JOHNSON CONTROLS

134

FORM 201.30-ICOM1 (519)

ISSUE DATE: 05/22/2019

SECTION 7 - MAINTENANCE

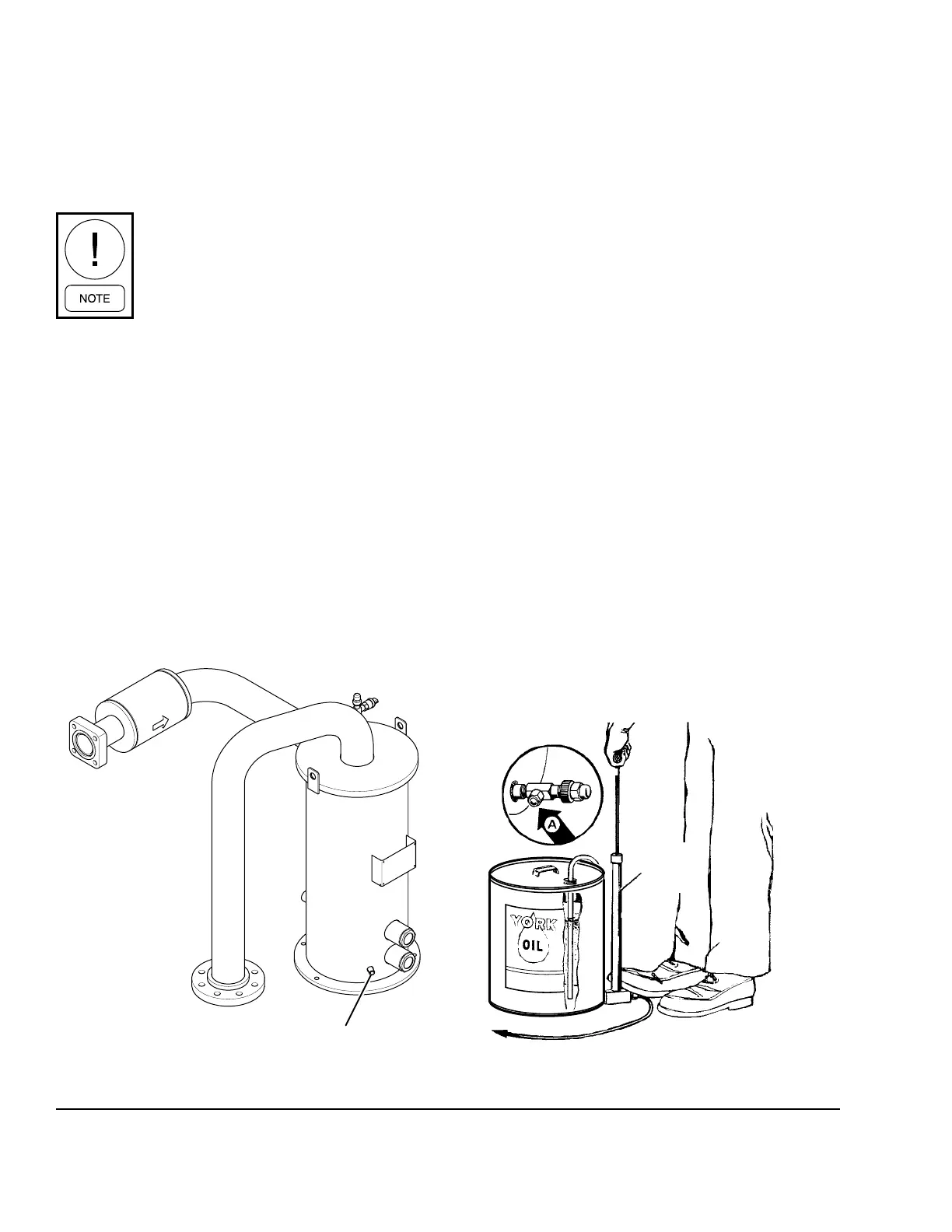

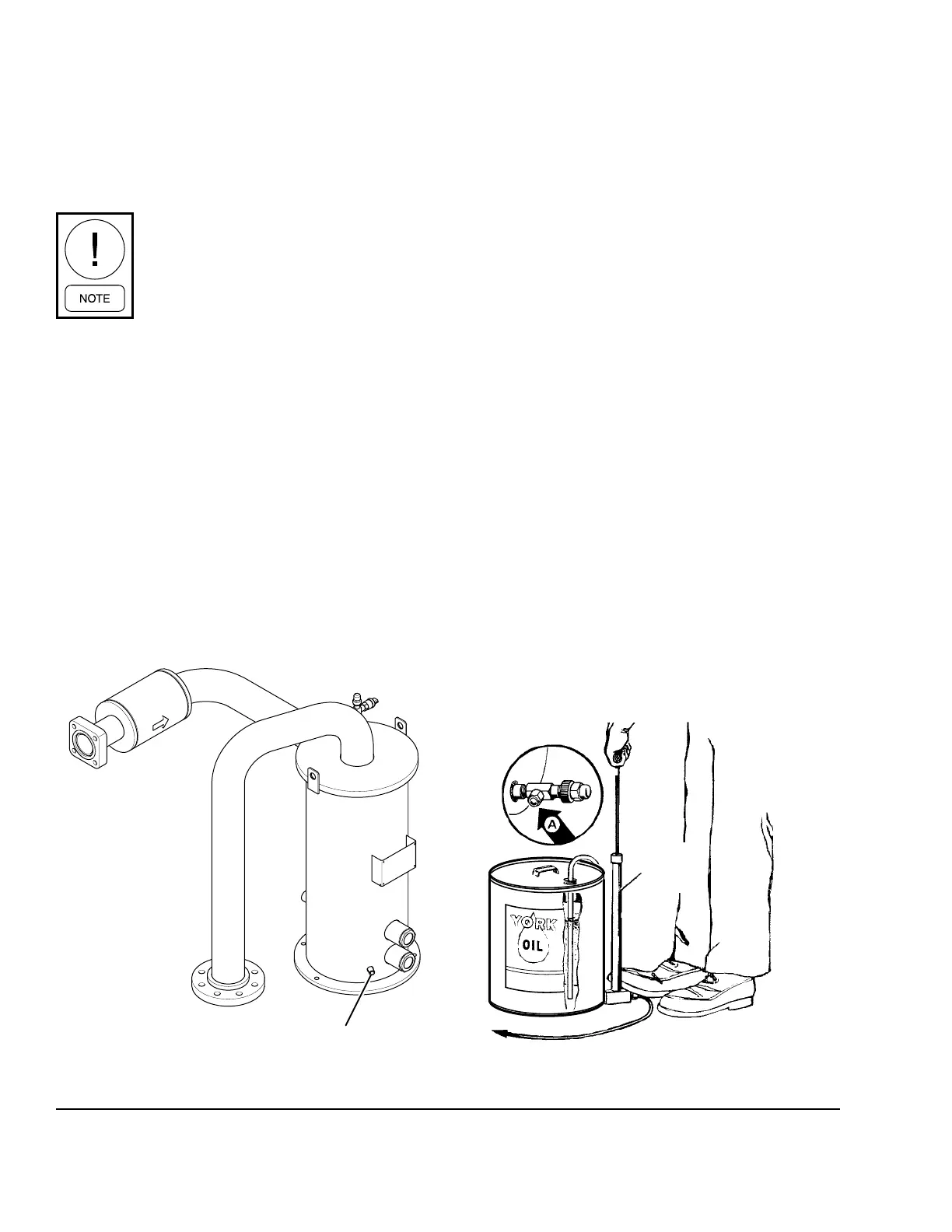

Adding Compressor Oil

Add the new YORK L oil into the oil separator with

the YORK oil charging pump (P/N 470-10654), and

proceed as follows :

1. Shut down the unit.

If adding oil restores the correct level, the

unit may keep operating.

2. Immerse the suction connection of the oil charg-

ing pump in a clean container of new oil. Connect

the pump discharge connection to the oil charging

valve. Do not tighten the connection at the valve

until after the air is forced out by pumping a few

strokes of the oil pump, which lls the lines with

oil and prevents air from being pumped into the

system as shown in Figure 64 on page 134.

3. Open the oil charging valve and pump oil into the

system until the oil level in the oil separator is

about midway in the upper sight glass, and then,

close the charging valve and disconnect the hand

oil pump as shown in Figure 64 on page 134.

4. As soon as oil charging is complete, close the

power supply to the VSD to energize the com-

pressor oil heater, which will keep the refrigerant

concentration in the oil to a minimum.

5. The compressor oil heater will maintain the oil

temperature below 160°F (71°C).

Oil Filter

A single oil filter, a replaceable 3-micron cartridge,

is provided in each compressor. Use only YORK ap-

proved oil filter elements.

The oil filter element should only be changed if a prob-

lem exists. Always replace the oil filter element and

O-ring together.

FIGURE 64 - CHARGING OIL

Oil

Charging Valve

Oil

Charging

Pump

Loading...

Loading...