JOHNSON CONTROLS

167

SECTION 8 – UNIT OPERATION

FORM 150.67-NM2

ISSUE DATE: 01/31/2019

8

PROGRAMMING YCAL0019-0028

Condenser fan control type must be programmed un-

der both the OPTIONS and PROGRAM keys when a

VFD is installed on the chiller. Under the OPTIONS

key, FAN CONTROL must be programmed for DIS-

CHARGE PRESSURE CONTROL only. This will as-

sure condenser fan control of the chiller is solely by

discharge pressure, with no ambient control.

Under the PROGRAM Key, the FAN CONTROL

ON PRESSURE should be programmed for 385

PSIG and the FAN DIFFERENTIAL OFF PRES-

SURE must be programmed for 125 PSIG.

Programming as suggested assures the chiller control

points for the second fan in the fan staging sequence

and the inverter control points are matched for opti-

mum control of the fans at reduced ambient tempera-

tures, assuring superheat and oil control is not compro-

mised. When the chiller and VFD fan control points are

programmed properly, the fans will operate as outlined

in Table 26 on page 167.

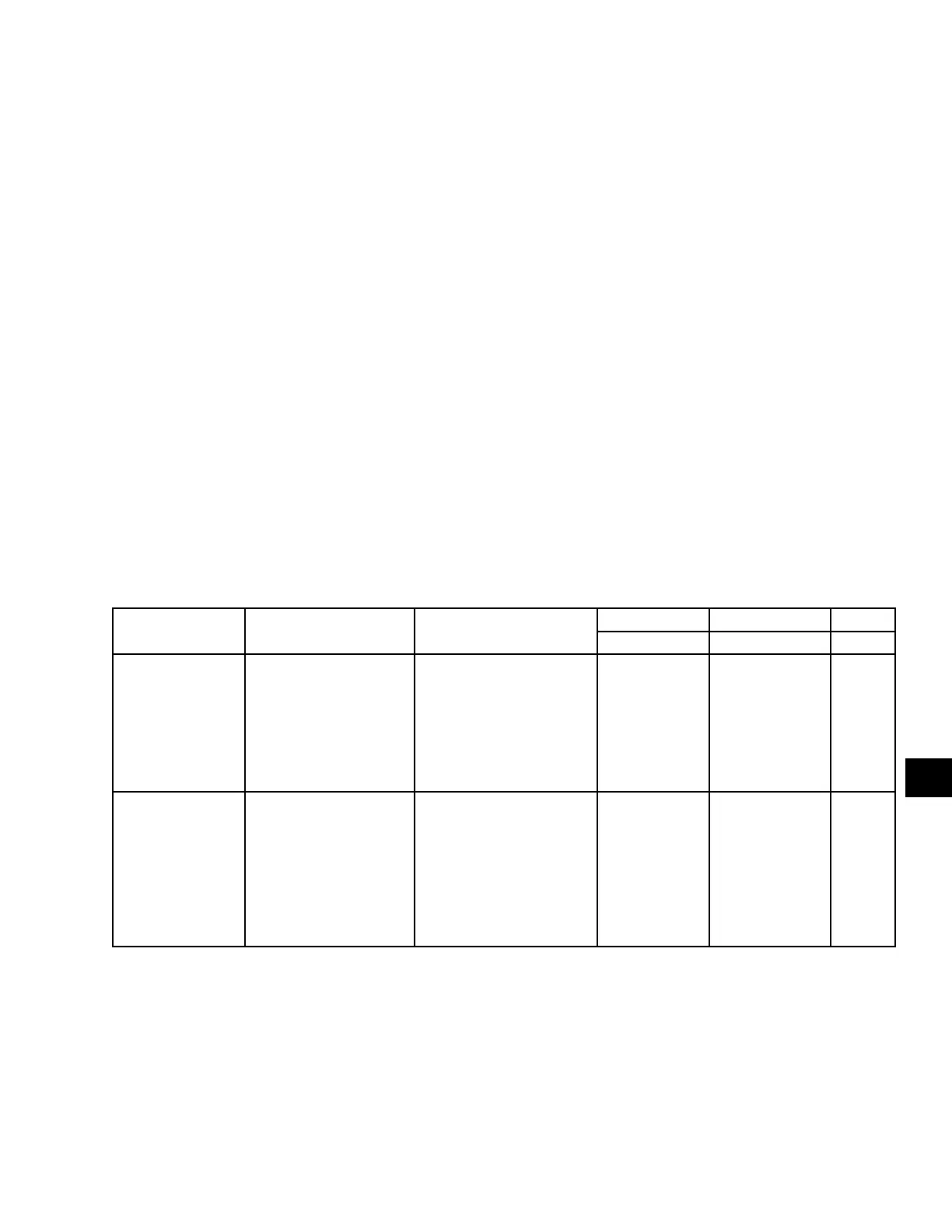

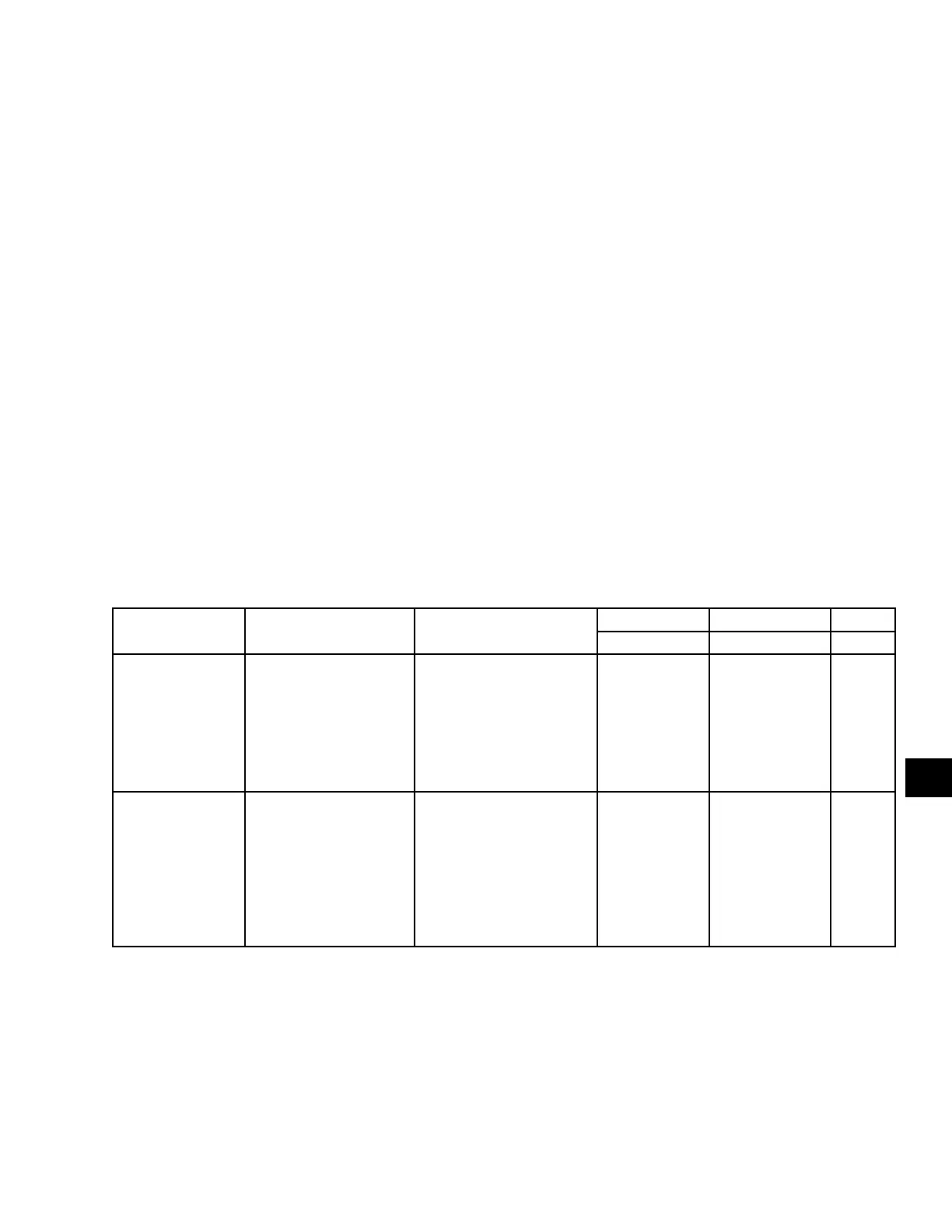

TABLE 26 - YCAL0019 – 0028 VFD LOW AMBIENT OPTION – CONDENSER FAN CONTROL OPERATION

FAN STAGE ON OFF

CONTACTOR MICROBOARD FAN #

SYS 1 SYS 1 SYS 1

1:

VFD Control

(1 fan

Variable Speed)

Fan Speed Is A Function

Of Liquid Temperature

Fan will turn on when

liquid line temperature is

above 65º F.

Speed increases with

temperature

FAN Will Turn OFF When

Liquid Temperature Drops

Below 65 °F

7M TB7-3 1

2:

1 Fan VFD

Control

2nd Fan Full

Speed Under

Contactor Control

385 PSIG, Both Fans

Will Be Running Full

Speed

Discharge Pressure

< 260 PSIG (Pressure Is

< Fan Control ON Pressure

of 385 PSIG Minus Fan

Differential

Pressure of 125 PSIG =

260 PSIG) Fan 1 Will Still

Be Running

7M & 8M

TB7- 3

&

TB7-10

1 & 3

Loading...

Loading...