3. Pipe installation

3-1. Caution of piping

CAUTION

Keep the permissible length of every piping limitation to prevent a defect or cooling/heating

failure.

• Piping material:

– Use the designated size (diameter and thickness) of refrigerant pipes.

– Those pipes purchased locally may contain dust inside. Blow out the dust by dried inert gas

when using.

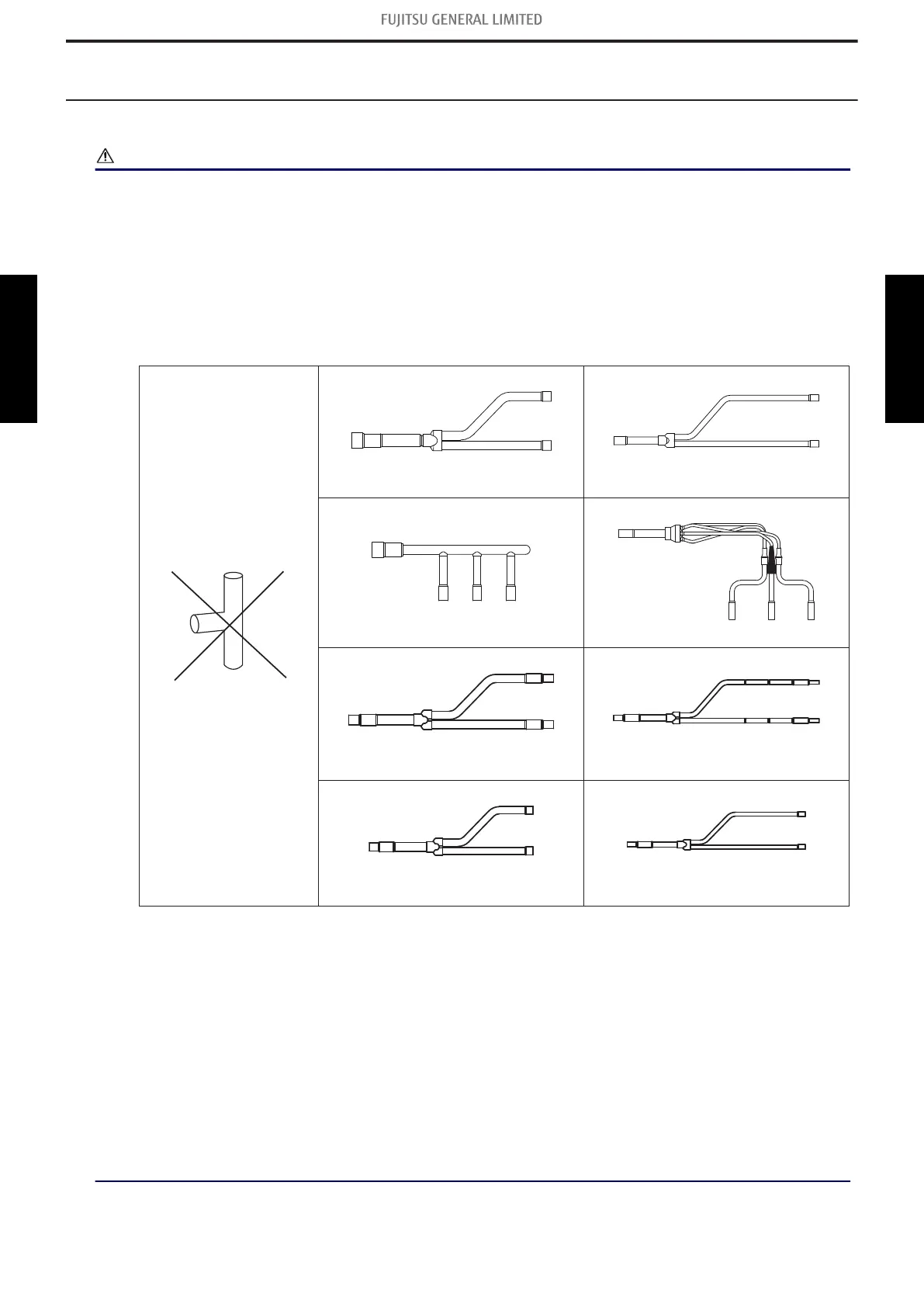

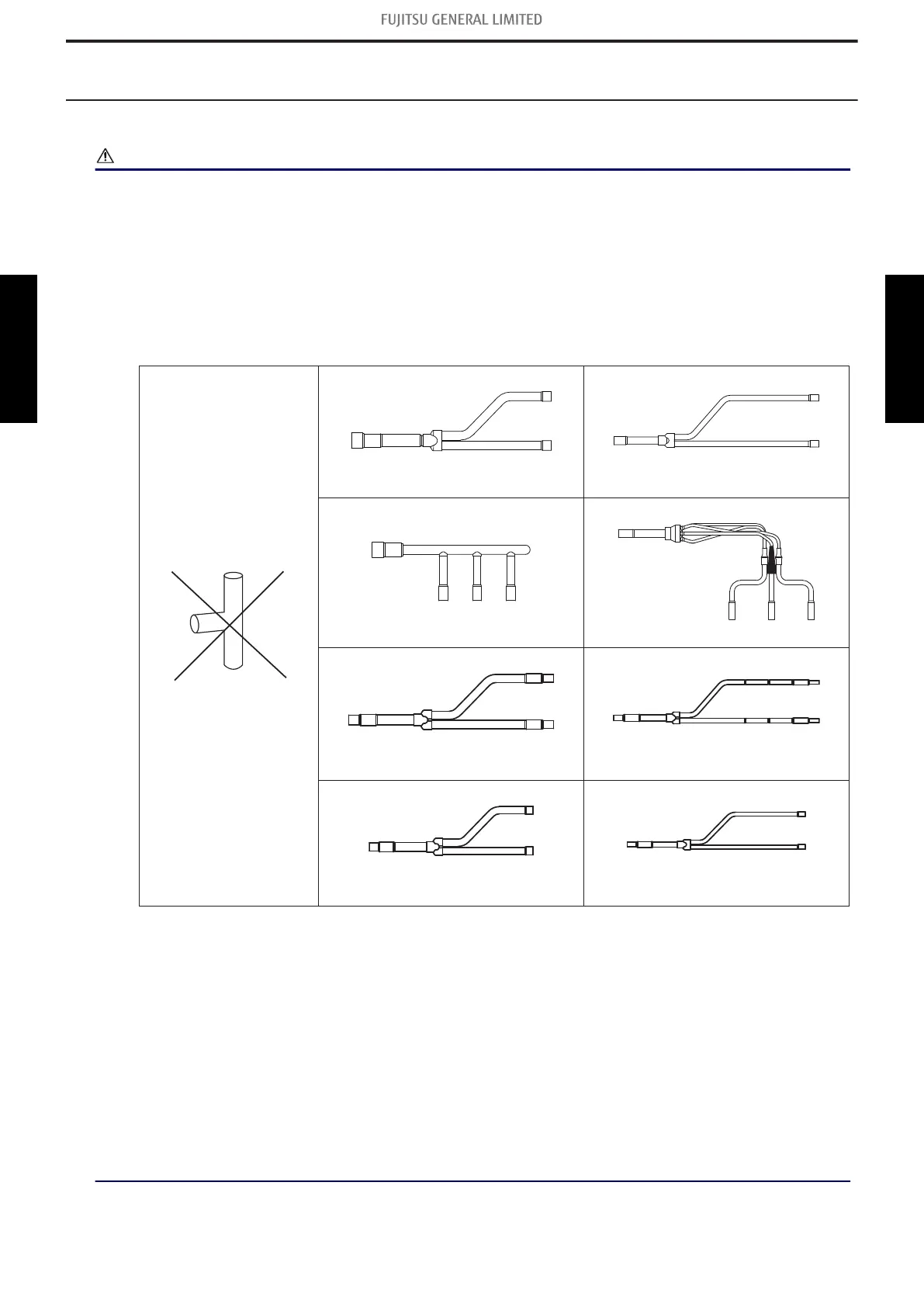

– To process the branch, do not use T-shaped pipe, which causes a uneven refrigerant flow.

Use the optionally available standard branch pipe.

T-tube

UTP-SX272A (Gas)

UTP-SX272A (Liquid)

Twin connection type

Double twin connection type

Twin connection type

Double twin connection type

UTP-SX372A (Gas)

UTP-SX372A (Liquid)

Triple connection type Triple connection type

UTP-SX236A (Gas)

UTP-SX236A (Liquid)

Double twin connection type

for 72 model

Double twin connection type

for 72 model

UTP-SX254A (Gas)

UTP-SX254A (Liquid)

Double twin connection type

for 90 model

Double twin connection type

for 90 model

– When replacing the unit, never use piping which has been used for previous installations. On-

ly use the new piping.

• Piping process stage:

– Be careful to avoid the dust or water falling into the pipe when preforming pipng process and

piping installation.

– When processing the pipe, make the number of bending portion as few as possible, and the

bending radius as large as possible.

– If the diameter of the required pipe is different from the branch unit, either cut it out or use the

reducer.

(continued)

- 195 -

3-1. Caution of piping 3. Pipe installation

SYSTEM

DESIGN

SYSTEM

DESIGN

Loading...

Loading...