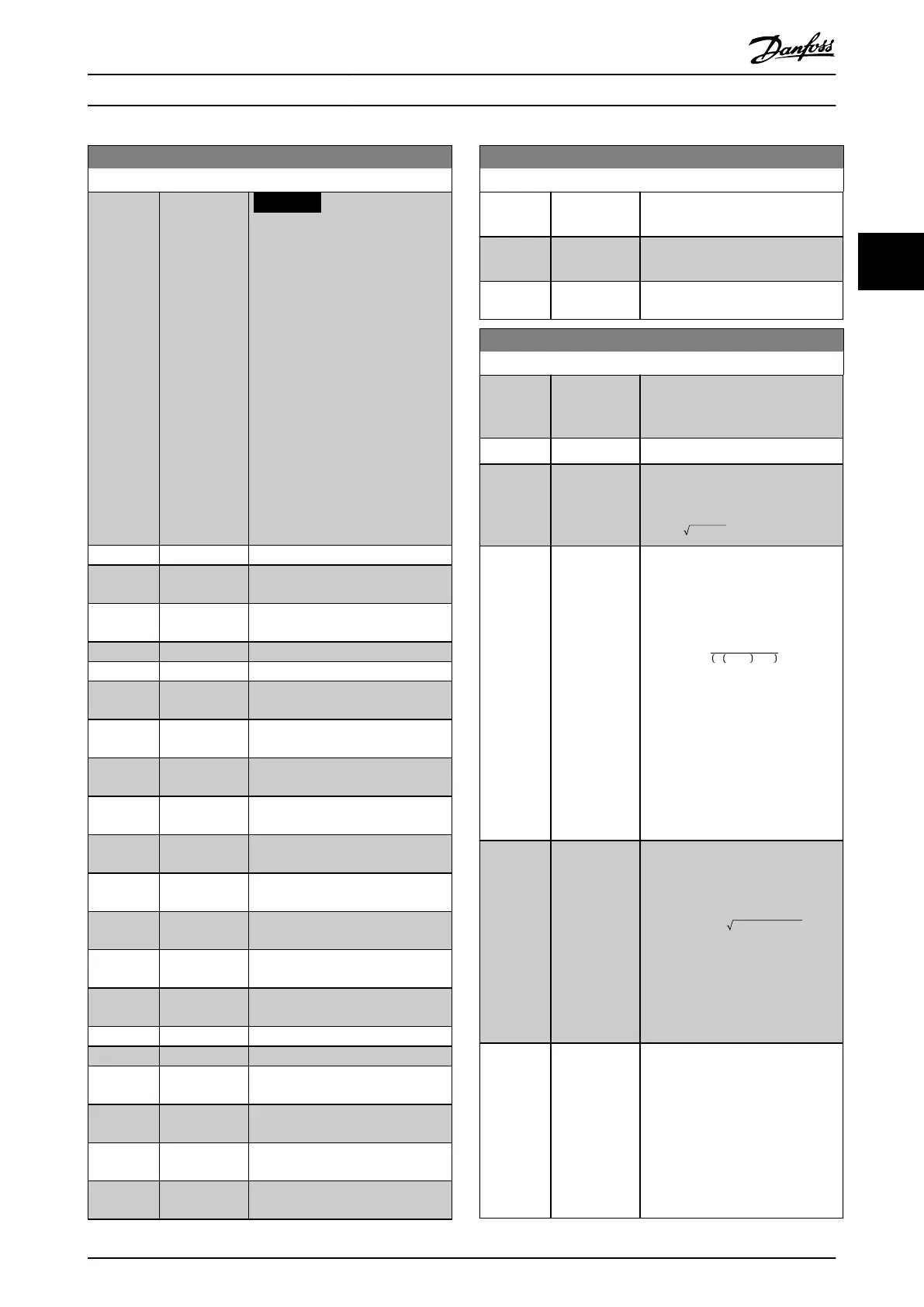

20-00 Feedback 1 Source

Option: Function:

NOTICE

If feedback is not used, set its

source to [0] No Function.

Parameter 20-20 Feedback

Function determines how the

PID controller uses the 3

possible feedbacks.

Up to 3 dierent feedback signals

can be used to provide the

feedback signal for the frequency

converter’s PID controller.

This parameter denes which input

is used as the source of the rst

feedback signal.

Analog input X30/11 and analog

input X30/12 refer to inputs on

VLT

®

General Purpose I/O MCB 101.

[0] No function

[1] Analog Input

53

[2] * Analog Input

54

[3] Pulse input 29

[4] Pulse input 33

[7] Analog Input

X30/11

[8] Analog Input

X30/12

[9] Analog Input

X42/1

[10] Analog Input

X42/3

[11] Analog Input

X42/5

[15] Analog Input

X48/2

[16] Analog Input

X49/1

[17] Analog Input

X49/3

[18] Analog Input

X49/5

[19] Pressure 3

[20] Pressure 4

[99] Normal

Feedback

[100] Bus Feedback

1

[101] Bus Feedback

2

[102] Bus feedback

3

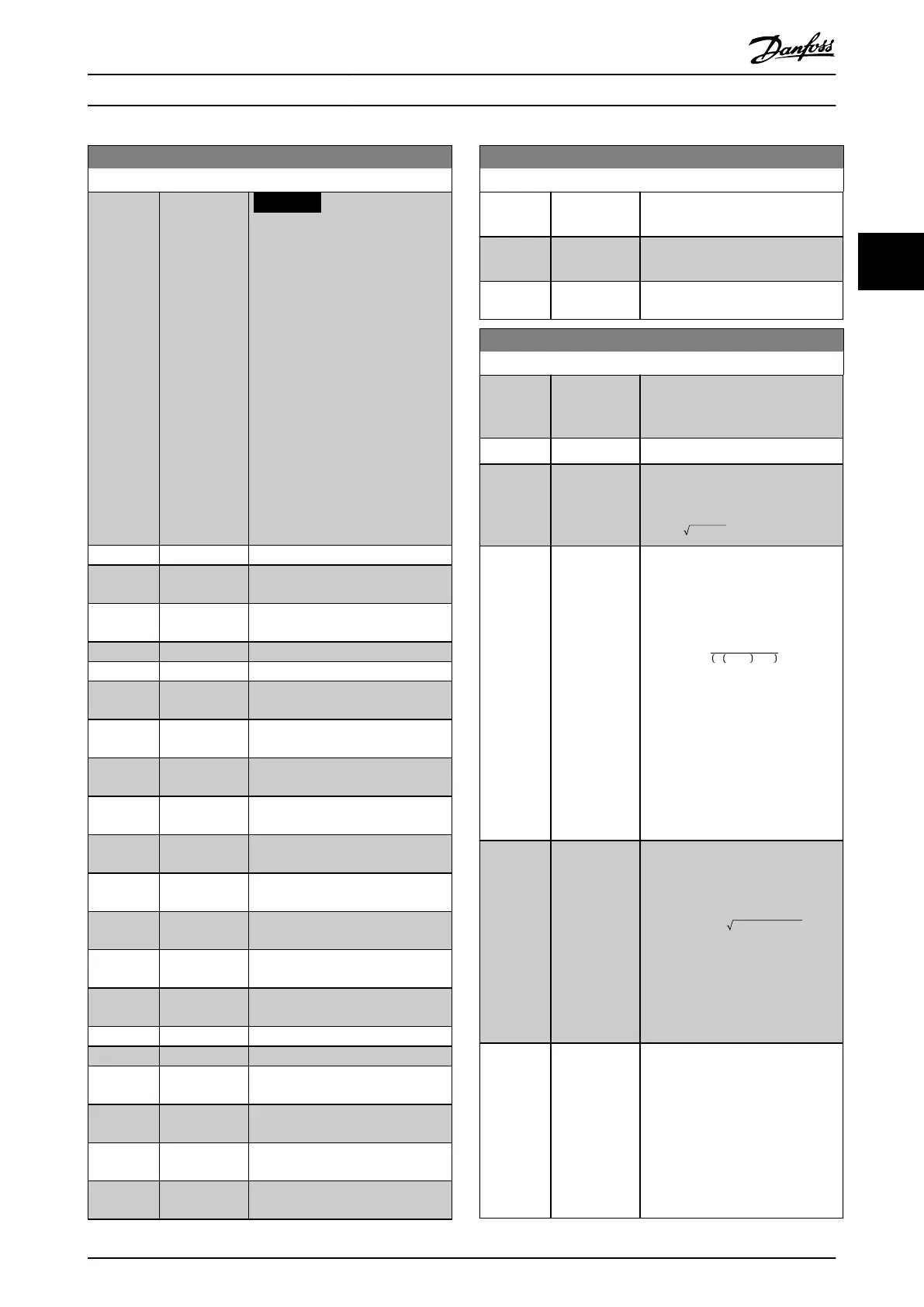

20-01 Feedback 1 Conversion

Option: Function:

This parameter allows a conversion

function to be applied to feedback

1.

[0] * Linear No eect on the feedback.

[1] Square root Commonly used when a pressure

sensor is used to provide ow

feedback

(( flow ∝ pressure)).

[2] Pressure to

temperature

Used in compressor applications to

provide temperature feedback using

a pressure sensor. The temperature

of the refrigerant is calculated using

the following formula:

Temperature =

A2

ln Pe + 1 − A1

− A3,

where A1, A2, and A3 are

refrigerant-specic constants. Select

the refrigerant in

parameter 20-30 Refrigerant.

Parameter 20-21 Setpoint 1 through

parameter 20-23 Setpoint 3 allow the

values of A1, A2, and A3 to be

entered for a refrigerant that is not

listed in parameter 20-30 Refrigerant.

[3] Pressure to

ow

Used in applications for controlling

the air ow in a duct. A dynamic

pressure measurement (pitot tube)

represents the feedback signal.

Flow = DuctArea × DynamicPressure

× AirDensityFactor

See also parameter 20-34 Duct 1

Area [m2] through

parameter 20-38 Air Density Factor

[%] for setting of duct area and air

density.

[4] Velocity to

ow

Used in applications for controlling

the air ow in a duct. An air

velocity measurement represents

the feedback signal.

Flow = DuctArea × AirVelocity

See also parameter 20-34 Duct 1

Area [m2] through

parameter 20-37 Duct 2 Area [in2]

for setting of duct area.

Loading...

Loading...