2. Pipe design

2-1. Important items when using refrigerant (R410A)

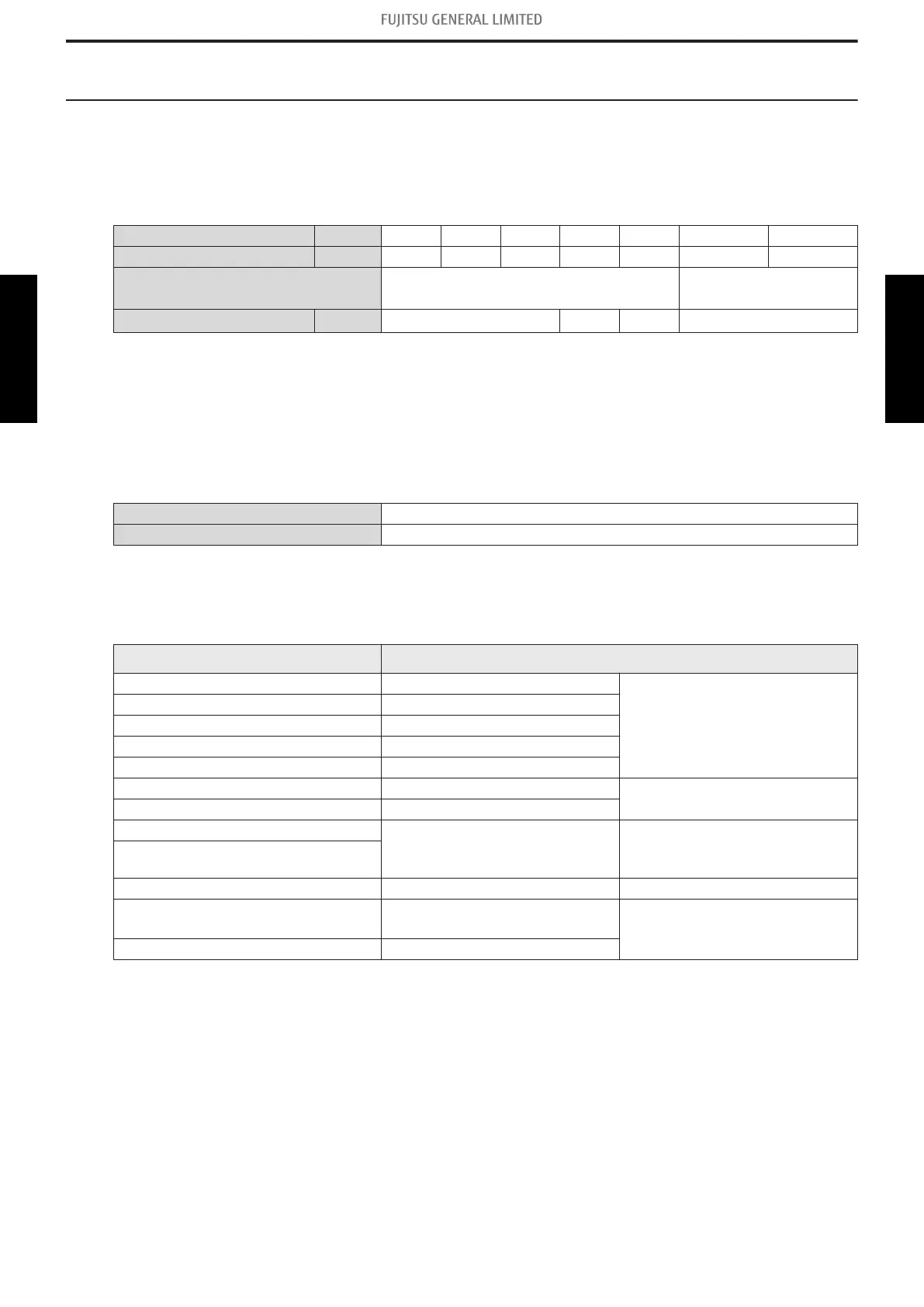

• Refrigerant piping material and wall thickness

It is necessary to use seamless copper tubes for refrigerant use. Thickness of tubes are shown in

table below.

Nominal diameter in 1/4 3/8 1/2 5/8 3/4 7/8 1-1/8

Outside diameter mm 6.35 9.52 12.70 15.88 19.05 22.22 28.58

Material

JIS H3300 C1220T-O or equivalent*

1

JIS H3300 C1220T-H

or equivalent*

2

Wall thickness*

3

mm 0.8 1.0 1.2 1.0

*1: Allowable tensile stress ≥ 33 N/mm

2

*2: Allowable tensile stress ≥ 61 N/mm

2

*3: Endurance pressure of the pipes: 4.2 MPa

Select the pipe size in accordance with local rules.

• Lubricant

Refrigerant R410A (Mixed refrigerant)

Lubricant Synthetic oil

• Tools

R410A work requires a number of special tools. Since the tools (with * symbol) for R22 work can-

not be used for R410A, prepare them beforehand.

Tool name Process and application

Pipe cutter Pipe cutting

Refrigerant piping work

Flaring tool* Pipe flaring work

Torque wrench* Flare nut connection

Expander Expansion at pipe connection

Pipe bender Pipe bending work

Nitrogen gas Pipe interior oxidation prevention

Air tightness test

Welder Pipe brazing

Gauge manifold* Vacuum evacuation and

refrigerant charging operation

check

Air tightness test ~ Refrigerant

additional charging

Charging hose*

Vacuum pump (with adapter)* Vacuum drying

Electronic scale for refrigerant

charging

Refrigerant additional charging

Gas leak tester* Gas leakage test

*: For details, refer to the service manual.

- 179 -

2-1. Important items when using refrigerant (R410A) 2. Pipe design

SYSTEM

DESIGN

SYSTEM

DESIGN

Loading...

Loading...