JOHNSON CONTROLS

23

FORM 201.30-ICOM1 (519)

ISSUE DATE: 05/22/2019

3

Observe the following precautions:

• Notify the nearest Johnson Controls ofce in am-

ple time for a Johnson Controls representative to

observe rigging the unit to its operating position

and the assembly of its components. Refer to the

YVWA Installation Checklist (Form 201.30-CL1)

for detailed instructions. Do not dismantle or un-

wrap the chiller for any reason unless advised by

a Johnson Controls representative.

• Do not make nal power supply connections to

the compressor motor drive or control center.

• Do not open valves or connections under any cir-

cumstances.

• Do not charge the unit with refrigerant.

• Do not attempt to start the system.

• Do not run hot water (110°F/43°C max) or steam

through the evaporator or condenser at any time.

SHIPMENT AND STORAGE

To ensure consistent quality and maximum reliability,

all units are tested and inspected before leaving the fac-

tory. The chiller may be ordered and shipped in any of

the following forms:

• Form 1 (shipped assembled with refrigerant

charge)

• Form 2 (shipped assembled without refrigerant

charge)

• Form 7 (shipped in split assemblies without re-

frigerant)

• Miscellaneous loose items are shipped with all

forms.

When shipping a Form 2 or Form 7 unit,

make arrangements with the nearest

Johnson Controls Field Service Ofce to

make sure the refrigerant is on-site when

the unit is ready to be charged.

SECTION 3 - HANDLING, STORAGE, INSTALLATION AND REASSEMBLY

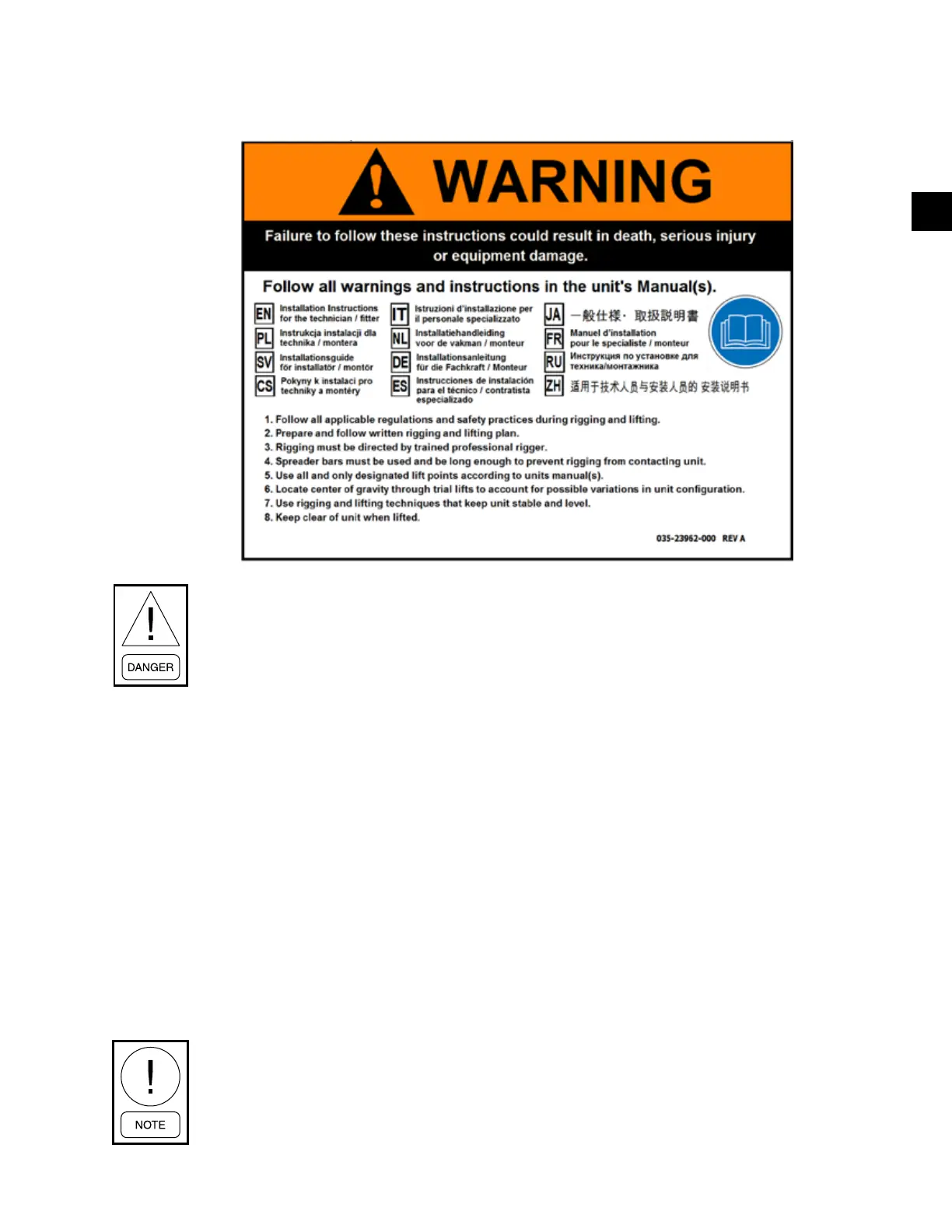

Rigging and lifting should only be done by a professional rigger in accordance with a written rig-

ging and lifting plan. The most appropriate rigging and lifting method will depend on job specic

factors, such as the rigging equipment available and site needs. Therefore, a professional rigger

must determine the rigging and lifting method to be used, and it is beyond the scope of this manual

to specify rigging and lifting details.

LD19197

Loading...

Loading...