JOHNSON CONTROLS

56

FORM 201.30-ICOM1 (519)

ISSUE DATE: 05/22/2019

SECTION 3 - HANDLING, STORAGE, INSTALLATION AND REASSEMBLY

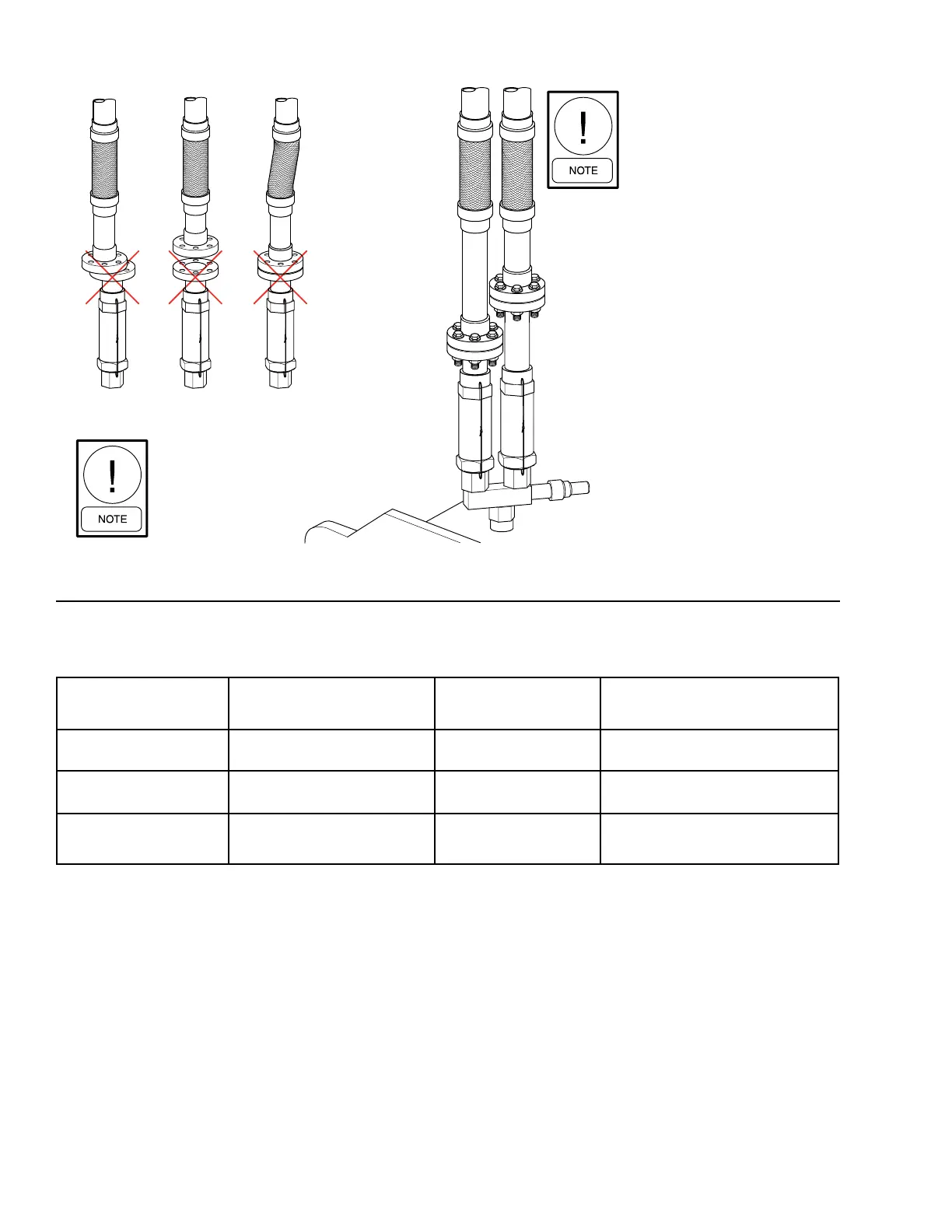

When installing relief piping there

must NOT be any piping strain.

Relief piping must be properly

aligned and supported to eliminate

any possible piping strain.

When installing relief piping an

ANSI flange or a piping union

must be used to make a

servicable piping connection.

Horizontal

Mis-aligned

Vertical

Offset

Compressed

LD16677

FIGURE 37 - TYPICAL COMPONENTS OF RELIEF PIPING

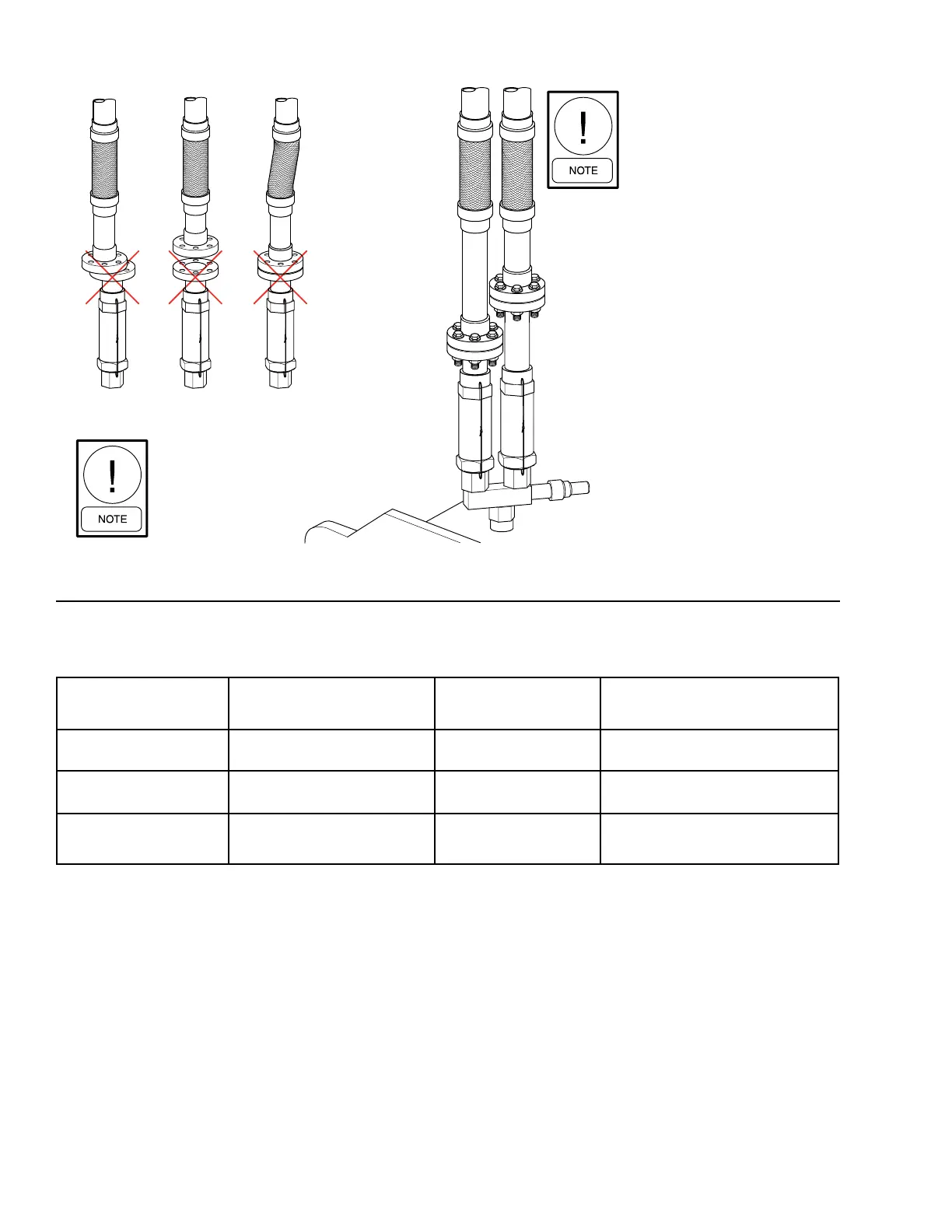

TABLE 19 - REFRIGERANT RELIEF CHARACTERISTICS (PER VALVE)

COMPONENT

DESIGN PRESSURE PSIG

(BAR)

AIR FLOW CAPACITY

LBS/MIN (KG/SEC)

OUTLET CONNECTION

EVAPORATOR

235

(16.2)

55.9 (0.423) 1” NPTF

CONDENSER

235

(16.2)

55.9 (0.423) 1” NPTF

CONDENSER

(HEAT PUMP OPTION)

388

(26.8)

90.3 (0.681) 1” NPTF

NOTES:

1. Dual relief valve consists of one three-way shut-off valve and two single relief valves. The valve conguration will not allow both valves to be

shut off at the same time, and valves are sized such that each relief valve has sufcient discharge capacity when used alone, which permits

safe removal of either relief valve for repair or replacement, while maintaining vessel protection.

2. Above information is for presssure vessels designed in accordancce with ASME Boiler and Pressure Vessel Code.

Loading...

Loading...