JOHNSON CONTROLS

131

FORM 201.30-ICOM1 (519)

ISSUE DATE: 05/22/2019

7

SECTION 7 - MAINTENANCE

GENERAL REQUIREMENTS

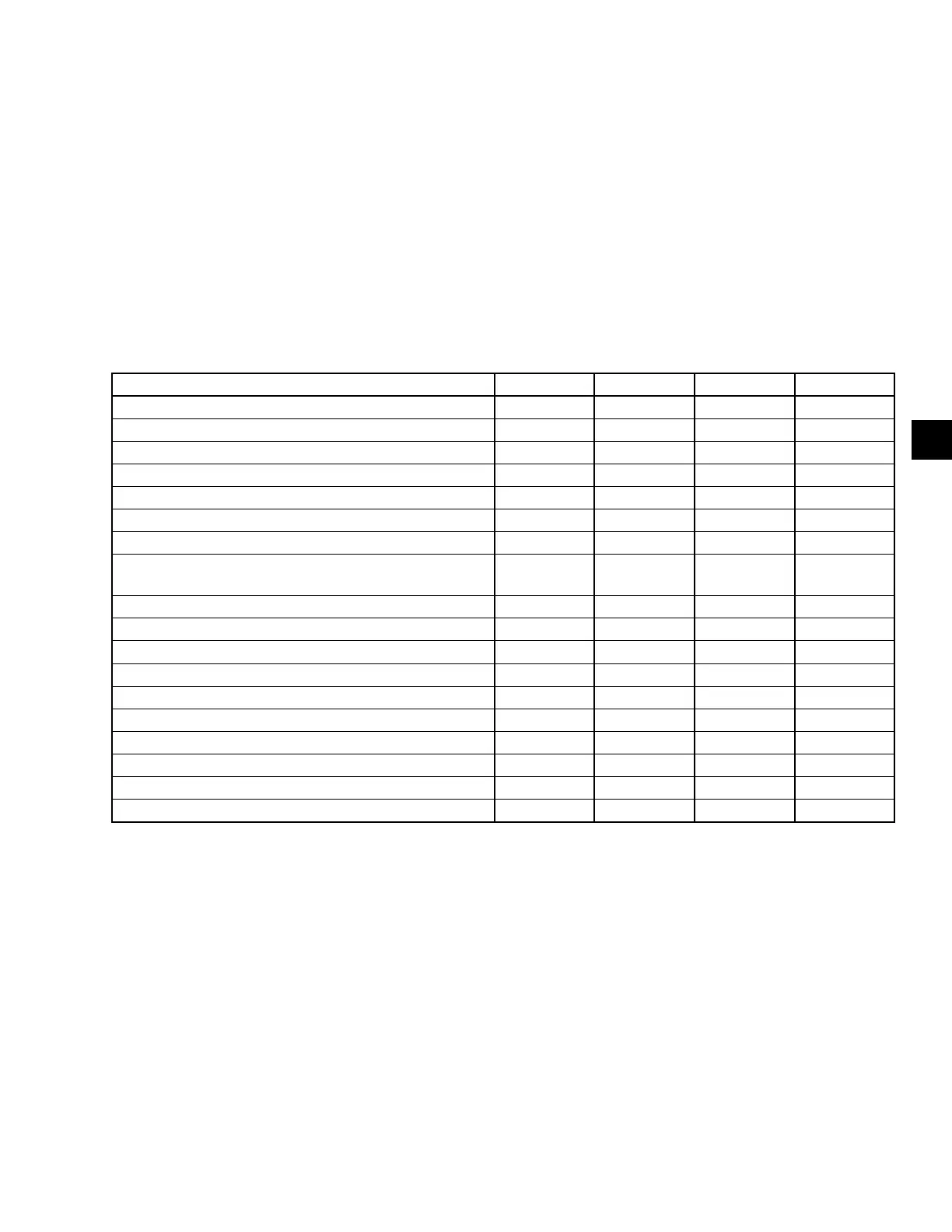

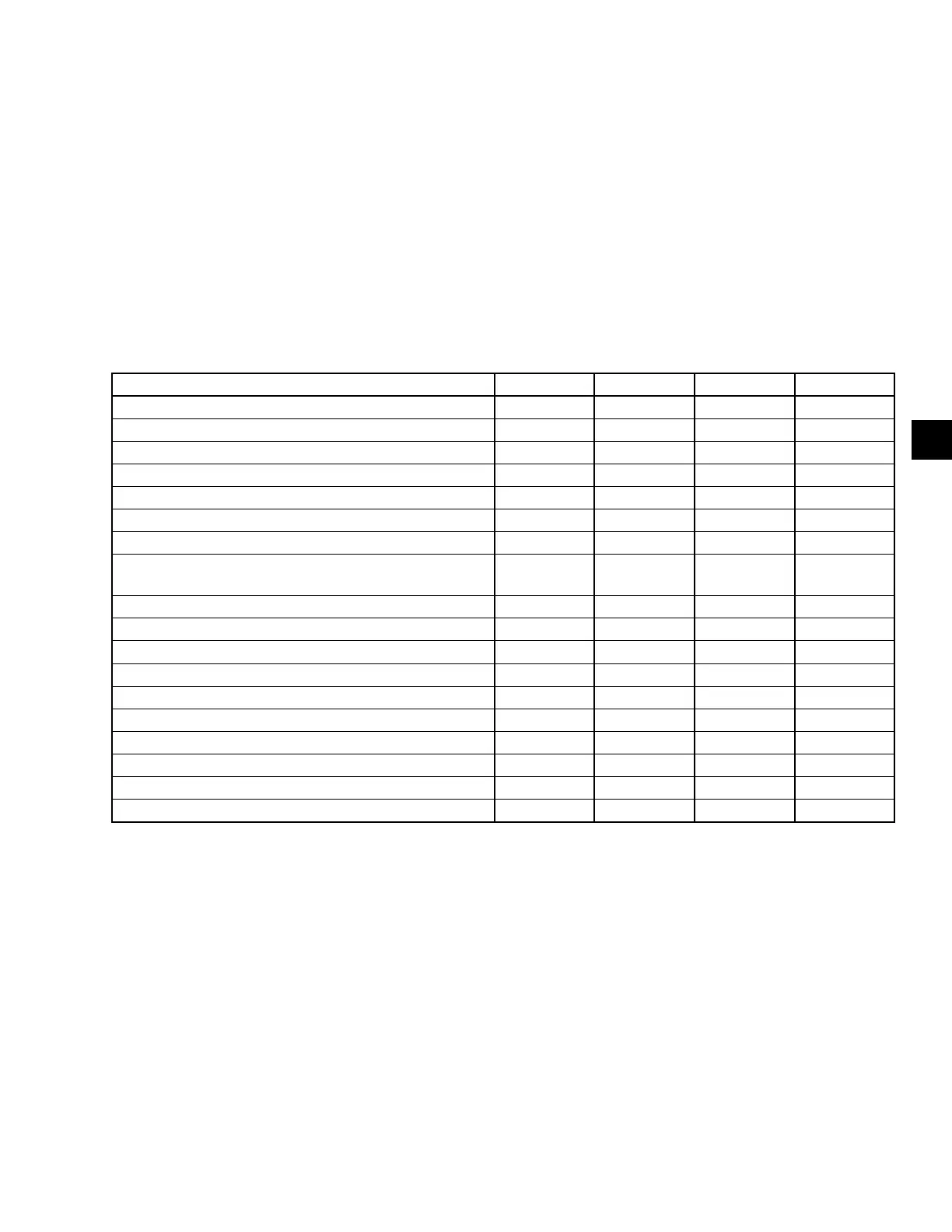

The maintenance requirements for YVWA chillers are

shown below. The procedure is in the left-hand column

and the required frequency is marked with an X in the

right-hand column. Refer to the notes at the bottom of

the table to maintain warranty validation.

TABLE 43 - OPERATION/INSPECTION /MAINTENANCE REQUIREMENTS FOR YVWA CHILLERS

PROCEDURE DAILY WEEKLY MONTHLY ANNUALLY

Record operating conditions (on applicable log form) X

Check oil level in oil level sight glass X

Check refrigerant levels X

Check oil return system operation X

Check operation of motor starter X

Check oil heater operation X

Check 3-phase voltage and current balance X

Check programmable operating setpoints and safety

cutouts. Make sure they are correct for the application.

X

Verify condenser and evaporator liquid ows X

Check and repair leaks as needed¹ X

Check and tighten all electrical connections X

Check the motor windings resistance X

Clean or back ush VSD heat exchanger X¹

Replace VSD coolant (after cleaning heat exchanger) X

Perform oil analysis on compressor lube oil X¹

Perform refrigerant analysis X

Perform Eddy current testing and inspect tubes X²

Clean evaporator and condenser tubes X²

For operating and maintenance requirements listed above, refer to appropriate service literature, or contact a local Johnson Controls Field

Service Ofce.

¹ This procedure must be performed at the specied time interval by an industry certied technician, who has been trained and qualied to

work on this type of YORK equipment. A record of this procedure being successfully carried out must be maintained on le by the equipment

owner should proof of adequate maintenance be required at a later date for warranty validation purposes.

² More frequent service may be required, depending on local operating conditions or relaxed with good engineering controls (water quality).

Compressor vibration analysis is not prescribed. Due

to the compressor design, a typical vibration analysis

can be misleading.

Periodic oil filter changes are not recommended.

Change the oil, filter, and filter driers only when an oil

analysis indicates a moisture issue.

Loading...

Loading...