HEALTH & SAFETY

1-10 EPT031055 Issue 2 September 2017

Laser Marking Process

Potential fire risks could result from examples as listed below. This list is not

considered to be complete. Local conditions must be considered as well.

• Printing on not specified material (e.g. easily inflammable or explosive

materials).

• Invalid parameter settings (e.g. very low mark speed).

• Invalid parameter settings due to corrupted print data.

• Printing constantly on the same product (e.g. no product movement

caused by various reasons).

• Inflammable gases or materials inside the working area.

In printing mode the laser beam is controlled by software which must be

considered as part of the risk assessment.

Note: Install a fire detector near the laser to monitor the marking process.

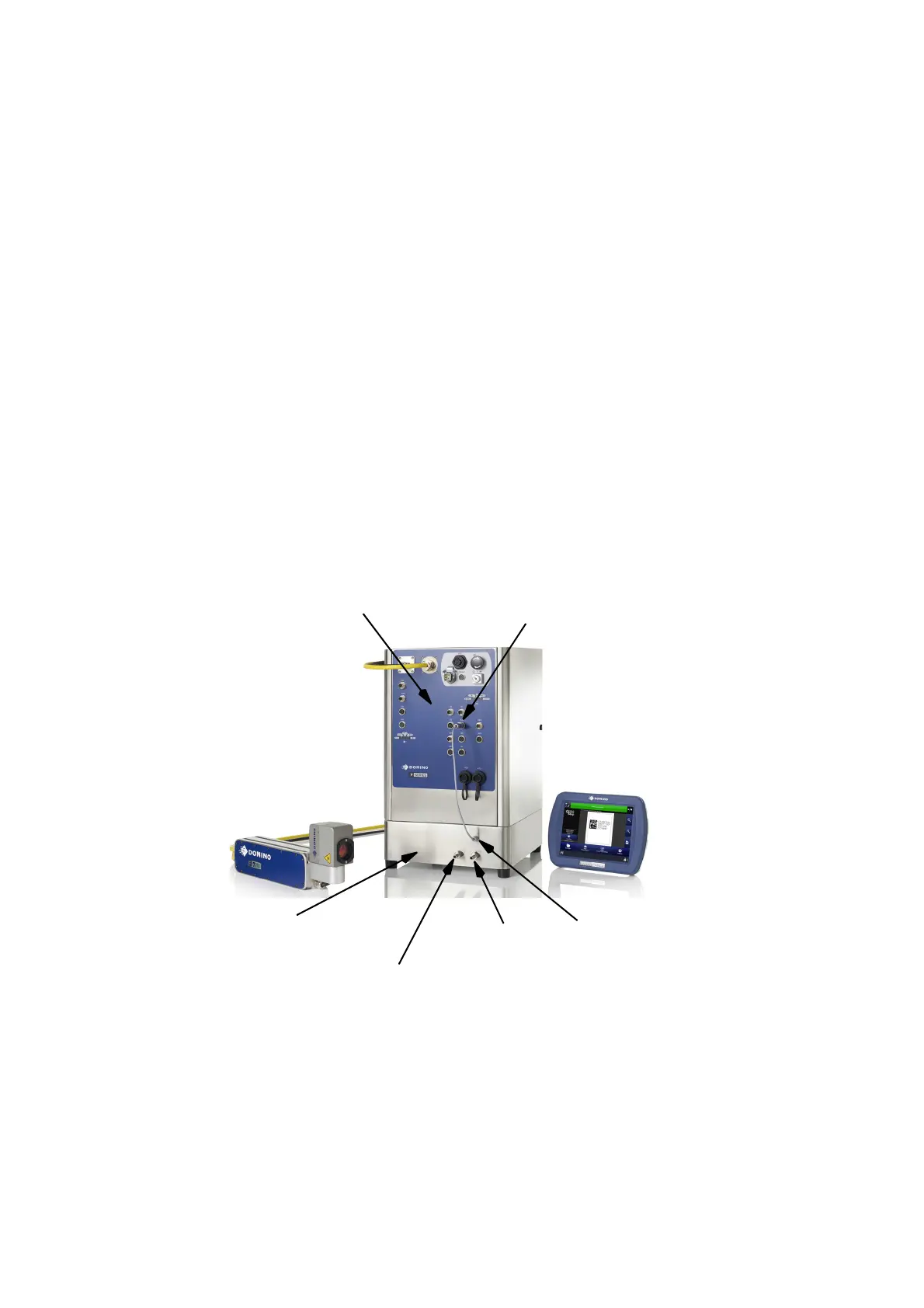

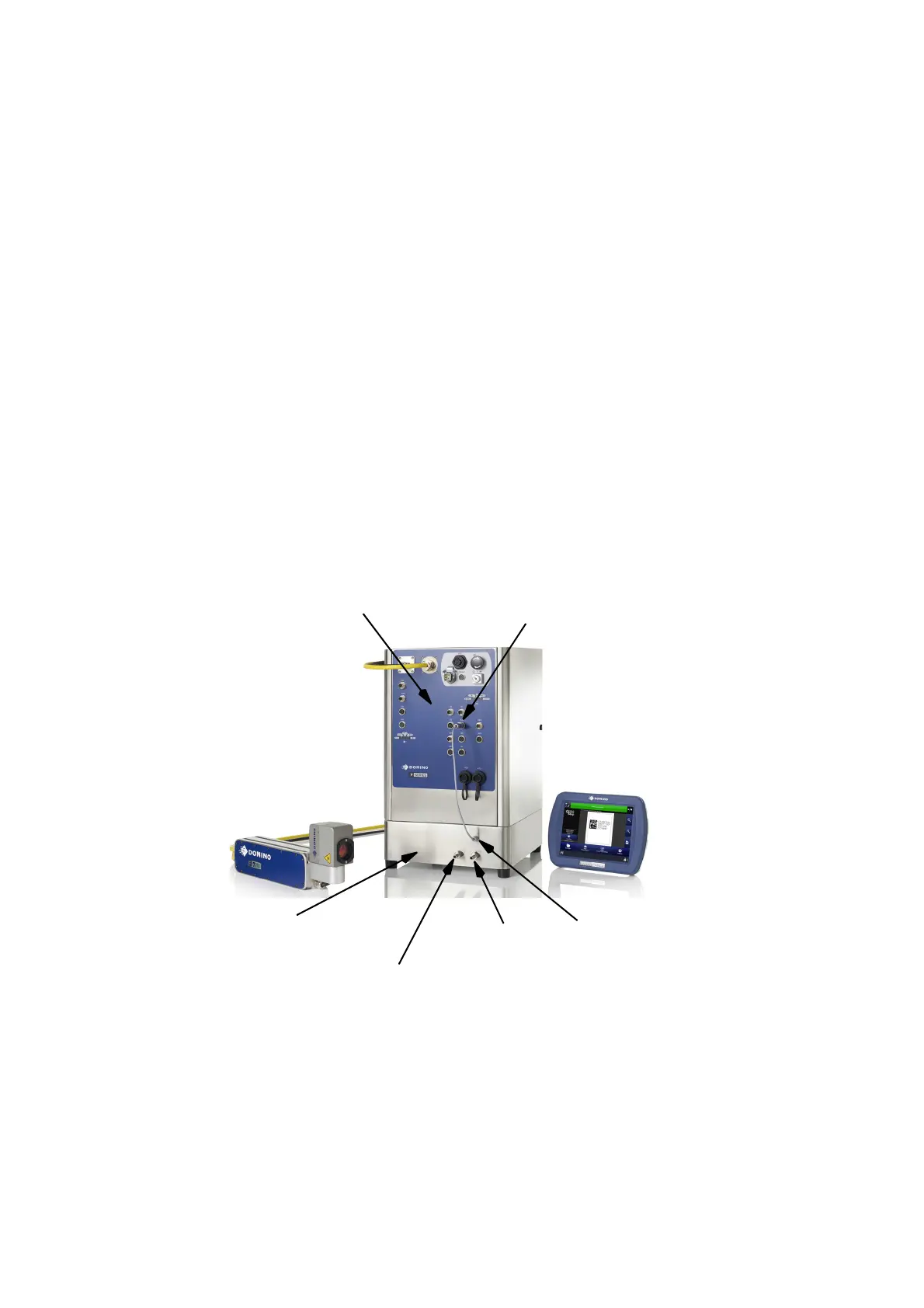

Water Cooling

A factory fitted option is available to cool the laser head and controller with

factory water or water from a water chiller. Use only clean and oil free water.

Hoses with an inner diameter from 3/8 inch (9.5 mm) to 10mm may be

used. Hoses have to be fastened with hose clamps.

Controller

X28 Connector

Water In

(Cold) (max. 5 bar)

Water Out

Water To Laser

(Hot)

Factory fitted option for

water cooling

X28 Connection

Loading...

Loading...