220 ACS550 User’s Manual

Technical Data

Emergency Stop Devices

The overall design of the installation must include emergency stop devices and any

other safety equipment that may be needed. Pressing STOP on the drive’s control

panel does NOT:

• Generate an emergency stop of the motor.

• Separate the drive from dangerous potential.

Input Power Cables/ Wiring

Input wiring can be any of:

• A four conductor cable (three phases and ground/protective earth). Shielding is

not required.

• Four insulated conductors routed through conduit.

Size wiring according to local safety regulations, appropriate input voltage and the

drive’s load current. In any case, the conductor must be less than the maximum limit

defined by the terminal size (see "Drive’s Power Connection Terminals" on page

223).

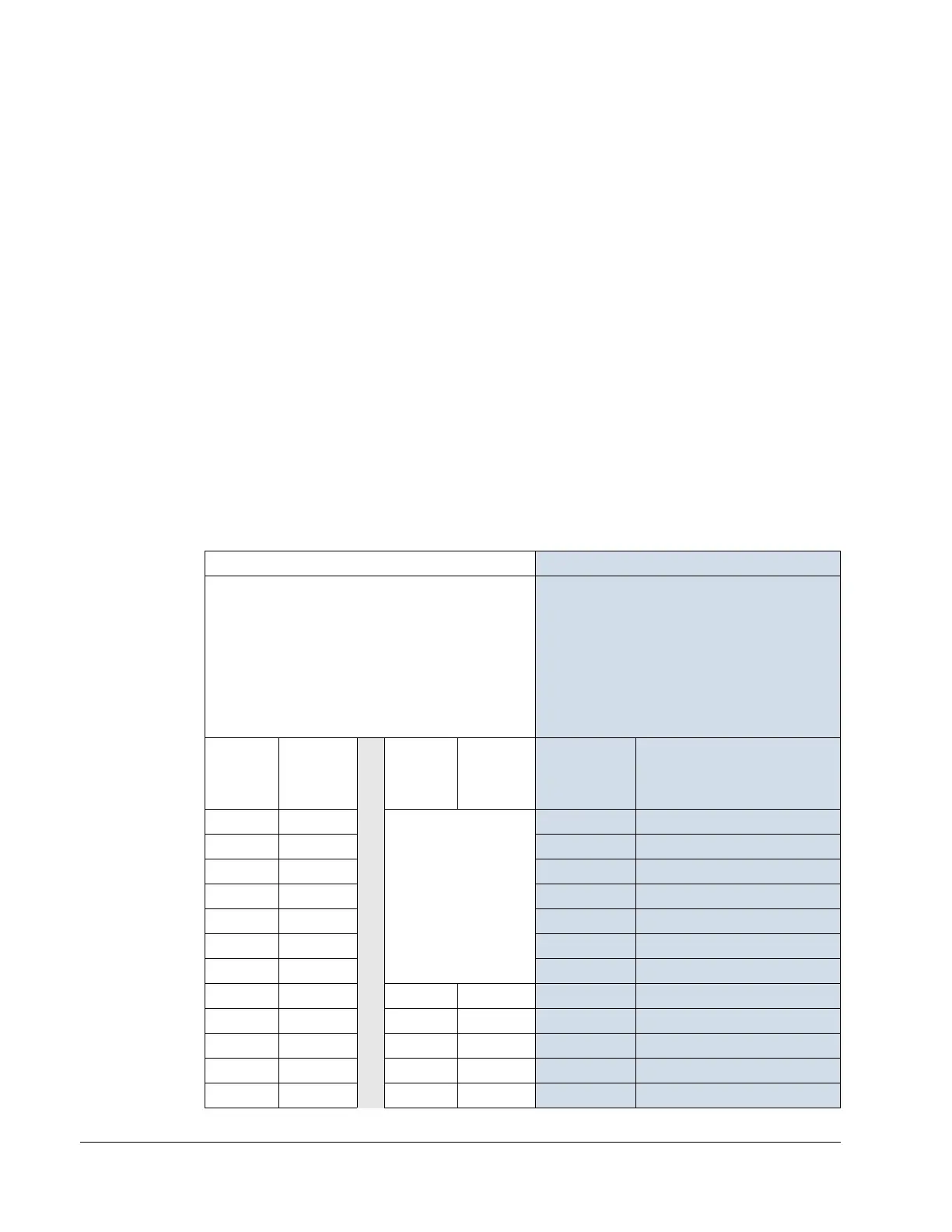

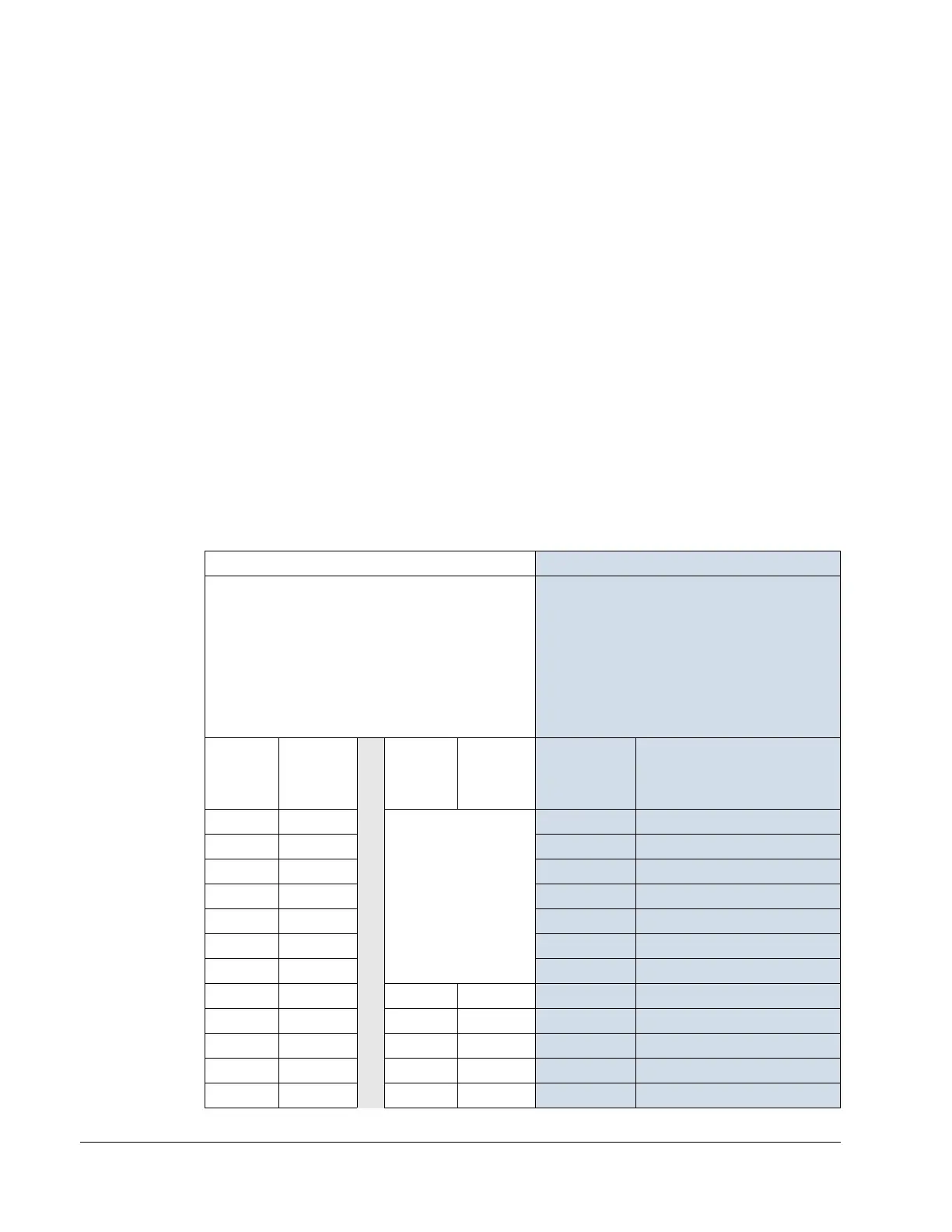

The table below lists copper and aluminum cable types for different load currents.

These recommendations apply only for the conditions listed at the top of the table.

IEC NEC

Based on:

• EN 60204-1 and IEC 60364-5-2/2001

• PVC insulation

• 30 °C (86 °F) ambient temperature

• 70 °C (158 °F) surface temperature

• Cables with concentric copper shield

• Not more than nine cables laid on cable ladder

side by side.

Based on:

• NEC Table 310-16 for copper wires

• 90 °C (194 °F) wire insulation

• 40 °C (104 °F) ambient temperature

• Not more than three current-carrying

conductors in raceway or cable, or earth

(directly buried).

• Copper cables with concentric copper shield

Max

Load

Current

(A)

Cu Cable

(mm

2

)

Max

Load

Current

(A)

Al Cable

(mm

2

)

Max Load

Current

(A)

Cu Wire Size

(AWG/kcmil)

14 3x1.5 Do not use aluminum

cable with frame sizes

R1…R4

22.8 14

20 3x2.5 27.3 12

27 3x4

36.4 10

34 3x6 50.1 8

47 3x10

68.3 6

62 3x16

86.5 4

79 3x25 100 3

98 3x35

91 3x50 118 2

119 3x50

117 3x70 137 1

153 3x70

143 3x95 155 1/0

186 3x95 165 3x120 178 2/0

215 3x120

191 3x150 205 3/0

Loading...

Loading...