IF THE CHAIN ROLLERS ARE DAMAGED, THE PINS ARE LOOSE AND/OR THE SEAL RINGS

ARE MISSING OR DAMAGED, THE WHOLE CHAIN UNIT (PINION, SPROCKET AND CHAIN)

SHOULD BE REPLACED.

LUBRICATE THE CHAIN ON A REGULAR BASIS, PARTICULARLY IF YOU DETECT DRY OR

RUSTY PARTS.

FLATTENED OR JAMMED CHAIN LINKS SHOULD BE LUBRICATED AND GOOD OPERATING

CONDITIONS RESTORED.

THE GEARING CHAIN HAS SEALING RINGS AMONG THE LINKS THAT KEEP THE GREASE

INSIDE.

ADJUST, LUBRICATE, WASH AND REPLACE THE CHAIN WITH UTMOST CAUTION.

CLEANING AND LUBRICATION

Do not wash the chain with water jets, steam jets, high-pressure water jets and highly flammable sol-

vents.

•

Wash the chain with fuel oil or kerosene. Maintenance operations should be more frequent

if there are signs of quick rust.

Lubricate the chain at the intervals specified on the routine maintenance table and whenever necessary.

•

Wash the chain, allow to dry and lubricate with spray grease for sealed chains.

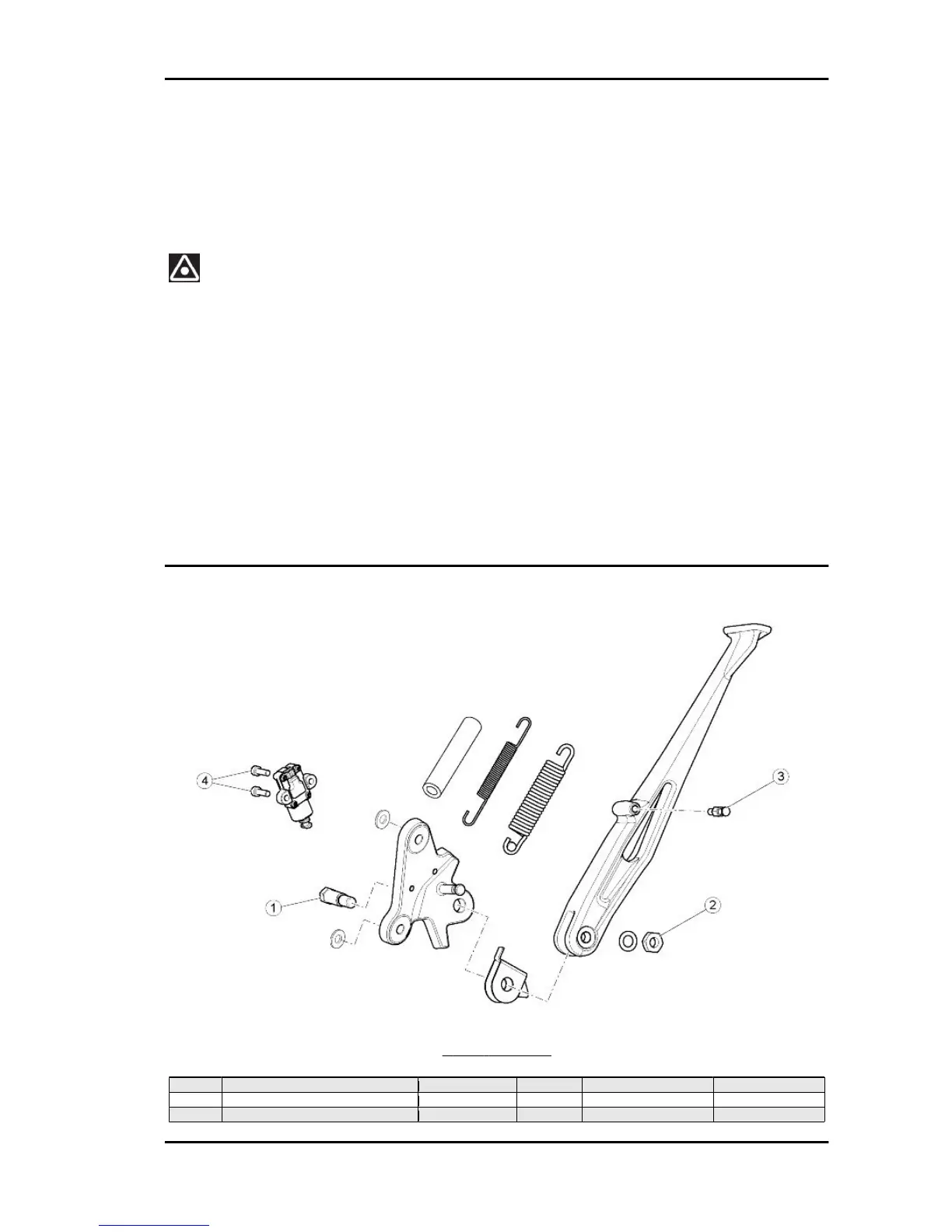

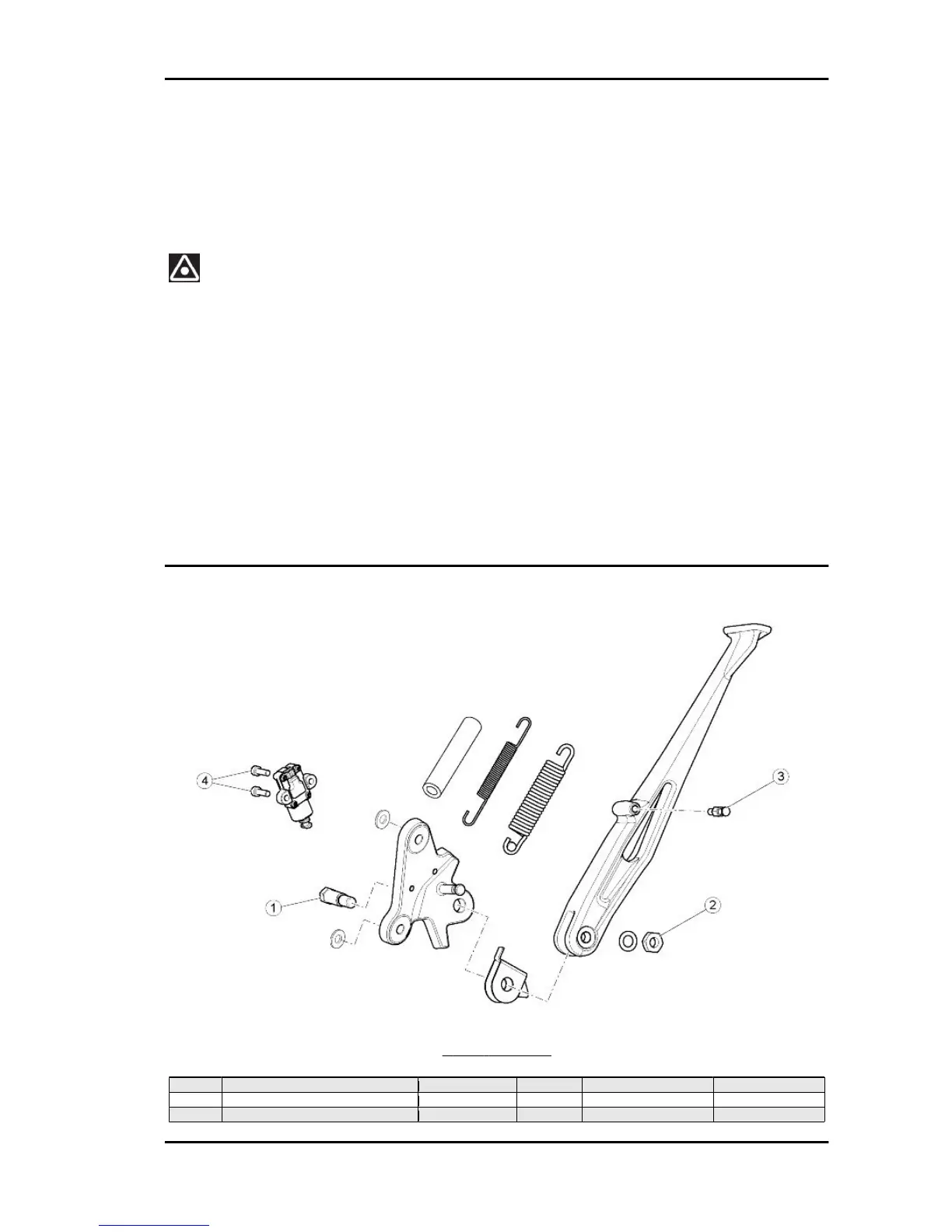

Stand

STAND ASSEMBLY

pos. Description Type Quantity Torque Notes

1 Stand bolt M10x1.25 1 10 Nm (7.37 lbf ft) -

2 Thin nut M10x1.25 1 25 Nm (18.44 lbf ft) Loctite 243

3 Spring fixing pin - 1 7.5 Nm (5.53 lbf ft) -

DORSODURO 1200 ABS - ATC Chassis

CHAS - 335

Loading...

Loading...