280 PROFINET IO – Start-up

7. Define the process data transferred to and from the drive in

parameter groups 52 and 53.

Note: The adapter module automatically sets the

communication profile-specific virtual address for the Status

word in parameter 52.01 and for the Control word in parameter

53.01.

8. Validate the settings made in parameter groups 51, 52 and 53

with parameter 51.27 FBA par refresh.

9. Set the relevant drive control parameters to control the drive

according to the application.

Examples of appropriate values are shown in the tables below.

Parameter setting examples – ACS850 and ACQ810

Speed control using the PROFIdrive communication

profile with PPO Type 4

This example shows how to configure a basic speed control

application that uses the PROFIdrive profile. In addition, some

application-specific data is added to the communication.

The start/stop commands and reference are according to the

PROFIdrive profile, speed control mode. For more information, see

the PROFIdrive state machine on page 312.

The reference value ±16384 (4000h) corresponds to parameter

19.01 Speed scaling in the forward and reverse directions.

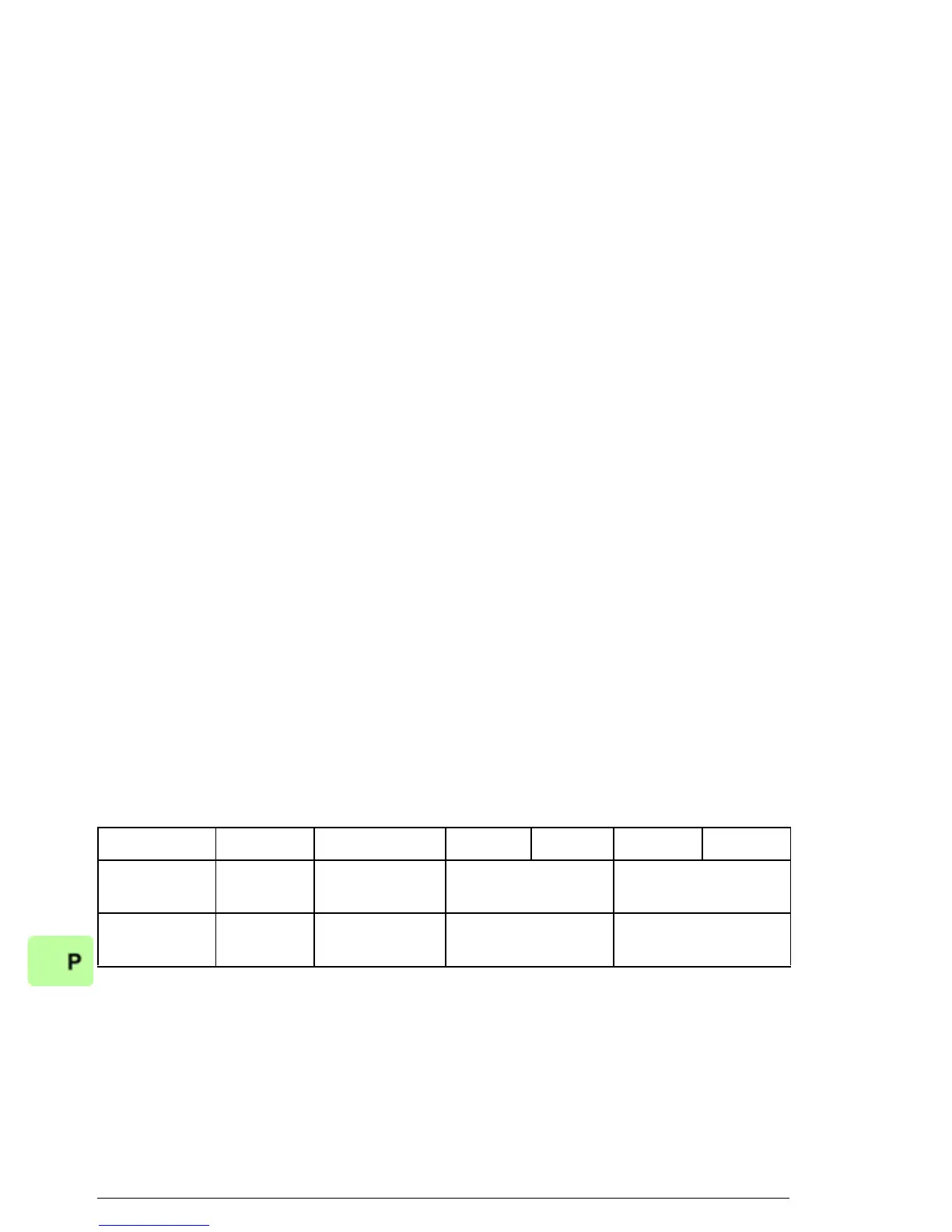

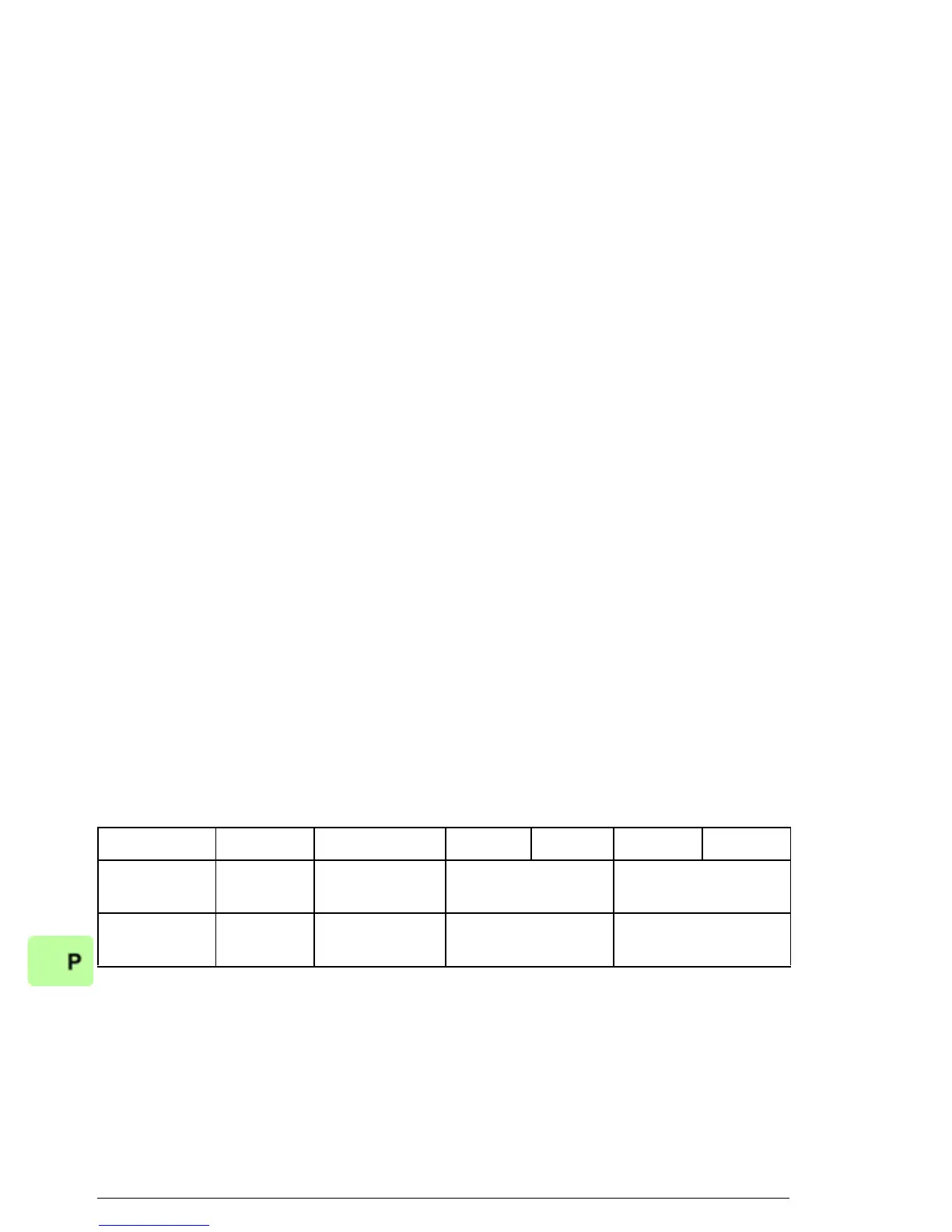

Direction PZD1 PZD2 PZD3 PZD4 PZD5 PZD6

Out Control

word

Speed

reference

Constant speed 1

1)

Constant speed 2

1)

In Status

word

Speed Actual

value

Power

1)

DC bus voltage

1)

1)

Example

Loading...

Loading...