49

remains in this mode until the LWT, the compressor load,

or the outdoor temperature changes by a defined amount.

If the change conditions are met the fan control goes back

to the WAITOPT mode followed by the OPTIMZE modes.

• DGT: High Discharge Gas Temperature mode. The VFD

increases the speed of the fan to reduce DGT.

• DP_HIGH, DP_LOW: High Discharge Pressure (DP)

Mode, Low Discharge Pressure Mode: The VFD controls

the speed of the fan to bring SCT (Saturated Condensing

Temperature) into normal operating range.

• OFF: Fans are not running.

• START: Start mode. The frequency of the fans is defined

based on the OAT.

Head Pressure Control (Fixed Speed Fans)

The head pressure is controlled through the Carrier Controller

display by adjusting the number of fans running. The controller

determines the minimum number of fans required to support

unit operation so the unit can run at the most efficient point. At

start up the number of fans on is calculated using OAT. After

60 seconds, an equation is used to determine the number of fan

required based on OAT, EWT, and circuit capacity.

There are additional modes used for fixed speed fans:

DP HIGH

Mode decreases the discharge pressure as fast as possible to

prevent high pressure trips. This mode turns on all fans.

DP HIGH DISCHARGE PRESSURE

Mode avoids high discharge pressure that would cause the com-

pressor to run outside of the compressor envelope. In this mode,

the pressure is controlled to a Discharge Pressure set point.

DGT HIGH

Mode decreases the discharge temperature as fast a possible to

prevent high DGT alarms. This mode turns on all fans.

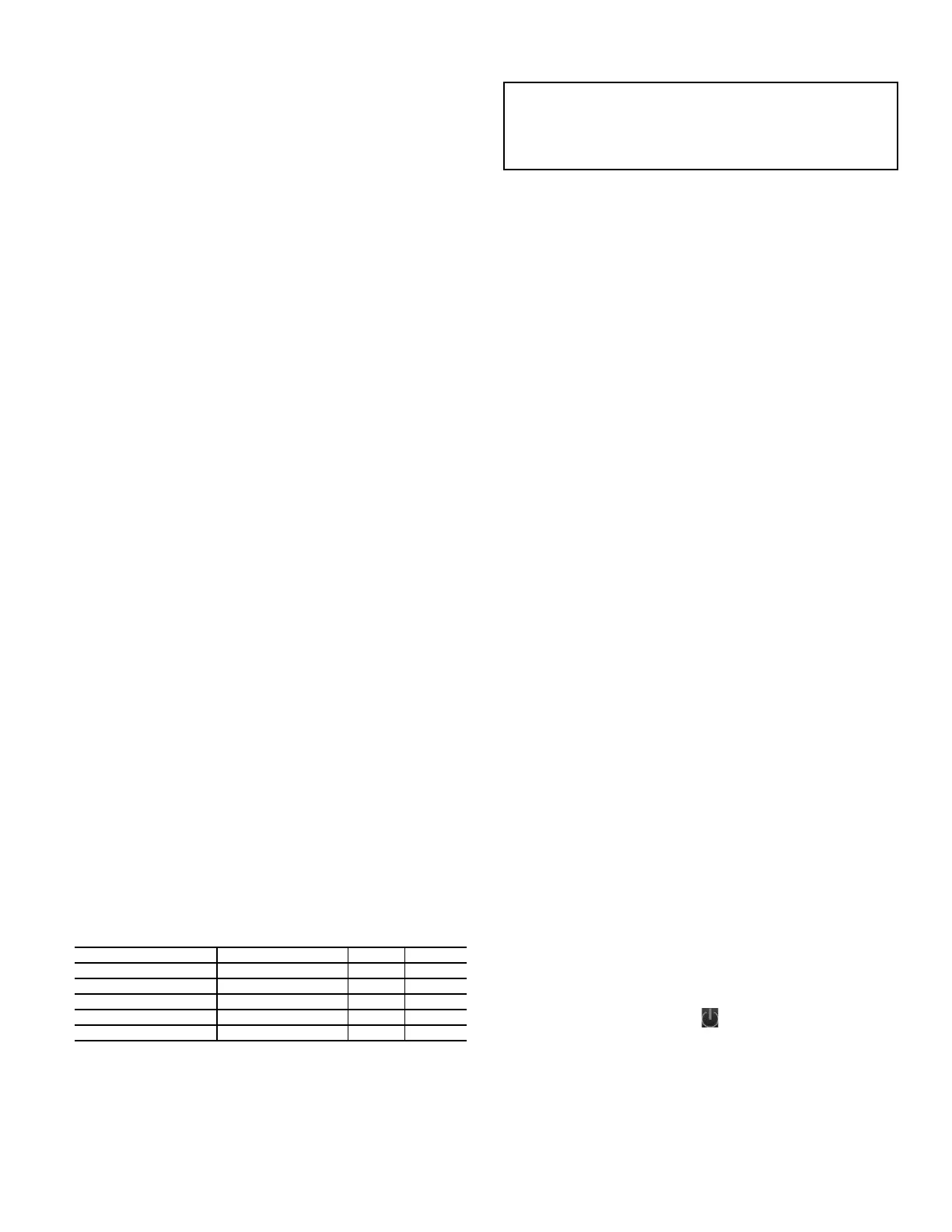

Sound Optimization

This option runs the chiller at a lower sound level by limiting the

compressor and fan speed. The factors in Table 32 control this

option. The factors are set from the factory and should not be

lowered, as this may cause operational issues. The set points for

this option are on a label inside the door of the control panel.

The compressor speed, fMaxOvrA or B, can be set to a lower

max frequency. The max frequency is limited by the max fre-

quency of the base unit. This option is enabled by changing

fMaxEnA or B to “yes”.

The fan speed limitation is enabled by setting fan_fact to any

value other than 1.00. The factor will be applied to the fan curve

calculation for the fan speed in Hz. If the factor is 0.7, the fan

speed will be 70% of the calculated fan speed. If high saturated

condensing temperature occurs, the controls will override this

feature and increase fan speed to keep the chiller running.

Table 32 — Sound Optimization Factor Settings

PRE-START-UP

Do not attempt to start the chiller until the following checks

have been completed.

System Check

1. Check that auxiliary components, such as the chilled fluid

circulating pump, air-handling equipment, or other equip-

ment to which the chiller supplies liquid are operational.

Consult manufacturer’s instructions. If the unit has field-

installed accessories, be sure all are properly installed and

wired correctly. Refer to unit wiring diagrams.

2. Open compressor suction service valves (if equipped).

3. Open discharge line, liquid line, oil line, and economizer (if

equipped) service valves.

4. Fill the chiller fluid circuit with clean water (with recom-

mended inhibitor added) or other non-corrosive fluid to be

cooled. Bleed all air out of high points of system. If outdoor

temperatures are expected to be below 32°F (0°C), sufficient

inhibited propylene glycol or other suitable corrosion inhibit-

ed antifreeze should be added to the chiller water circuit to

prevent possible freeze-up.

The chilled water loop must be cleaned before the unit is

connected. It is recommended that the chiller pumps be

equipped with a start-up filter screen to remove particulates

from the loop. The start-up filter should be replaced after 24

hours of operation

5. Check tightness of all electrical connections.

6. Electrical power source must agree with unit nameplate.

7. Oil separator heaters must be energized for 24 hours prior to

start-up.

START-UP

Actual Start-Up

Actual start-up should be done only under supervision of a

qualified refrigeration technician.

1. Be sure all oil, suction valves, discharge valves (if equipped)

and liquid line service valves are open.

2. Using the Carrier Controller control, set leaving-fluid set

point (Main Menu

Setpoint Table

Cooling Setpoint

1). No cooling range adjustment is necessary.

3. If optional control functions or accessories are being used,

the unit must be properly configured. Refer to Configuration

Options section for details.

4. Start the chilled fluid pump, if unit is not configured for

pump control (Main Menu

Configuration Menu

Pump Configuration

Evaporator Pumps Sequence =

No Pumps (0)).

5. Complete the Start-Up Checklist to verify all components

are operating properly.

6. Touch the Start/Stop button located in the upper right cor-

ner of the Carrier Controller display and then select Local On.

7. Allow unit to operate and confirm that everything is func-

tioning properly. After unit operation stabilizes, check to see

that leaving set-point Control Point (Main Menu

Set-

point Table

Cooling Setpoint 1) agrees with leaving

fluid temperature (Main Menu

Temperatures

Evap

Leaving Fluid).

FACTOR COMPRESSOR SPEED RANGE DEFAULT

Enable Max Frequency A fMaxEnA no/yes 0 (no)

Enable Max Frequency B fMaxEnB no/yes 0 (no)

Max Frequency Override A fMaxOvrA 30 to 105 75

Max Frequency Override B fMaxOvrB 30 to 105 75

Fan Freq Fctor (0.7-1.1) fan_fact 0.7 to 1.1 1.00

Complete the Start-Up Checklist for 30XV Liquid Chillers

at the end of this publication. The checklist assures proper

start-up of a unit, and provides a record of unit condition,

application requirements, system information, and opera-

tion at initial start-up.

Loading...

Loading...