SERVICE SCHEDULE 9

35

9.1 Additional information

Any further work that results from the compulsory work or from the recommended work must be ordered sepa-

rately and invoiced separately.

Different service intervals may apply in your country, depending on the local operating conditions.

Individual service intervals and scopes may change in the course of technical developments. The most up-

to-date service schedule can always be found on Husqvarna Motorcycles Dealer.net. Your authorized Husq-

varna Motorcycles dealer will be glad to advise you.

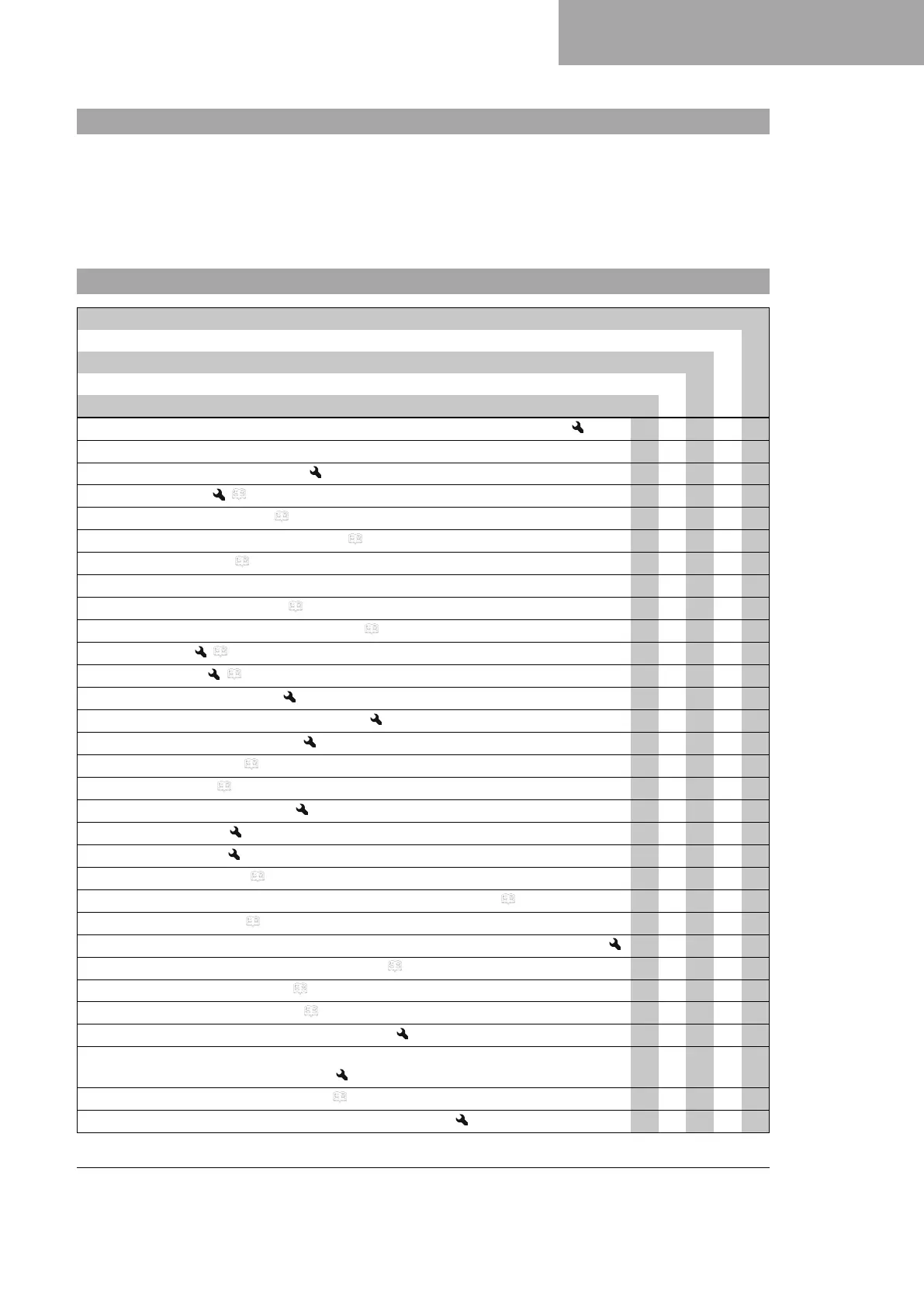

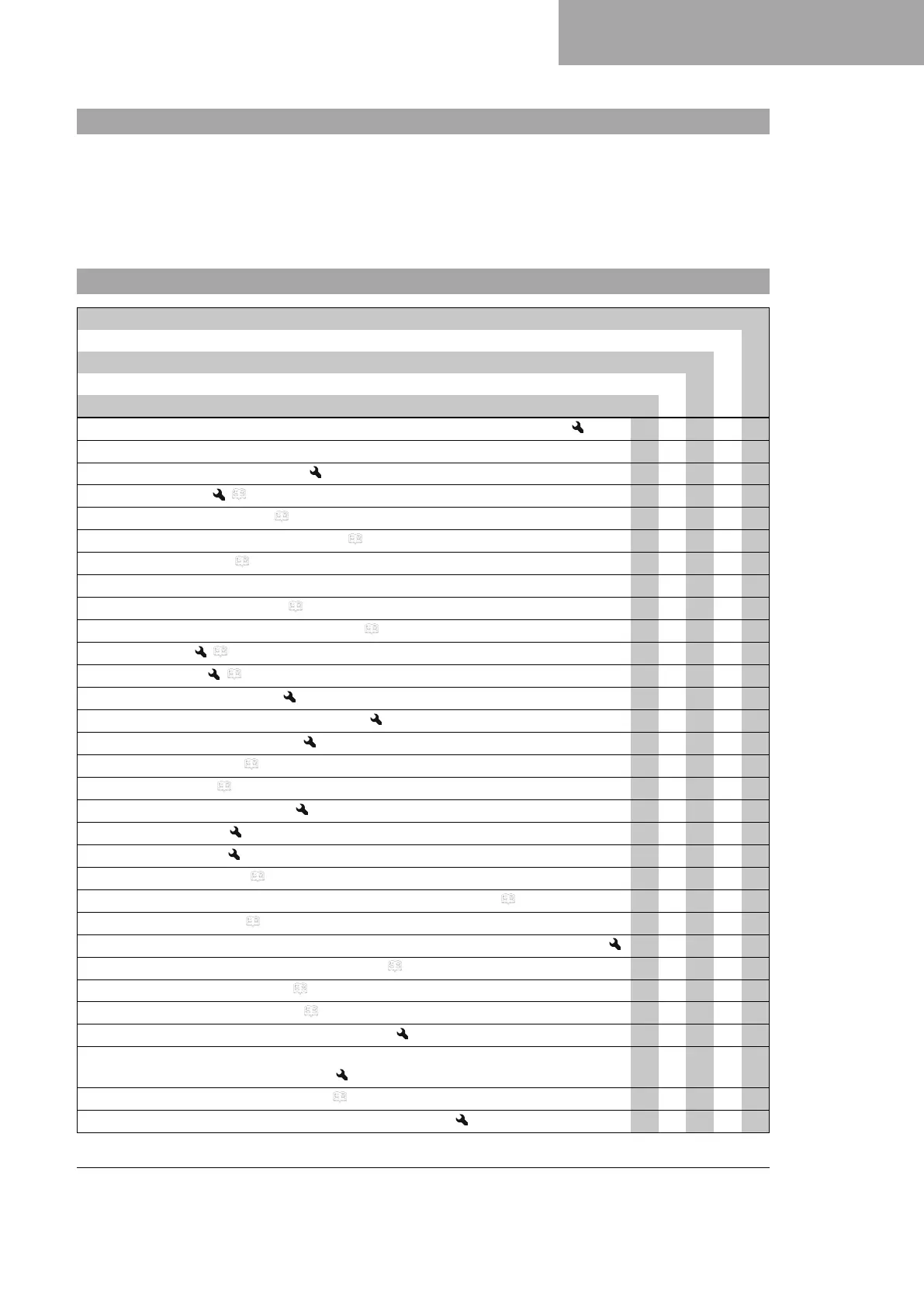

9.2 Required work

Every 40 operating hours

Every 20 operating hours

Every 10 operating hours

After 5 operating hours

After 1 operating hour

Read out the fault memory using the Husqvarna Motorcycles diagnostics tool. ○ ○ ● ● ●

Check that the electrical system is functioning properly. ○ ● ● ●

Check and charge the 12-V battery. ● ● ●

Change the gear oil. ( p. 121) ○ ●

Check the front brake linings. ( p. 83) ● ● ●

Check the brake linings of the rear brake. ( p. 89) ● ● ●

Check the brake discs. ( p. 81) ● ● ●

Check the brake lines for damage and leakage. ● ● ●

Check the rear brake fluid level. ( p. 87) ● ● ●

Check the free travel of the foot brake lever. ( p. 86) ● ● ●

Check the frame. ( p. 76) ● ● ●

Check the link fork. ( p. 76) ● ● ●

Check the fork bearing for play. ● ●

Check the shock absorber heim joint for play. ● ● ●

Check the shock absorber linkage. ● ● ●

Check the tire condition. ( p. 96) ○ ● ● ●

Check tire pressure. ( p. 96) ○ ● ● ●

Check the wheel bearing for play. ● ● ●

Check the wheel hubs. ● ● ●

Check the rim run-out. ○ ● ● ●

Check the spoke tension. ( p. 97) ○ ● ● ●

Check the chain, rear sprocket, engine sprocket, and chain guide. ( p. 74) ● ● ●

Check the chain tension. ( p. 72) ○ ● ● ●

Grease all moving parts (e.g., hand lever, chain, ...) and check for smooth operation. ● ● ●

Check/correct the fluid level of hydraulic clutch. ( p. 78) ● ● ●

Check the front brake fluid level. ( p. 82) ● ● ●

Check steering head bearing play. ( p. 56) ○ ● ● ●

Change the spark plug and spark plug connector. ● ●

Check all hoses (e.g. fuel, cooling, bleeder, drainage hoses, etc.) and sleeves for

cracking, tightness, and correct routing.

○ ● ● ●

Check the antifreeze and coolant level. ( p. 104) ○ ● ● ●

Check the cables for damage and for routing without kinks. ● ● ●

Loading...

Loading...