100 HyPrecision 50S/60S/75S Operator Manual 808690

5 – Preventive maintenance

Preventive maintenance

Disassemble the intensifier

Refer to the Intensifier parts section on page 127 for part numbers. Refer to

page 149

for ordering

information.

Remove the output adapter and the high-pressure poppet assembly

The high-pressure poppet seat can cause cracks, erosion marks, or indents in the output adapter.

Required parts, tools, and materials

Clean, lint-free towels

Isopropyl alcohol

1-inch open-ended wrench

15564 6-inch cotton-tipped applicator

1. Use an open-ended wrench to loosen the output adapter. Remove the output adapter from the check valve.

2. Use a cotton-tipped applicator to guide the high-pressure poppet seat out of the check valve. Tap the output

adapter gently on a wooden or other soft surface to eject the poppet from the output adapter.

3. Clean each part with a lint-free towel and isopropyl alcohol. Examine all parts for deterioration, corrosion, or

damage.

Repair or replace parts identified in the preventive maintenance schedule or if the parts show

deterioration, corrosion, or damage.

Examine parts that are being replaced to identify wear patterns or damage that can indicate other

problems

If any of the poppet parts are damaged, replace all 3.

Service Interval

Replace the high-pressure poppet assemblies After every 1,000 hours of operation

Replace the output adapters After every 6,000 hours of operation

Do not use soap, detergent, or solvents.

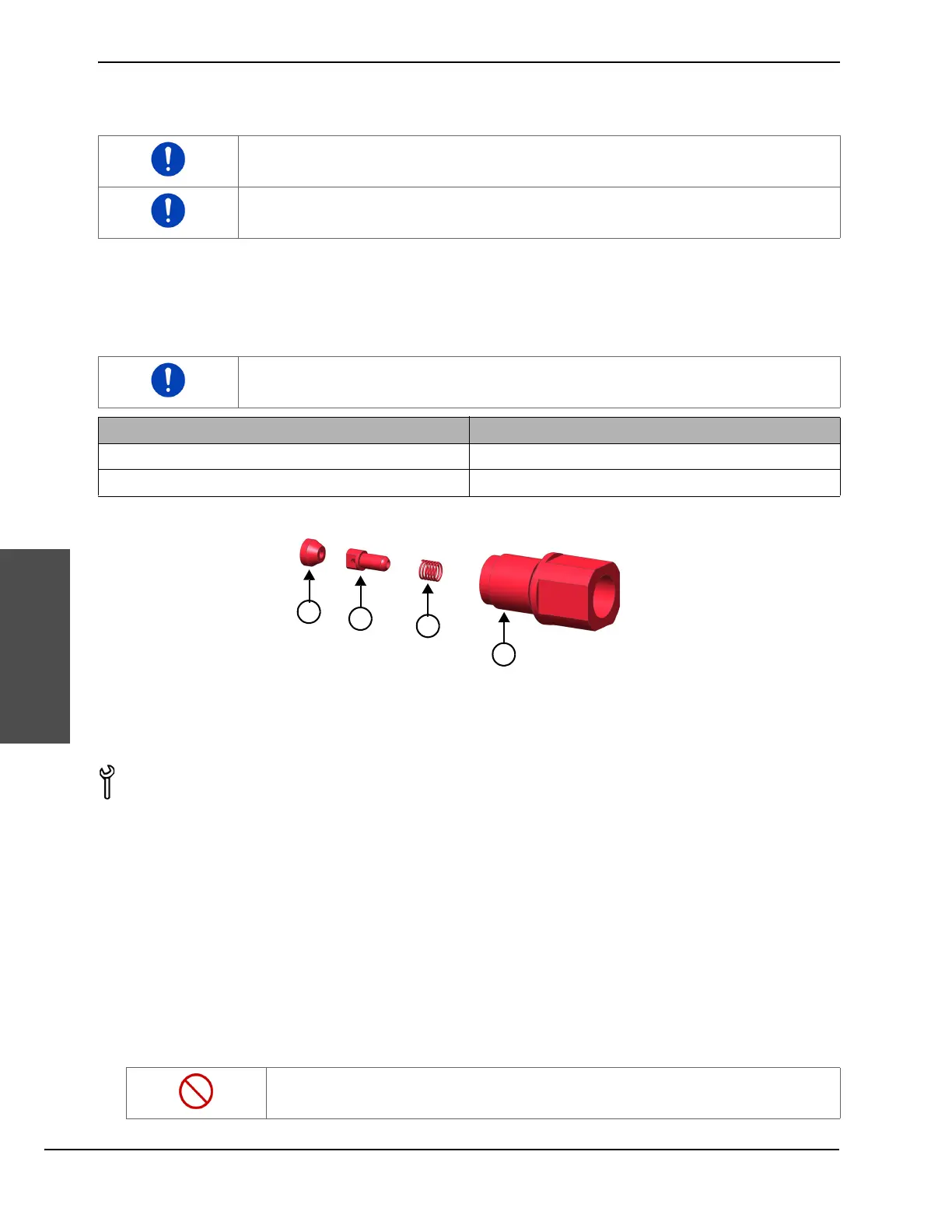

1 High-pressure poppet seat

2 High-pressure poppet

3 High-pressure poppet spring

4 Output adapter

Loading...

Loading...