45

EXTERNALLY POWERED (4 TO 20 MA) DEMAND LIMIT

The energy management module is required for 4 to 20 mA

demand limit control. An externally powered 4 to 20 mA sig-

nal must be connected to TB6-1 and TB6-2. This signal is

read by a transducer type (0 to 5 vdc) on the EMM board via

a field-installed 0.5 W 250-ohm resistor.

To configure demand limit for 4 to 20 mA control based on unit

capacity, one parameter must be configured. The parameter is

Demand Limit Type Select. The value of the capacity limit will

vary linearly for 0% to 100% based on the input signal where 4

mA is 100% and 20 mA is 0% of total unit capacity.

To configure this option with the Carrier Controller display:

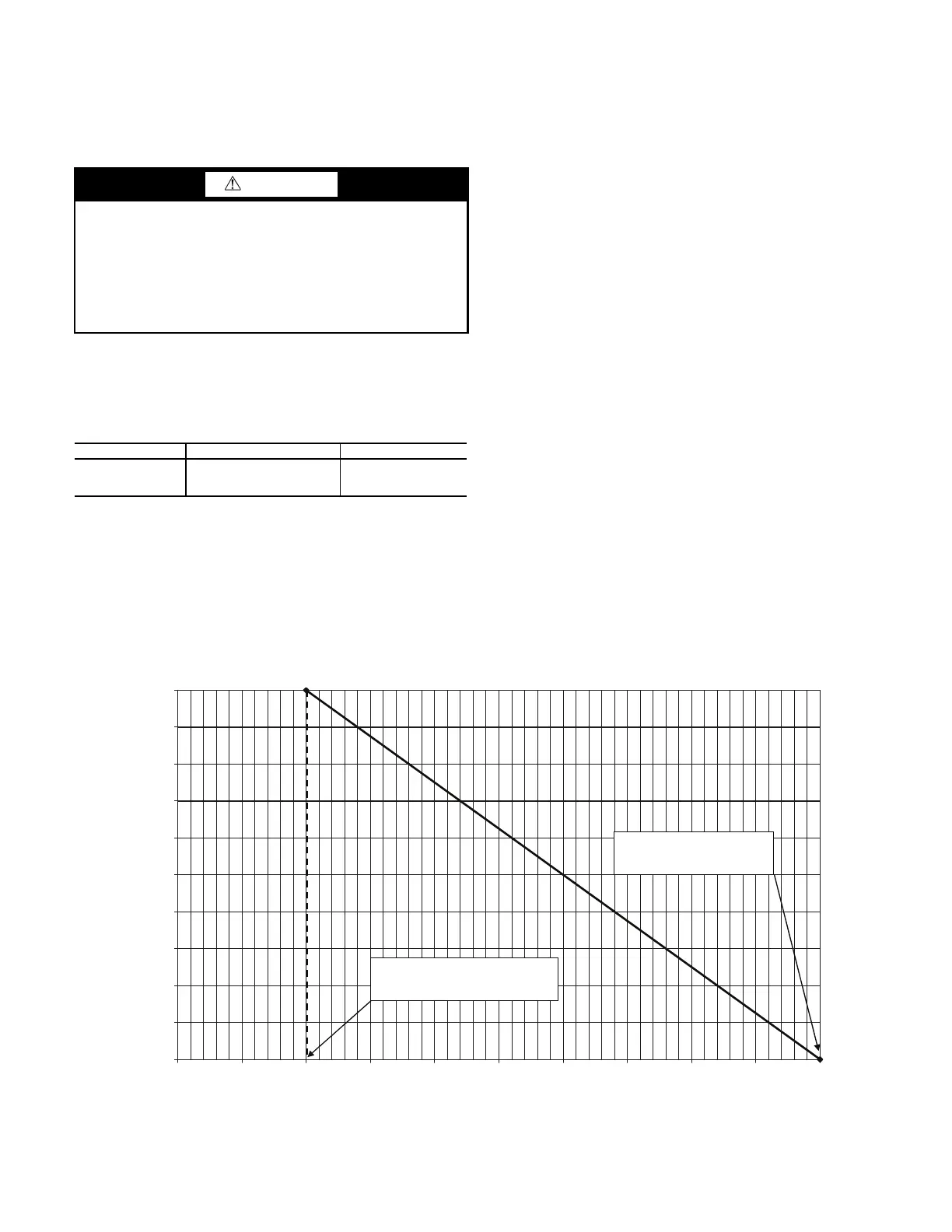

In the example in Fig. 43, a 4 mA signal is Demand Limit

100% and a 20 mA Demand Limit signal is 0%. The 4 to 20

mA signal is connected to TB6-1 and TB6-2. The demand limit

is a linear interpolation between the two values entered. If the

machine receives a 12 mA signal, the machine controls will

limit the capacity to 50%.

CCN LOADSHED CONTROLLED DEMAND LIMIT

To configure Demand Limit for CCN Loadshed control, the unit

Operating Type Control must be in CCN control. With the Carrier

Controller display, the machine must be started in Network Mode.

Network control can be executed from the GENUNIT table.

The unit must be controlled by a Chillervisor module. The

Chillervisor module can force the demand limit variable and

directly control the capacity of the machine. Additionally, the

unit’s set point will be artificially lowered to force the chiller to

load to the demand limit value.

Machine Start Delay

An option to delay the start of the machine is available. This

parameter is useful in keeping multiple machines from starting

at the same time in case of a power failure. The parameter has a

factory default of 1 minute. This parameter also has a role in

the timing for a chilled water flow switch alarm. To configure

this option with the Carrier Controller display, select Main

Menu

Configuration Menu

General Configuration and

select Unit Off to On Delay.

Fast Loading

The Fast Capacity Recovery function allows for an accelerated

unit start-up. This is especially useful following brief power out-

ages at data centers where rapid restart can keep data center op-

erating. This should not be used on normal comfort cooling ap-

plications. To activate the Fast Capacity Recovery, go to Main

Menu

Configuration Menu

Service Parameters and set

Fast Capacity Recovery. The available options are as follows:

• Disabled (normal loading sequence): Follows the set delays

for unit and circuit start up

• Quick start Load - (Quick Start Loading): With Flow es-

tablished, ignores Capacity Control Override #53 (ON-

OFF-ON Delay)

• Fast Capacity Recov (Fast Capacity Recovery): With Flow

established, ignores Capacity Control Override #53 (ON-

OFF-ON Delay), and allows both compressors to start at

the same time (with a 10-second delay between starts)

NOTE: Unit cannot operate with Ramp Loading enabled if

Fast Capacity Recovery is set to Quick start Load or Fast Ca-

pacity Recov.

Fig. 43 — Example: 4 to 20 mA Demand Limit

CAUTION

Care should be taken when interfacing with other control sys-

tems due to possible power supply differences such as a full

wave bridge versus a half wave rectification. Connection of

control devices with different power supplies may result in

permanent damage. Carrier Controller controls incorporate

power supplies with half wave rectification. A signal isola-

tion device should be utilized if the signal generator incorpo-

rates a full wave bridge rectifier.

DISPLAY NAME PATH VALUE

Demand Limit

Type Select

Main Menu

Configuration Menu

General Configuration

Default = 0 (None)

4 to 20mA Control = 2

0

10

20

30

40

50

60

70

80

90

100

12 14 16 18

20

mA Demand Limit Signal

% Demand Limit

0

2

4 6

8 10

mA for Demand Limit = 100%

(lim_mx)

mA for Demand Limit = 0%

(lim_ze)

a30-5883

Loading...

Loading...