulic pump delivery

at no pressure

Factory spec.

Above 37.0 L/min.

9.78 U.S.gals/min.

8.14 Imp.gals/min.

Hydraulic pump delivery

at rated pressure

Factory spec.

Above 36.3 L/min.

9.59 U.S.gals/min.

7.99 Imp.gals/min.

Allowable limit

32.4 L/min.

8.56 U.S.gals/min.

7.13 Imp.gals/min.

(1) Bonnet (2) Side Skirt RH

Loading...

Loading...