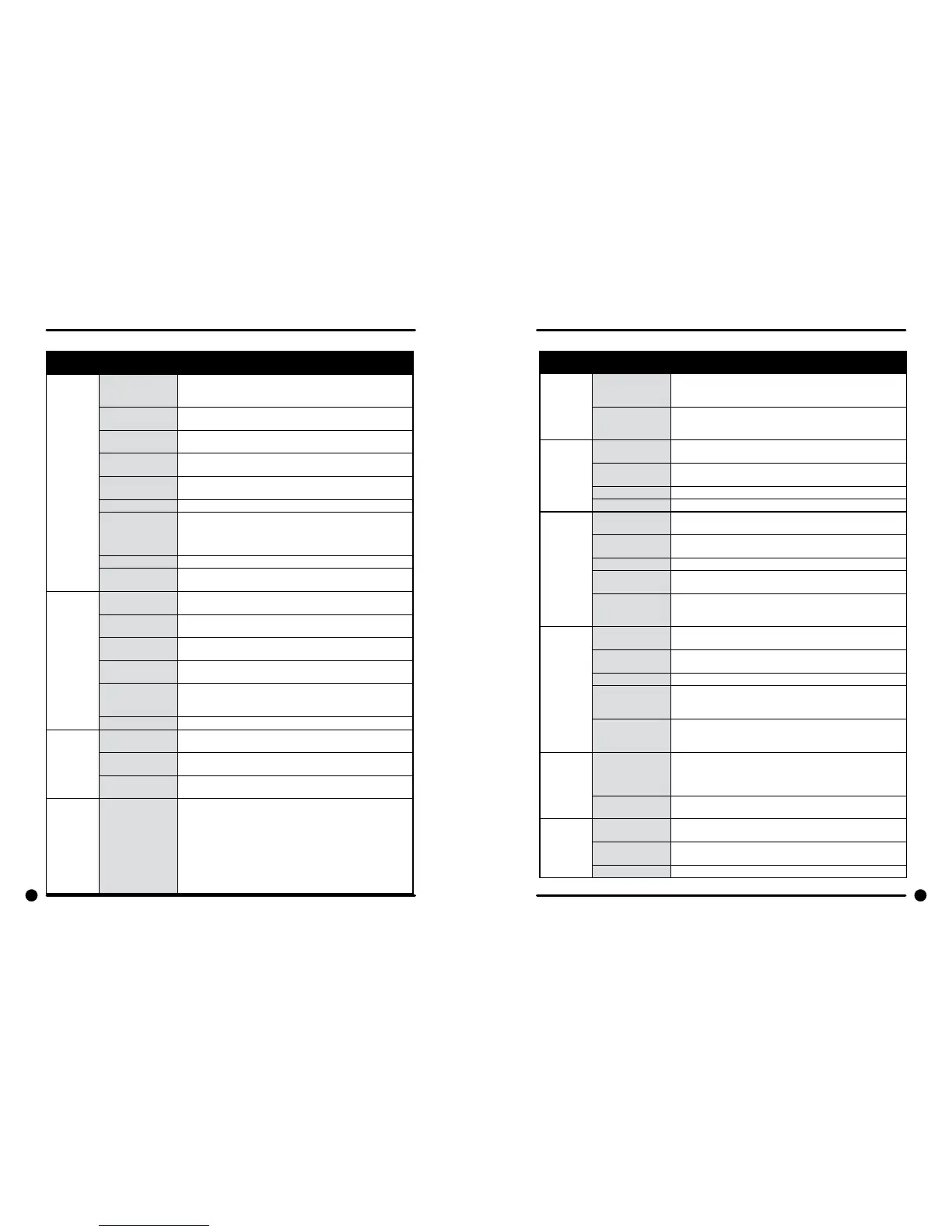

Symptom Probable Cause Suggested Remedy

Machine

does not

start

Power Supply Check these areas: Circuit breakers, Voltage, Power leads,

Power connections. Is front display LED showing a dollar

amount.

Door Switch Check for continuity through door switch when door is

closed. If no continuity, adjust or replace door switch.

Control Breaker or

Fuse

Check 1.5 amp (T-950 and T-1200 use 2.5amp) breaker or

fuse for continuity. If no continuity, replace breaker or fuse.

Control Trans-

former

Check voltage output from control transformer for 120VAC.

If voltage is incorrect, replace transformer.

Coin Acceptor Check coin acceptor to make surethere is no blockage or

damage. clean or replace acceptor.

Check PCB board Check all wire connections for sure contacts.

Check wiring be-

tween PCB

Check data cable. This is the cable with the phone type

connectors on the main PCB control and the VFD. With the

power removed unplug and check for damage, replug and

retry washer.

Check Relay PCB Check all wire connections for sure contact.

Check Door Motor Check that 120 v power is at Motor after start button is

pushed.

Machine will

not accept

and count

coins

Coin Acceptor Check coin acceptor switch for any type of blockage or dam-

age. Clean, adjust or replace the acceptor.

Power Supply Check these areas: Circuit breakers, Voltage,Power leads,

Power connection.

Door Closed Safety

Switch

Check door closed switch at door hinge for proper operation.

Door Handle

Closed Switch

Check single door closed switch at left side of door handle

to close when handle is vertical.

Control Breaker or

fuse

Check breaker or fuse for continuity. If no continuity, re-

place breaker or fuse. The T-300 through T-950 use the 1.5

amp fuse. The T-1200 and t-1450 uses A 2.5 amp fuse.

Main PCB Replace

Door does

not lock

Check display for

fault code

Does Door Lock Error show on the front of display. If yes fol-

low tests described in fault code section.

Door locking Motor Check to insure that Motor is receiving 120VAC from main

relay PCB. If it is, replace solenoid.

Door Switch Check for continuity through door latch switch when door

closed. If no continuity, adjust or replace door switch.

Door will

not open

Thermoactuator Check to see if thermoactuator(s) and/or its mechanism is

stuck or binding and not allowing the door lock solenoid to

open. Check to be sure that the locking thermoactuator is

not receiving 120VAC during the last 1 1/2 minutes of the

cycle. Also check to see that the unlocking thermoactuator

is receiving 120VAC during the last minute of the cycle. If

the thermoactuators do not receive voltage at the correct

times, change the timer. If the timing and voltage are cor-

rect, replace the thermoactuator.

Common Troubleshooting Solutions

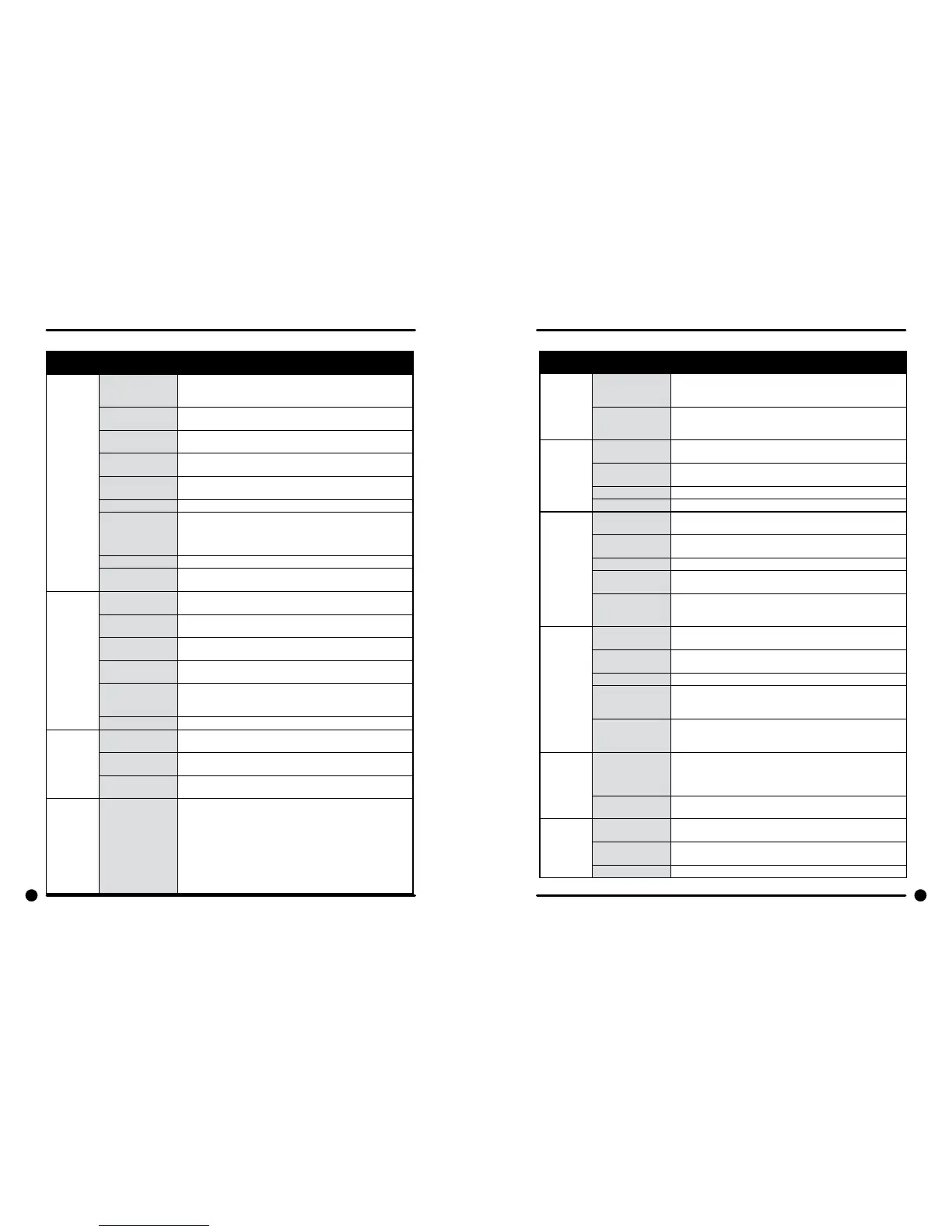

Symptom Probable Cause Suggested Remedy

Door will

not open

Door Rod Check to see that door rod from solenoid to lock ass’y is

long enough to allow lock ass’y to disengage. If not, adjust

rod.

Gear Motor Check the door lock motor. Make sure the motor is not stuck

or in a bind. If motor does not move freely, replace locking

motor.

No hot

water in

detergent

dispenser

Water Valve Coil Check coil continuity at terminals and replace if no continu-

ity. 120 V power only on for 20 second in wash bath.

Water Inlet Check water inlet screens for blockage and clean screens if

necessary.

Water Check to insure that water is turned on and operating.

P-20 Wire Harness Check black & white harness.

Hot water

does not

enter tub in

wash

Water Valve Coil Check coil continuity at terminals and replace if no continu-

ity. Check for 120 V power from main relay PCB

Water Inlet Check water inlet screens for blockage and clean if neces-

sary screens

Water Check to insure that water is turned on and operating.

Blk or Wht wire at

main controller

Check black or white wires at Molex plug on PCB at main

controller and at relay PCB.

Pressure Switch Check pressure switch continuity between terminals . If no

continuity, check pressure switch hose for obstruction. If

hose okay, change pressure switch.

No cold

water to tub

in wash

Water Valve Coil Check coil continuity at terminals and replace if no continu-

ity.

Water Inlet

Screens

Check water inlet screens for blockage and clean if neces-

sar y.

Water Check to insure that water is turned on and operating.

Blk or whit wire

at controller and

main relay PCB

Check black or white wires at Molex plug on PCB at main

controller and at relay PCB.

Pressure Switch Check pressure switch continuity between terminal contacts.

If no continuity, check pressure switch hose for obstruction.

If hose okay, change pressure switch.

Water

comes in

but level

does not

rise

Drain Valve (open) Check these areas • Drain valve blockage • Drain valve mo-

tor and gear train. If power but drain valve does not close,

replace valve. • Power to the drain valve. If no power to

drain valve, check (brn/yel) circuit for power.

Blk or whit wire at

controller

Check black and white wires at molex plug on main PCB

controller and at main relay PCB

Water does

not ush

softener

compart-

ment.

Water Valve Coil Check coil continuity at terminals and replace if no continu-

ity.

Water Inlet

Screens

Check water inlet screens for blockage and clean if neces-

sar y.

Water Check to insure that water is turned on and operating.

Common Troubleshooting Solutions

58 59

Part # 8533-080-001 12/15 Part # 8533-080-001 12/15

Loading...

Loading...