330

APPENDIX G — MAINTENANCE SUMMARY AND LOG SHEETS

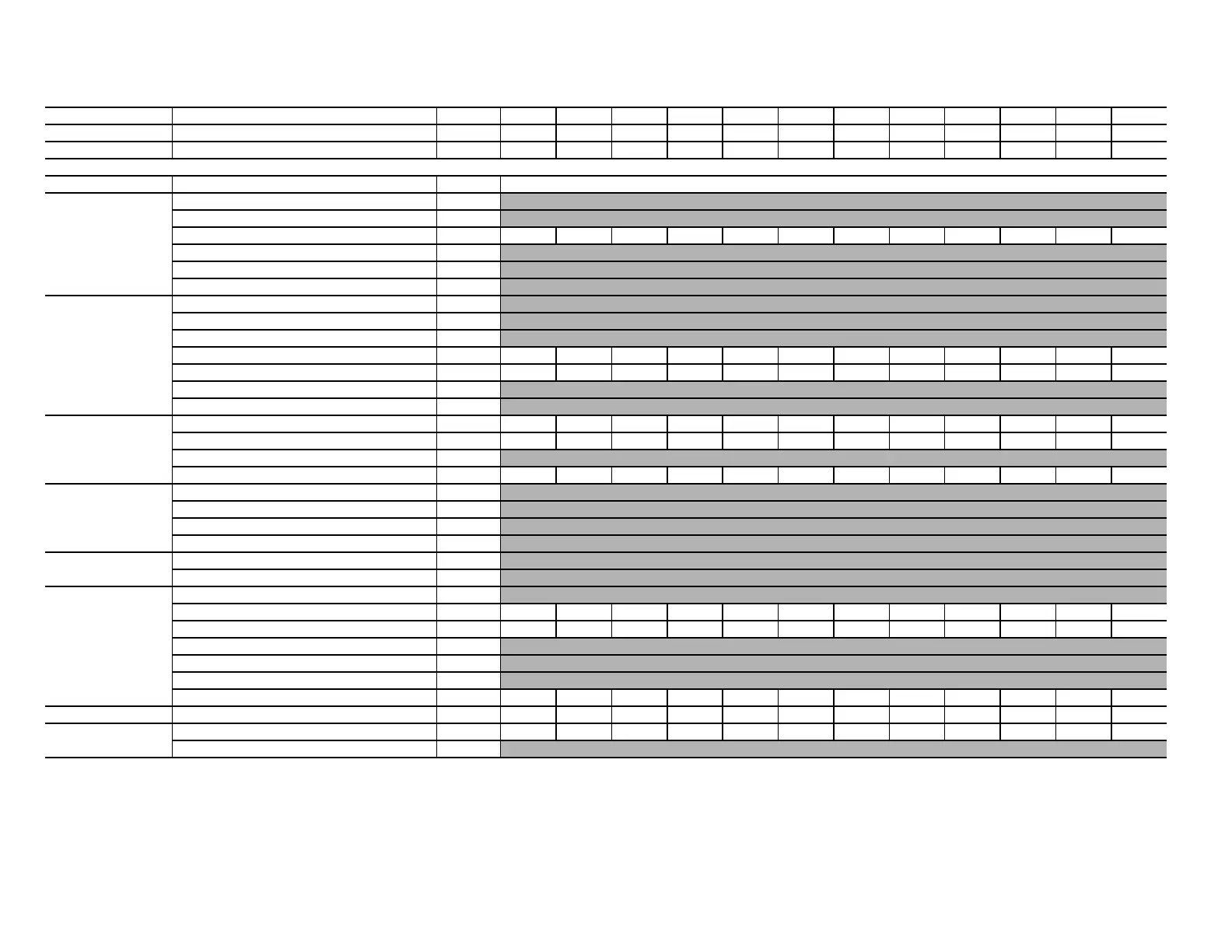

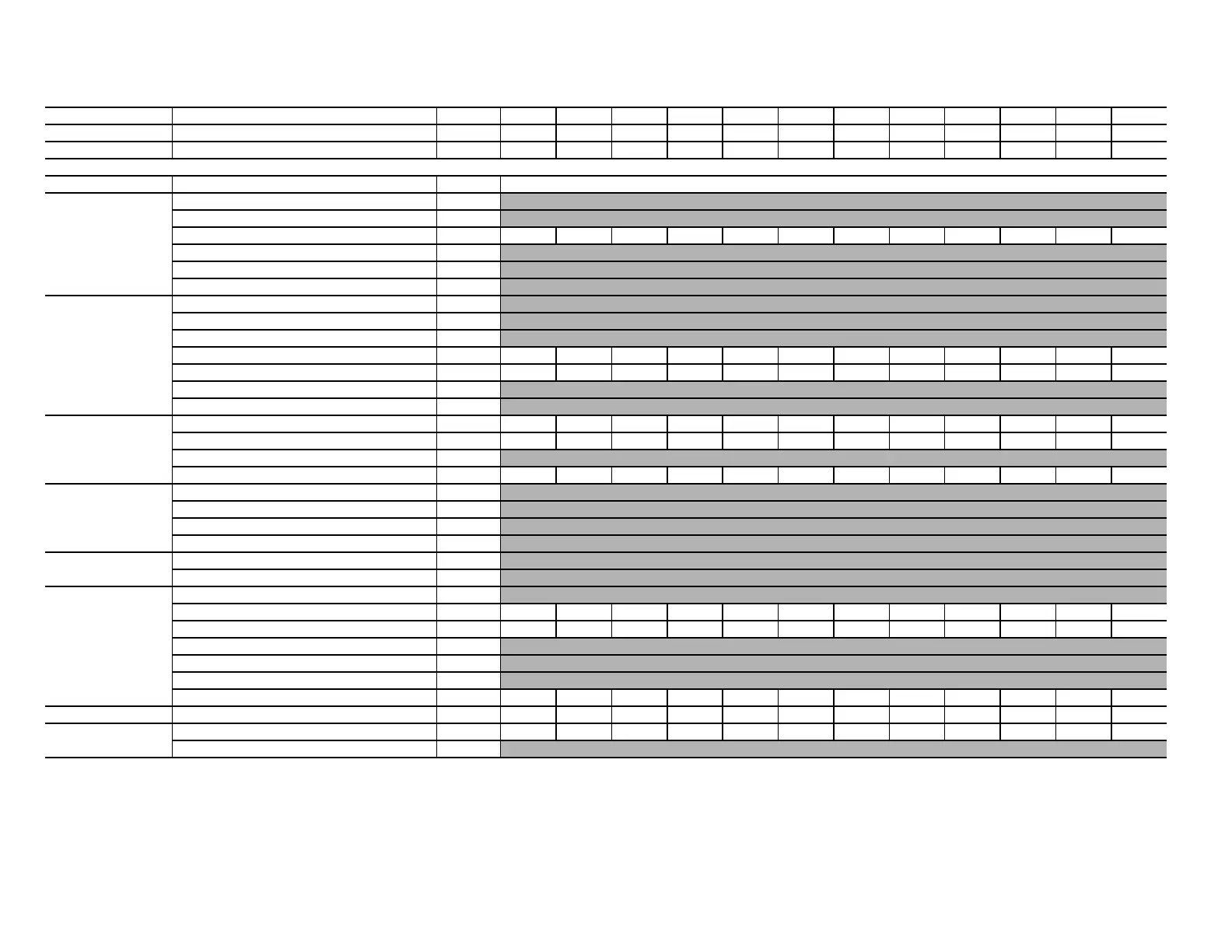

30XV Monthly Maintenance Log

NOTE: Equipment failures caused by lack of adherence to the Maintenance Interval Requirements are not covered under warranty.

Month 123456789101112

Date / / / / / / / / / / / / / / / / / / / / / / / /

Operator

UNIT SECTION ACTION UNIT ENTRY

Compressor

Change Oil Filter (Screw Compressors)

yes/no Year 1 then As Needed

Send Oil Sample Out for Analysis

yes/no Annually

Leak Test

yes/no

Check Oil Separator Heater

Every 3 months

Check Oil Filter Pressure Drop

Every 3 months

Check Glycol Concentration

Annually

Evaporator

Inspect and Clean Evaporator Tubes

yes/no Every 3 - 5 Years

Inspect Evaporator Heater

amps Annually

Inspect Relief Valves

yes/no Annually

Leak Test

yes/no

Record Water Pressure Differential (PSI)

PSI

Check glycol concentration

Annually

Eddy Current Test

yes/no Every 3 - 5 Years

Condenser

Leak Test

yes/no

Inspect and Clean Condenser Coils

yes/no

Check condenser fan operation and condition

Every 3 months

Inspect Relief Valves

yes/no

Controls

General Cleaning and Tightening Connections

yes/no Annually

Check Pressure Transducers for Accuracy

yes/no Annually

Verify Flow Switch Operation

yes/no Every 3 months

Confirm Accuracy of Thermistors

yes/no Annually

Electrical

General Tightening and Cleaning Connections

yes/no Annually

Inspect All Contactors

yes/no Annually

System

Check Refrigerant Charge

yes/no Annually

Verify Operation of EXVs

yes/no

Check moisture indicating sight glass

Check refrigerant joints and valves for leaks

Every 3 months

Check filter drier for pressure drop

Annually

Check chilled water strainers

Annually

Record System Superheat

deg. F

Compressor VFD

Clean or replace drive filters

yes/no

All VFD

Check cooling fan operation

yes/no

Verify heat sinks are clear of debris

yes/no Every 3 months

Loading...

Loading...