67

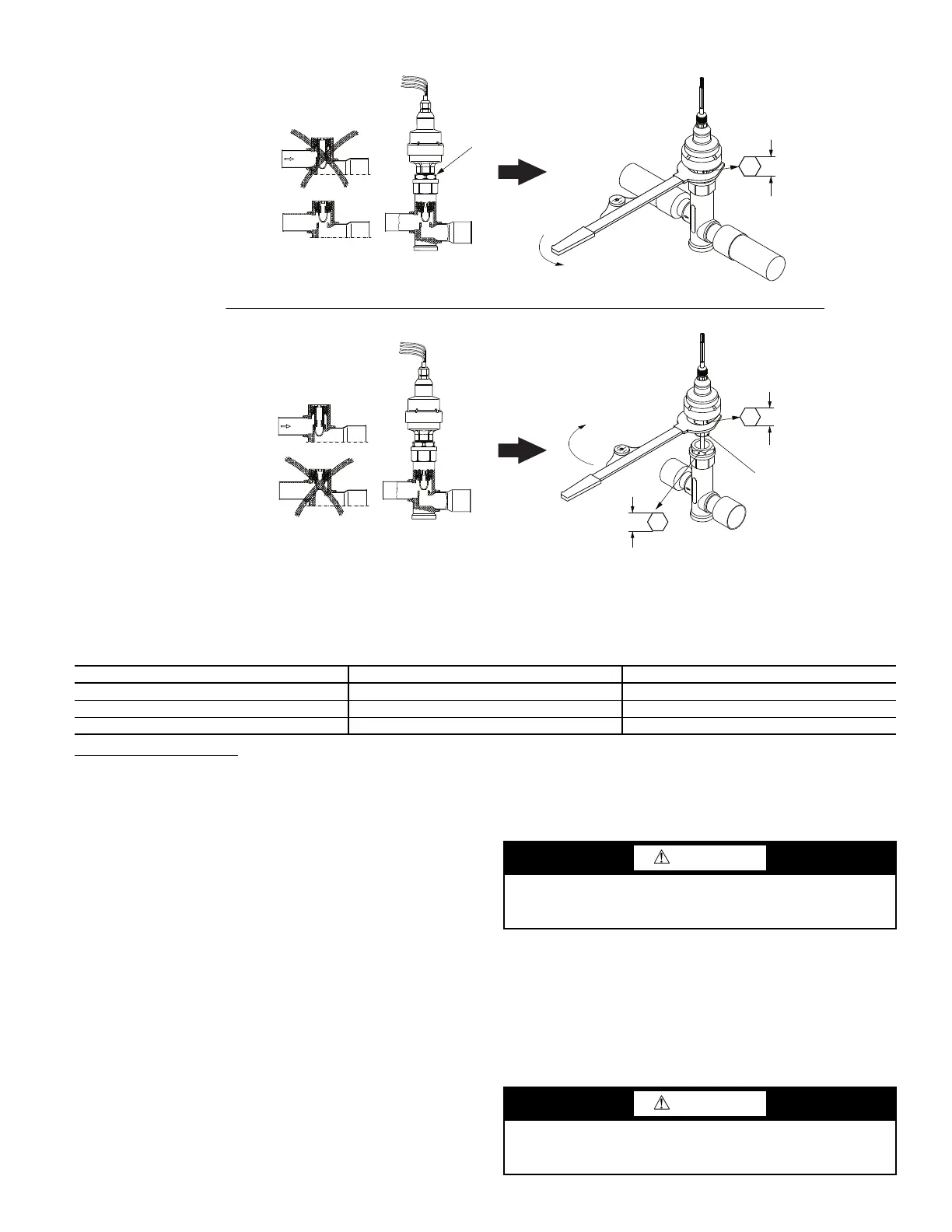

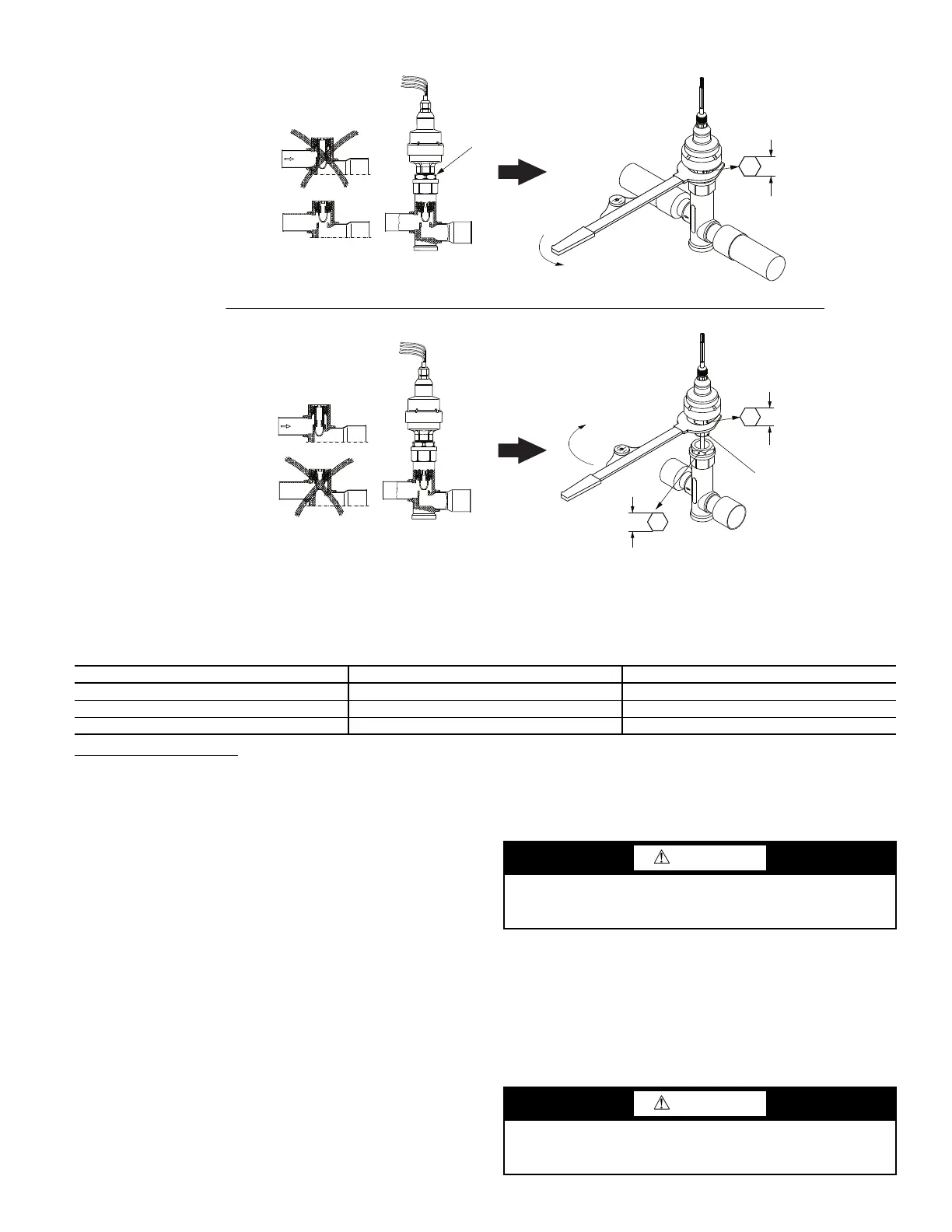

Fig. 61 — Disassembly and Assembly of EXV Motor

Table 41 — Color Indicators When Moisture Is Present in Refrigerant

Liquid Line Service Valve

This valve is located immediately ahead of filter drier, and has a

1

/

4

-in. access connection for field charging. In combination with

compressor discharge service valve, each circuit can be pumped

down into the high side for servicing with plate fin coils. Micro-

channel Heat Exchanger (MCHX) coils have much smaller vol-

ume and cannot accommodate the entire circuit charge.

Compressor Assembly

The 30XV units utilize Greenspeed Intelligence for efficient

operation. The compressor is controlled by a VFD. See Fig. 62

for a view of a typical 06Z compressor. For optimal efficiency

the compressor uses a VI valve to change the inlet area of the

lobes at different loading points. The valve is opened or closed

by a solenoid on the compressor. The control logic looks at cal-

culated parameters to determine the switch point of the valve.

VI VALVE TROUBLESHOOTING

Use the quick test table (Main Menu

Quick Test Table

Circuit X VI) to enable the VI valve output. Enable the valve

output and verify the coil solenoid is energized.

SUCTION VICTAULIC COUPLING INSTALLATION

1. The outside surface of the pipe, between the groove and

the pipe end, must be smooth and free from indentations,

projections (including weld seams), and roll marks to en-

sure a leak-tight seal. All oil, grease, loose paint, and dirt

must be removed. The Victaulic gasket used for refriger-

ant system piping will have a yellow mark on one side of

the gasket lips.

2. Apply a thin coat of Victaulic lubricant or silicone lubricant

to the gasket sealing lips and exterior.

3.

4. Position the gasket over the pipe end. Make sure the gasket

does not overhang the pipe end.

5. Align and bring the two pipe ends together. Slide the gasket

into position and center it between the grooves in each pipe

end. Make sure no portion of the gasket extends into the

groove in either pipe end.

6. Install the housings over the gasket. Make sure the housings’

keys engage the grooves completely on both pipe ends.

COLOR INDICATOR R-134a, 75°F (24°C) (ppm) R-134a, 125°F (52°C) (ppm)

Green — Dry < 30 < 45

Yellow-green — Caution 30-100 45-170

Yellow — Wet >100 >170

CLOSED

OPEN

CLOSED

OPEN

GASKET

OPEN VALVE IN QUICK TEST SUB-MODE BEFORE DISASSEMBLING

EF05BD271 NV 32.5mm

EF05BD331 NV 36mm

50Nm (36 ft-lb)+ 30°

27mm / 1

1

/

16

''

27mm / 1

1

/

16

''

ADAPTER

NOTES:

1. Push down on valve piston to close valve before assembling.

2. After valve is assembled close valve in Quick Test sub-mode or cycle power before opening service valve.

a30-4072

DISASSEMBLY

ASSEMBLY

CAUTION

Always use a compatible lubricant to prevent the gasket

from pinching or tearing during installation. Failure to fol-

low this instruction could result in joint leakage.

CAUTION

Make sure the gasket does not become rolled or pinched while

installing the housings. Failure to follow this instruction could

cause damage to the gasket, resulting in joint leakage.

Loading...

Loading...