JOHNSON CONTROLS

50

FORM 201.30-ICOM1 (519)

ISSUE DATE: 05/22/2019

SECTION 3 - HANDLING, STORAGE, INSTALLATION AND REASSEMBLY

Assembly of O-ring Face Seal Fittings

The male end and female nut of face seal fittings have

UN/UNF straight threads. An elastomeric O-ring is fit-

ted into the grooved male end. During assembly, the O-

ring is firmly sandwiched between the sealing surfaces.

Sealing is thus affected and maintained by the O-ring

compression which results from the clamping force

generated by tightening the nut. The straight threads do

NOT offer sealing action; they provide the resistance

(holding power) for service pressure.

O-ring Face Seal Assembly

1. Inspect to ensure that both matching parts are free

of burrs, nicks, scratches or any foreign particles.

2. Install O-ring in grooved face seal end of tting,

if it is NOT pre-installed, use care NOT to nick

the O-ring.

3. Lubricate O-ring with a light coat of synthetic

Polyolester (POE) oil or POE grease.

4. Thread the nut by hand, and tighten nut to the ap-

propriate torque value shown in Table 14 on page

50 or Table 15 on page 51.

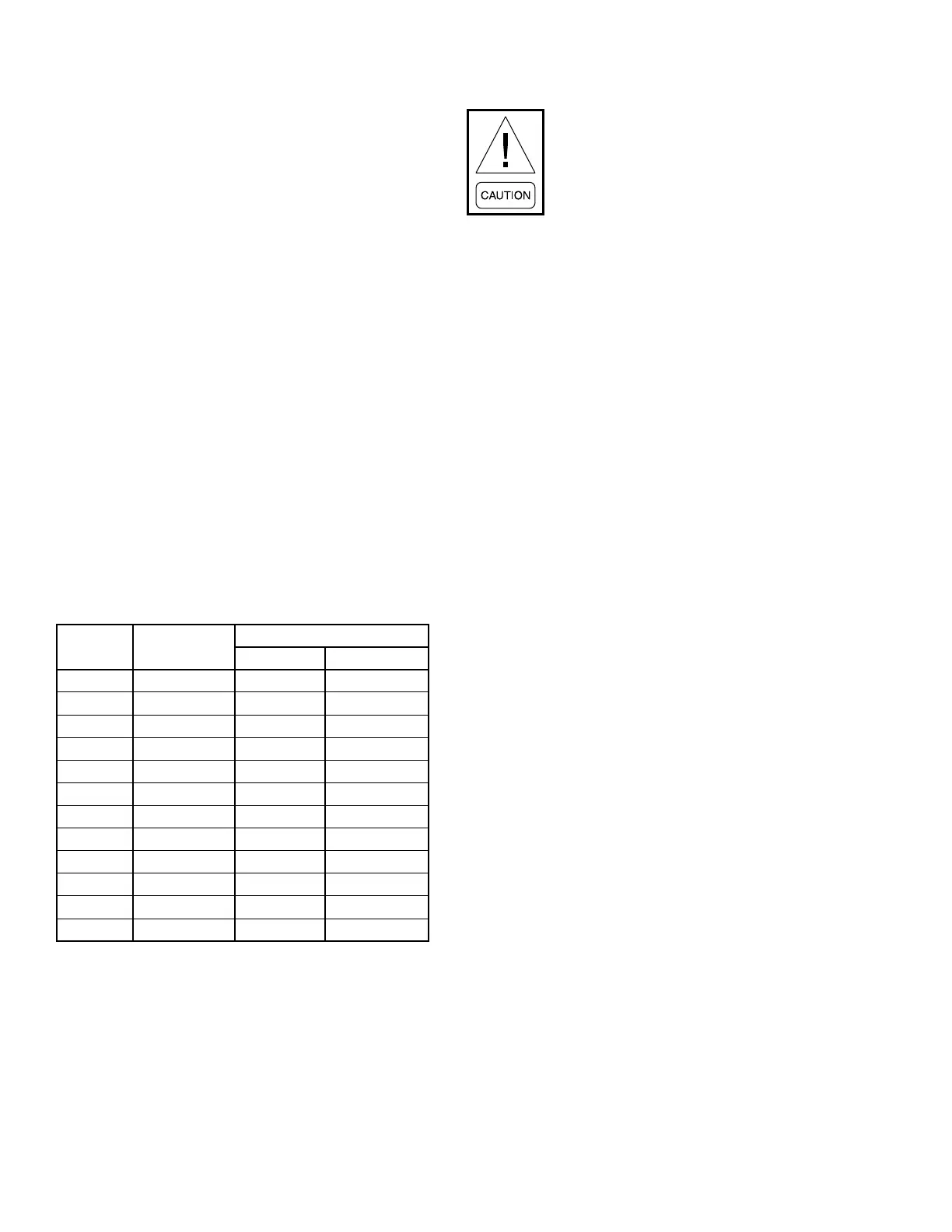

TABLE 14 - ASSEMBLY TORQUE METRIC FOR

METRIC TUBE FITTINGS

FITTING

SIZE

PORT

THREAD SIZE

TORQUE

FT-LB N-M

M10 M10 x 1 17 23

M12 M12 x1.5 24 33

M14 M14 x 1.5 34 46

M16 M16 x 1.5 46 63

M18 M18 x 1.5 61 83

M22 M22 x 1.5 94 127

M27 M27 x 2 139 189

M30 M30 x 2 167 226

M33 M33 x 2 194 263

M42 M42 x 2 265 359

M48 M48 x 2 302 410

M60 M60 x 2 359 487

BRAZED JOINTS

For personnel safety: No brazing or heat

working shall be done unless the refriger-

ant is removed and inert gas is installed

into the system.

Assembling Brazed Joints

Tubing ends shall be cut square to permit full inser-

tion into the female part of the joint, shall have circular

cross-section and shall be free of flat spots, dents, or

wrinkles. Fitting cups shall be circular cross-section

and free of flat spots. Joint insertion depth shall con-

form to dimensions shown in Table 16 on page 51

except for butt joints using filler metal suitable for a

butt joint.

Loading...

Loading...