JOHNSON CONTROLS

136

FORM 201.30-ICOM1 (519)

ISSUE DATE: 05/22/2019

SECTION 7 - MAINTENANCE

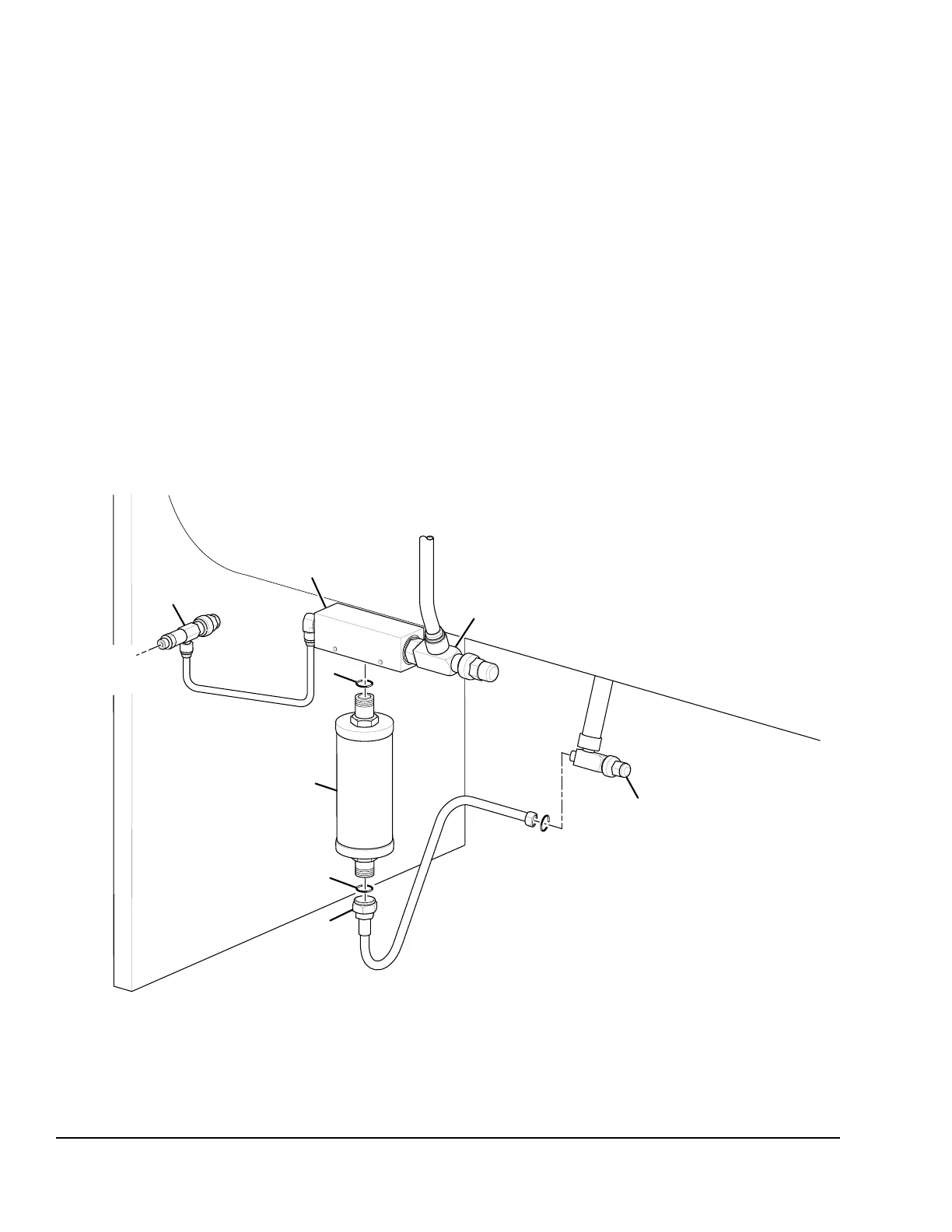

Replacing the Filter Drier

If the eductor flow seems restricted by high eductor

outlet temperatures or if the oil is replaced, replace the

filter using the following instructions to replace the

drier as shown in Figure 66 on page 136.

1. Power down the chiller.

2. Close all 3 service isolation valves (items 1).

3. Carefully remove any insulation on the lter drier

(item 2), located at the eductor block (item 3).

4. Relieve the pressure from the circuit into a suit-

able refrigerant recovery container. Filter drier

(item 2) contains a Schraeder valve for this pur-

pose.

5. Loosen the roto lock nut (item 4) at the piping end

of the lter drier (item 2).

6. Remove the lter drier from the eductor block and

discard lter drier and Teon seals (item 5).

7. Install the new Teon seals (items 5) and lter

drier (item 2).

8. Torque nuts (items 4) at each end of lter drier

(item 2) to 60 ft-lb (81 Nm), and replace the lter

drier insulation.

9. Evacuate the air from the lines to 500 microns.

10. Open all 3 service isolation valves (items 1).

11. Restore power to the chiller, the chiller is now

ready to be placed back into service.

LD16669A

1

5

2

5

4

1

1

3

FIGURE 66 - OIL EDUCTOR ASSEMBLY

TO

CONDENSER

TO

COMPRESSOR

Loading...

Loading...