JOHNSON CONTROLS

101

SECTION 6 - OPERATION

FORM 201.30-ICOM1 (519)

ISSUE DATE: 05/22/2019

6

MESSAGE DESCRIPTION

YYYYYYY HPCO

Hardware-Initiated Fault - The mechanical High Pressure Cutout (HPCO) protects the system

from experiencing dangerously high discharge pressure. A system will fault and shut down

immediately when the mechanical high pressure cutout contacts open. The fault will occur

immediately and not wait three seconds. The HPCO is wired in series with the VSD run signal

and will only be checked by the control board when the system is running.

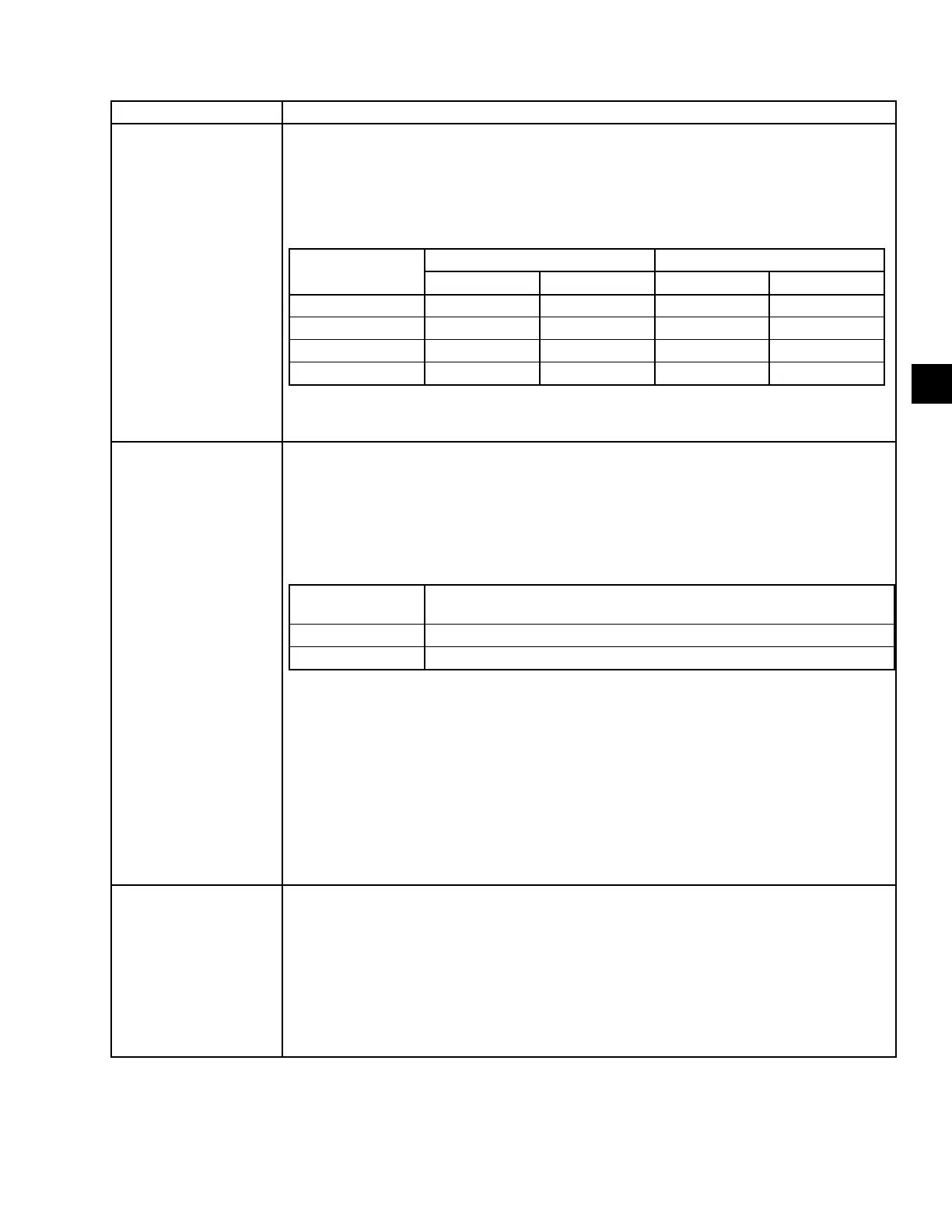

TABLE 34 - HPCO MECHANICAL CUTOUTS

HPCO

DESCRIPTION

OPEN CLOSE

PSIG (MPa) + / - PSIG (MPa) + / -

025-39956-001 337 (2.32) 8 (0.05) 230 (1.58) 10 (0.07)

025-39956-002 299 (2.06) 7 (0.05) 200 (1.37) 10 (0.07)

025-39956-003 341 (2.35) 7 (0.05) 200 (1.37) 10 (0.07)

025-39956-004 204 (1.40) 7 (0.05) 120 (0.82) 10 (0.07)

YYYYYYY will show FAULT to indicate a system is in a FAULT condition, and will restart when

the 120 second anti-recycle timer times out; or will show LOCKOUT, and the system will not

restart until the operator clears the fault using the keypad.

YYYYYYY LOW DIFF

OIL PRESSURE

This fault protects the compressor from low oil ow causing insufcient lubrication. A system

will fault and shut down with a ramped shutdown when its differential between oil and suction

pressure falls below the fault. The safety is ignored for the rst 60 seconds of run time. If restart

transition has occurred, the timer is set according to Table 35 on page 101 with a maximum limit

of 73 seconds. The timer calculation allows for 60 seconds of run time after the time it takes to

ramp the running compressor from its existing speed to shutdown speed.

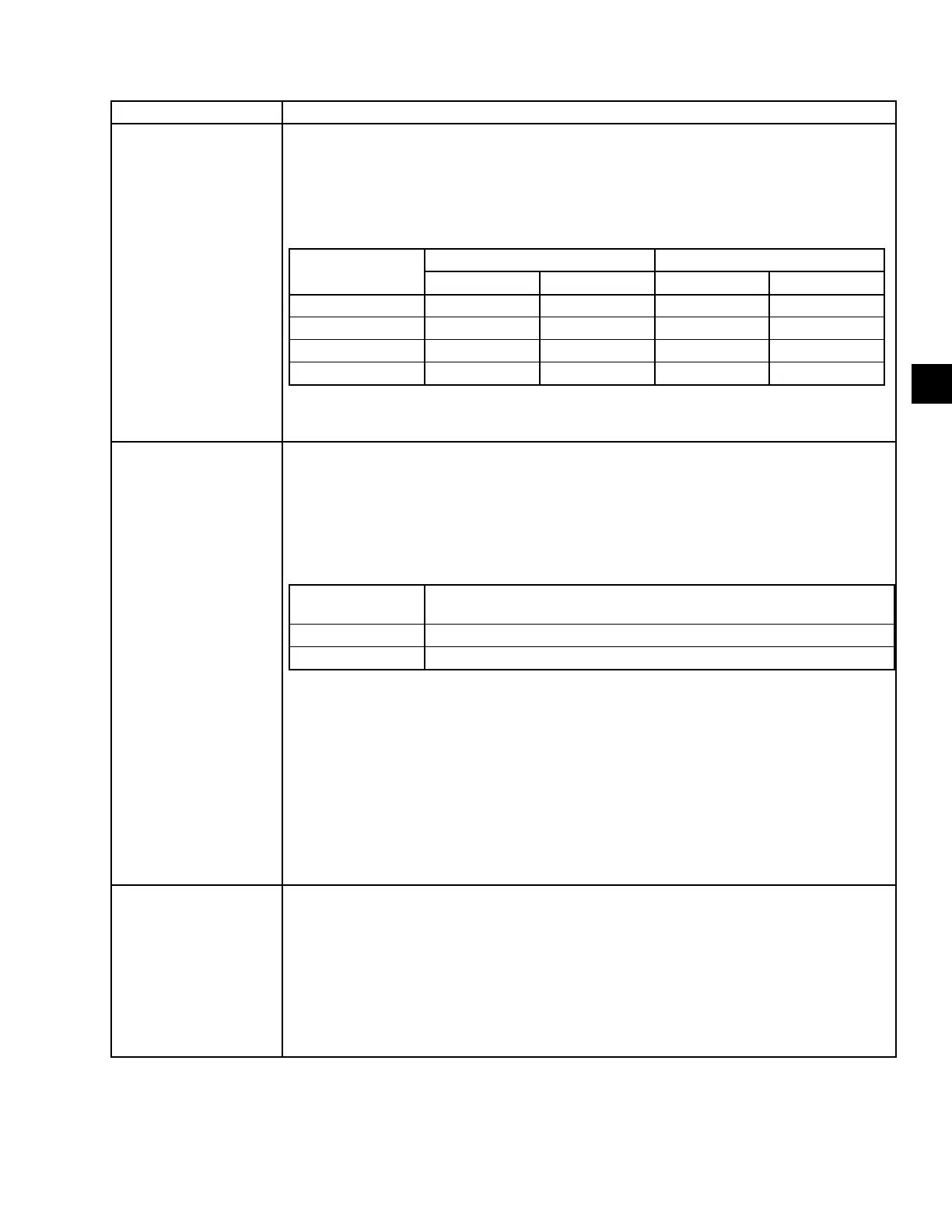

TABLE 35 - TIMER SETTINGS

CURRENT

FREQUENCY

INCREASE TIMER BY:

>100 Hz 60 sec. + (100 Hz - 5 Hz)/30.4 Hz/sec + 9.5 sec.

< or = 100 Hz 60 sec. + (Current freq - 5 Hz)/10 Hz/sec

NOTE: 9.5 sec = (100 Hz-5 Hz/10 Hz sec), the time it takes to ramp from 100 Hz to 5 Hz.

After the timer expires, the fault is linearly ramped from 0 psid (0 kPa) to the programmable

threshold (20-60 psid, default 25 psid (137-413 kPa, default 172 kPa) in 10 minutes. If the VSD

frequency is less than 50 Hz when the differential pressure falls below the limit, the three second

start-up bypass time will be increased to 30 seconds. Under these conditions, the slow speed

of the running compressor causes the oil differential to become very low, especially if the water

temperature and the suction pressure are high. The bypass make sure the compressor will not

trip on a nuisance low oil differential fault. This auto-restart safety will lock out on the third fault

in 90 minutes. YYYYYYY will show FAULT to indicate a system is in a FAULT condition, and will

restart when the 120 second anti-recycle timer times out; or will show LOCKOUT, and the system

will not restart until the operator clears the fault using the keypad.

YYYYYYY LOW

DISCHARGE

SUPERHEAT

This fault protects against excessive liquid refrigerant carryover from the evaporator, in cases

which may be a result of overcharge of refrigerant or another refrigerant inventory problem. It

also protects the compressor from liquid refrigerant ooding back from the economizer feed line,

in cases where the economizer valve fails to close. This safety is ignored for the rst 10 minutes

of system run time. If the discharge superheat falls below 5.0°F (2.8°C) for ten minutes, the

system will shutdown. This fault causes a lockout on the third fault in 90 minutes. YYYYYYY will

show FAULT to indicate a FAULT condition, and will restart when the 120 second anti-recycle

timer times out; or will show LOCKOUT, and the system will not restart until the operator clears

the fault using the keypad.

TABLE 33 - SYSTEM SAFETIES FAULTS (CONT'D)

Loading...

Loading...