INSTALLATION INSTRUCTIONS

2-52 EPT031055 Issue 2 September 2017

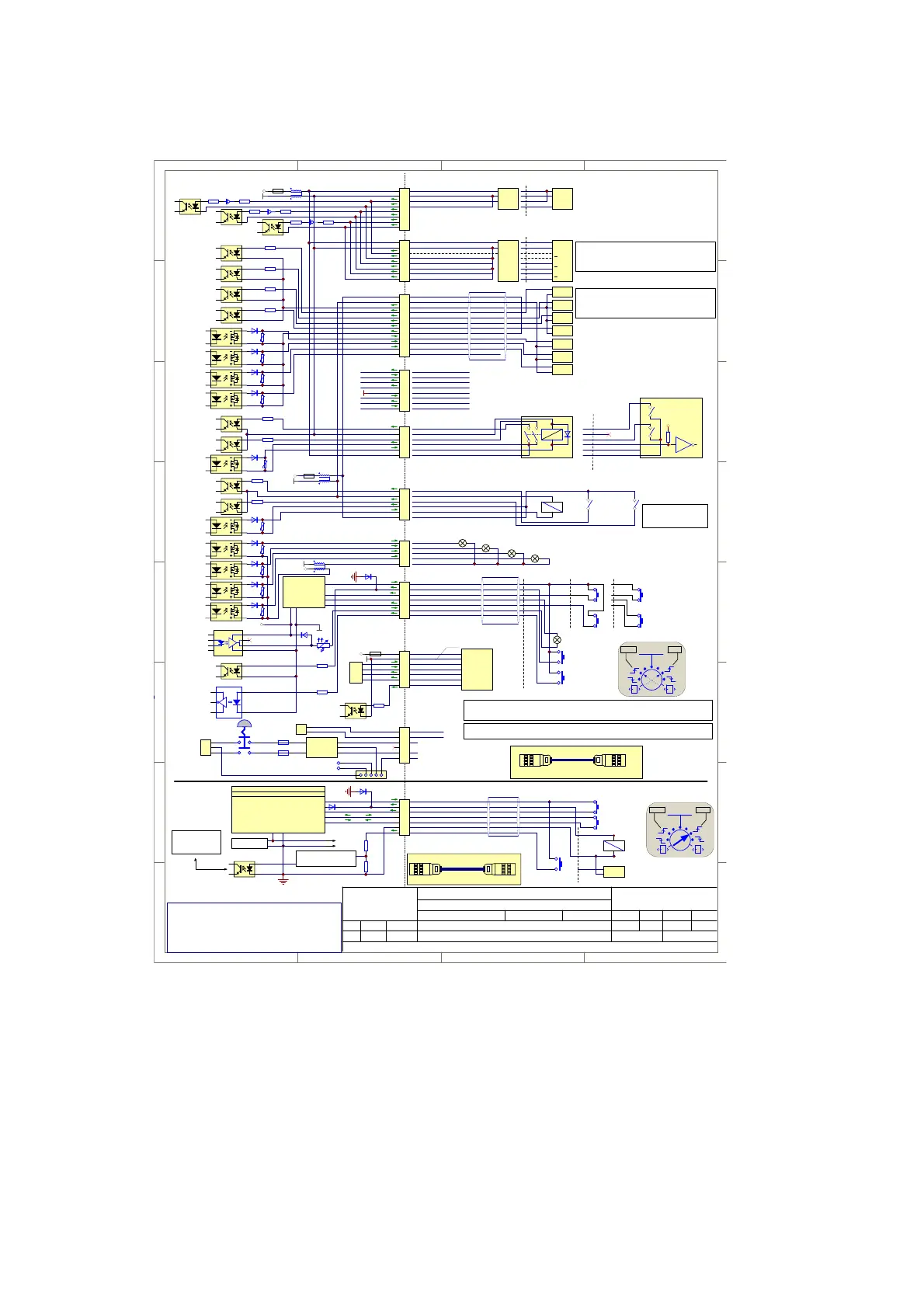

CONNECTOR OVERVIEW

1

1

2

2

3

3

4

4

H H

G G

F F

E E

D D

C C

B B

A A

Date Name Date Name

Ind. Chan.No. Changing Processed Reviewed

Title:

Project:

No.: 124714

BCP7 Electrical Connections

Valid from SCI 3.30 with fiber laser

bcp7_electrical_connections-1_07-124714b.SchDoc

Date

See box

File:

Version: See box Page of Size: A311

D-22547 Hamburg

Germany

Domino Laser GmbH

Fangdieckstraße 75a

© Domino Laser GmbH

A 1.00 created 28.02.12 PKU

A 1.01 X4 Description

23.10.12 PKU

A 1.02 added : values of the input resistors 25.10.12 PKU

A 1.03 add : mains power connection 110V /

230V 15.01.13 PKU

A 1.04 without Cat2, new:Cat3=PL_d; Cat4=PL_e (Performance-Level...) 26.03.13 MAU

a05: Including Interlock X69 (shutter /fiber laser version)

13.02.14

HK/PKU

a06 change externe signal designation / remove interne s.d. 24.06.14 PKU

b07 3.30 corr (fiber only: X29 > X69, lock coil diode) 17.11.14 HK

\\emea\group\Sator\R&D\Private\Elektronics\design\systems\bcp\bcp7\docu\bcp7_electrical_connections

1

2

3

4

5

6

7

X69

Laser Start

Print Go

L1_SOURCE

PRINT_GO

IL1_INP

PRINTER READY OUTPUT

EXT_LSTART_IN

Printer Ready

3

1

4

5

6

2

7

WH

BN

GN

YE

GY

PK

BU

PL_d PL_e

5

1

3

4

1

3

5

A

B

C

D

E

F

G

H

J

K

L

M

X4

1

2

3

4

5

6

7

8

X6

1

2

3

4

5

6

7

8

X3

100R

PD input

Enc A input

Enc B input

In order to use the shaft encoder as a print-go source ensure that pins 3

and 4 are connected.

WARNING: In this configuration no additional

product detector should be connected.

LASER_START

4K4

MARK_CONTROL

4K4

PRINT GO

4K4

PROG IN

4K4

PRINTER_READY

PRINTER_BUSY

COMPILE_OK

Logic Input

Logic Input

Logic Input

Logic Input

Logic Output

Logic Output

Logic Output

DCinputs: 10-30V/Rin 2,2K

DC outputs max 24V /max 500mA

Machine Interface X4

+

-

PLC

Output

+

-

PLC

Output

+

-

PLC

Output

+

-

PLC

Output

+

-

PLC

Input

+

-

PLC

Input

+

-

PLC

Input

INP_COM

LASER_START

MARK_CTRL

PRINT_GO

PROG_IN

OUT_+COM

PRINTER_READY

PRINTER_BUSY

COMPILE_OK

NC

+ Supply

0V

A

B

Z

+ Supply

0V

A

B

Z

Z

A

B

PNP

Encoder

Input mode

Differential (Standard)

Encoder

Input mode

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

*

Shaft Encoder Input X6

*

*

*

Product Detect Interface X3

PNP

+ Supply

0V

Q

1

2

3

4

NPN

+ Supply

0V

Q

1

2

3

4

PD+ Product Detect positiv input

+24V floating, max 120mA

GNDF - floating Ground

CustomerBCP7 Controller

GND

+24V

GND

+24V

*

1

2

3

4

5

X2

Logic Output

Logic Output

Logic Output

Logic Output

GND

+24V

BLUE (+24V output)

Beacon Interface X2

Blue

Amber

Green

Red

1

2

3

4

5

6

X28

4K4Input Air OK

4K4Input Chiller OK

Output Air/Chiller ON

AIR_OK

CHILLER_OK

CHILLER_AIR_ON_+COM

Air/Chiller Control X28

1

2

3

4

5

6

X7

4K4Input Vacuum OK

4K4Input Filter OK

Output Exhauster ON

VAC_OK

FILTER_OK

VAC_ON_+COM

VAC_ON_NO

Exhauster with Relay

+

Exhauster with Logic Input

GND

2

1

3

4

5

6

Vacuum Control X7

GND

1

2

3

4

5

6

7

8

X23

RTS - Request to Send

CTS - Clear to Send

DTR - Data Terminal Ready

GND - Ground

DSR - Data Set Ready

RXD - Receive Data

TXD - Transmit Data

DCD - Data Carrier Detect

RS232 Interface X23

Pilz PNOZ S4

PL_ePL_d

mode

In2+ In2-

AA

WH

BN

GN

YE

GY

PK

BU

RD

BK

VT

GY-PK

RD-BU

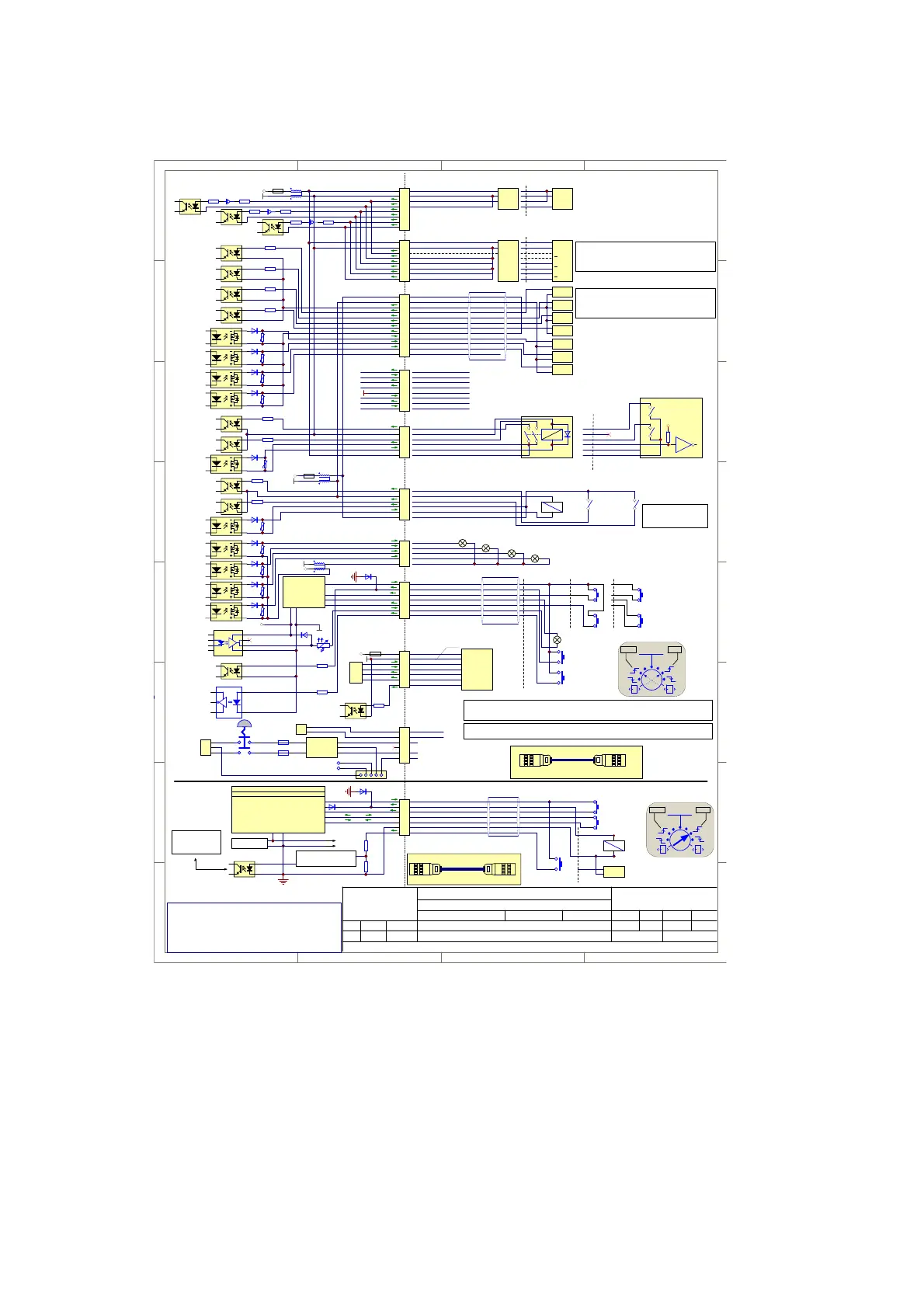

X58 is only suitable for controller interconnection. X58 is needed to connect the power extension box for

D620i systems. Do not connect anything else to this connector!

Depends on Dynamark options!

Default Air/Chiller Control X28

Laser ON = Air ON

Laser ON = Chiller ON

Air OK respectively

water level OK!

Chiller OK!

The main cable controller to laser is available in two versions:

Main cable BCP7 Cheetah / Harting-plug

Main cable BCP7 Cheetah / Toughcon-plug

1K

100R1K

100R1K

Ethernet 2 (Remote Panel Interface) X59

1

2

3

4

5

6

7

X59

TX+_Transmit+

TX-_Transmit-

RX+_Receive+

RX-_Receive-

LSTART_INP

Remote Panel

Power Input

for future application

S11

S12

S21

S22

Pilz PNOZ S4

A2A1

Printer Ready Output

N.C.

N.C.

Laser start Input

PG/ Trigger Input

Opto Coupler

GND

+24V

4K4

2K2

ETH Control

GND

+24V

TX+

TX-

RX+

RX-

4K7

Logic Input

1

2

3

4

5

PE

N

PE

BN

BU

GN/YE

RD

BK

EXT_L_PWR+

EXT_L_PWR-

1

2

Molex MiniFit SR-2

AC Power line (110/230V)

Harting HAN 3A/5

600V/16A

BU

BN

N

L

BU

BN

2B

1A

2A

1B

1

2

3

DIB-X5

Sabre-3

L

N

PE

PE Housing

PE Chassis

F1

F2

EXT_L_PWR

L-out

N-out

PE

L-in

N-in

GN/YE

GN/YE

GN/YE

GN/YE

1

2

3

4

5

6

7

X69

Laser Start

IL1_SOURCE +24V

IL1_INP

EXTERNAL LASER START INPUT

3

1

4

5

6

2

7

WH

BN

GN

YE

GY

PK

BU

PL_e

Pilz PNOZ S4

PL_ePL_d

mode

In2+ In2-

AA

Pilz mm0p

Programmed with shutter feedback verification

Safety 1 source

Safety 1 feedback

PSU 24V

+

-

4

3

1

2

U5

PC357N2TJ00F

Filter / input ref.1.6V /

start logic / driver

Via X68 to:

CP7 / X29 (floating

system)

To laser and board supply

X29X68

BCP7 ControllerFb-Laser Extension Box

DLG: 122383

Connect this cable for the shutter function

Door lock output

X24

X24

BCP7 ControllerFb-Laser Extension Box

DLG: 122384

Install this cable for the fiber laser internal data connection.

L2_GND

IL2_INP

DOOR LOCK OUTPUT

IL2 (a)

IL2 (b)

IL2 (a)

IL2 (b)

GND / PE

+

-

PLC

Output

7

2

6

Laser Start

Door lock (optional)

Interlock X69 (shutter version)

2.10 3.00

2.10 3.00

PD- Product Detect negativ input

PD+ Product Detect positiv input

+24V floating, max 120mA

GNDF - floating Ground

PD- Product Detect negativ input

CHA+ Encoder Channel A positiv input

CHB+ Encoder Channel B positiv input

CHA- Encoder Channel A negativ input

CHB- Encoder Channel B negativ input

+24V floating

GNDF - floating Ground

GNDF - floating Ground

+24V floating

GNDF - floating Ground

CHILLER_AIR_ON_NO

+24V floating

GNDF - floating Ground

AMBER (+24V output)

GREEN (+24V output)

RED(+24V output)

+24V floating

GNDF - floating Ground

L

Interlock X69 (NO shutter version)

Case GND

Case GND

Loading...

Loading...